5 operation – Analytical Industries AII-3000 M Series Portable Oxygen Analyzer User Manual

Page 10

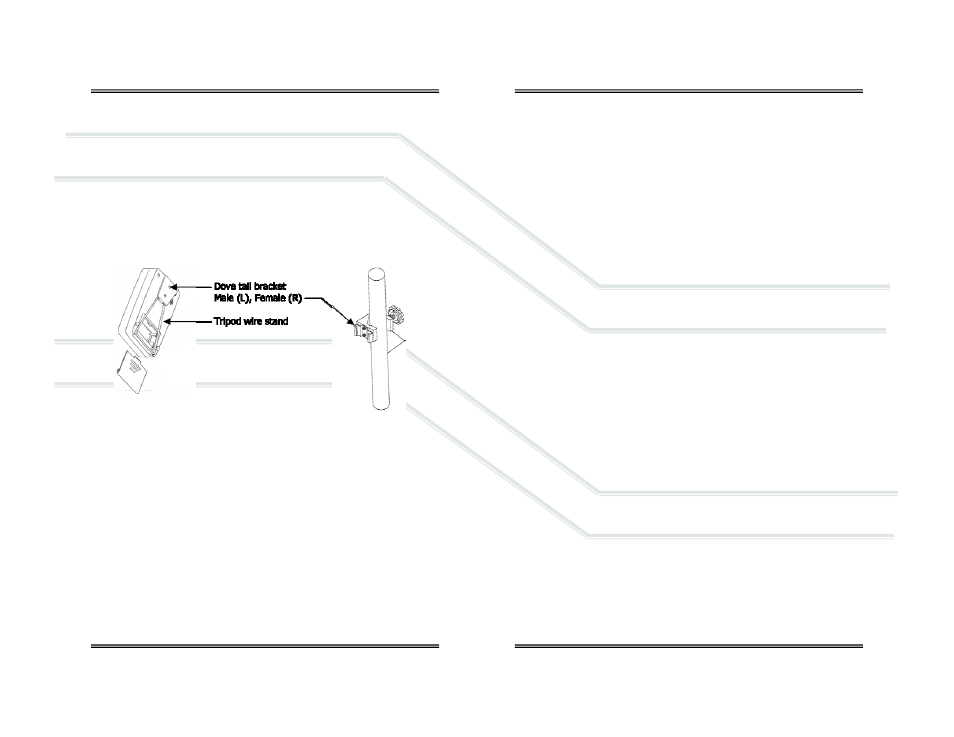

4.8 Mounting

Every analyzer and monitor is equipped with a male dove tail bracket and

triangular shaped thick metal wire stand secured to the rear of the enclosure.

Tripod Wire Stand

Secured between bumper feet on either side of the battery compartment is a

triangular shaped thick metal wire stand that is hinged under the dove tail

bracket secured at the opposite end of enclosure.

Unsnap the triangular thick metal wire stand from between the bumper feet

and pull it away from the enclosure to form a tripod which allows the device to

sit upright on any flat surface

Dove Tail Bracket

The male dove tail bracket is secured to the rear of the enclosure with two

screws. The 1” female dove tail pole bracket (HRWR-1075) is an optional ac-

cessory that is commonly found in medical applications. The v-shaped male

component simply slides into and out of the pole mounted female section.

16

5 Operation

5.1 Principle of Operation

The AII-3000 Series Oxygen Analyzers utilize an electrochemical galvanic fuel

cell type oxygen sensor of the type that is extensively used to measure oxygen

concentrations from 0% to 100% in gas streams. Oxygen, the fuel for this

electrochemical transducer, diffusing into the sensor through a gas permeable

membrane reacts chemically at the sensing electrode to produce an electrical

current output proportional to the oxygen concentration in the gas phase. The

sensor has an absolute zero meaning that when no oxygen is present to be

chemically reacted the LCD displays 00.0 oxygen.

The sensor’s signal output is linear over the entire range, remains virtually con-

stant over the specified useful life and drops off sharply at the end. The sensor

itself requires no maintenance and is simply replaced at the end of its useful life

like a battery. Inasmuch as the sensor is a transducer in its own right, its ex-

pected life is not affected by whether the analyzer is ON or OFF.

The relationship between the sensor’s signal and changes with the oxygen

concentration is both proportional and linear, thus allowing single point calibra-

tion. Other factors that can affect the signal output are described in Section 5.2

Application Considerations and Section 3 Safety Warnings which should be read

before use.

Historically, the expected life of galvanic fuel type sensors has been specified as

“in air (20.9% O

2

) at 25°C and 760mm Hg”. The actual life of any galvanic fuel

type sensor is inversely affected by changes in the average oxygen concentra-

tion, temperature and pressure it is exposed to during its useful life. For exam-

ple, the AII-11-60 sensor has a 60 months expected life in air (20.9% oxygen)

at 25°C and ambient pressure, however, in a 100% oxygen atmosphere the

expected life is 12.6 months [60mo/(100%/20.9%)].

AII-3000 Series Oxygen Analyzers are battery powered by (2) AA alkaline bat-

teries and controlled by a state-of-the-art microprocessor. The batteries provide

enough power to operate the analyzer continuously for approximately 1,200

hours. Both devices utilize a membrane type keypad for users to communicate

commands to the microprocessor. The monitor is menu driven to accommodate

the alarm functions. The digital electronics provide features such as system

diagnostics, warning indicators, controls and an alarm capability for continuous

monitoring that enhance both safety and effectiveness. The design criteria,

quality program and performance features ensure reliable and accurate oxygen

measurements.

17