Advanced instruments inc – Analytical Industries GPR-1535 GB Trace PPM Oxygen Transmitter User Manual

Page 10

Advanced Instruments Inc.

10

Connections – Optional Intrinsic Safety Barrier:

See attached addendum

Hazardous Area Operation:

When used in conjunction with the optional intrinsic safety barriers, the design of the GPR-1535 GB meets recognized standards

as intrinsically safe for operation in Class I, II, III; Division I, II; Groups C-G hazardous areas. Note: Locate the optional

intrinsic safety barrier as close to the power source in the non-hazardous area as possible.

The GPR-1535 GB is also available in a version, requiring optional intrinsic safety barriers, that has been certified to ATEX

Directive 94/9/EC, Ex II 1 G Ex ia IIB T4 Tamb -20⁰C to + 50⁰C

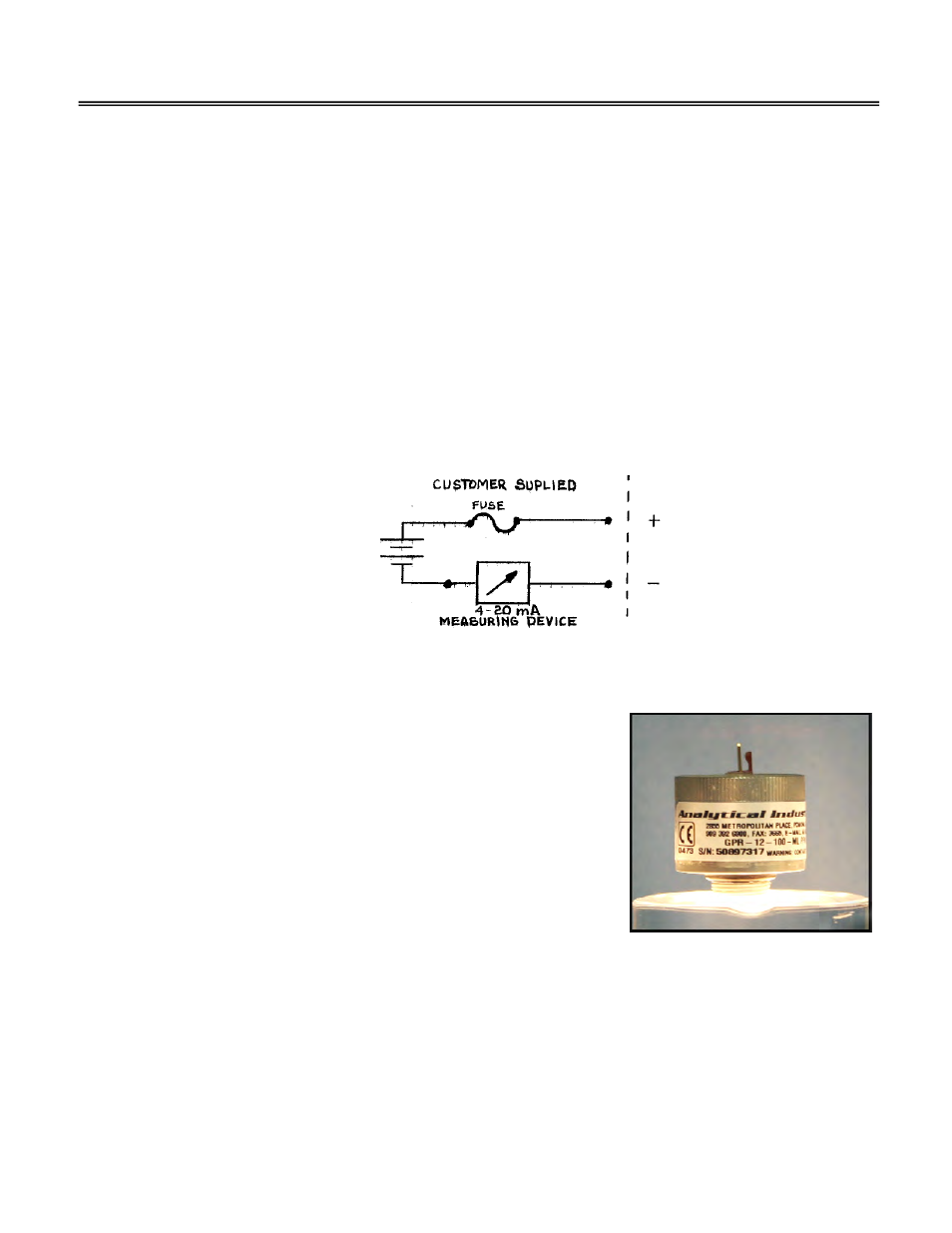

Output connection:

The 4-20mA current output is obtained by connecting the current measuring device between the negative terminal of power

source and the negative terminal, marked (-), located in the junction box of the transmitters. The positive current flow is from

pin 1 to pin 2 and from pin 2 to ground through the external load.

To check the signal output of the 4-20mA E/I integrated circuit connect an ammeter, as illustrated below, as the measuring

device and confirm the output is within +0.1mA of 4mA.

Power 12-28V DC To Transmitters

Terminal Strip

Caution: To assure proper grounding, connect the 4-20mA signal output to the external device (PLC, DCS, etc.) before

attempting any zero or span adjustments.

Installing the Oxygen Sensor

The GPR-1535 GB ppm Oxygen Transmitters are tested and calibrated by the

manufacturer prior to shipment and accompanied by the qualified PPM oxygen sensor

package in a separate shipping container.

Caution: All transmitters must be calibrated once the installation has been completed

and periodically thereafter as described below. Following the initial installation and

calibration, allow the transmitters to stabilize for 24 hours and calibrate with certified

span gas.

Procedure:

1. Caution: Do not change the factory settings until instructed to do in this manual.

2. Open the barrier bag containing the new sensor.

3. If the sensor is equipped with a shorting loop, remove the shorting wire from the

pins of the female socket attached to the new sensor.

4. Align the holes and tabs of the female connector with the 4 pins and vertical support of the male connector.

5. Push the female connector with the wire cable to the cable onto the male section until they snap together.

6. Initial installation, air calibration is recommended, however, span gas calibration is at the user’s discretion.

7. Once the reading stabilizes, calibrate the transmitter as described in section 5 Operation Span Calibration.

8. Once calibrated, temporarily separate the connectors and disconnect the sensor.

9. Immediately screw the sensor, finger tight plus 1/2 turn, into the flow housing and reconnect the sensor.

10. The analyzer will OVER RANGE for a short period of time as indicated by the graphical LCD display.

11. Following calibration immediately introduce or expose low PPM gas, either sample or zero gas, to the sensor.