Derale Performance 25 Row Hyper-Cool Remote Cooler, -6AN User Manual

Diagram #2, Diagram #1, Diagram #2 diagram #3

13760-InstructionSheet

Derale Performance, Los Angeles, CA

800.421.6288 www.derale.com

INSTALLATION INSTRUCTIONS

HYPER-COOL REMOTE COOLER

PART # 13760

KIT CONTENTS

QTY. DESCRIPTION

1

Oil Cooler Assembly

2

-6AN Female x 3/8” Hose Barb Adapter

2

-6AN x 7/8”-14 O-ring Male Adapter

Please read these instructions completely before starting the installation.

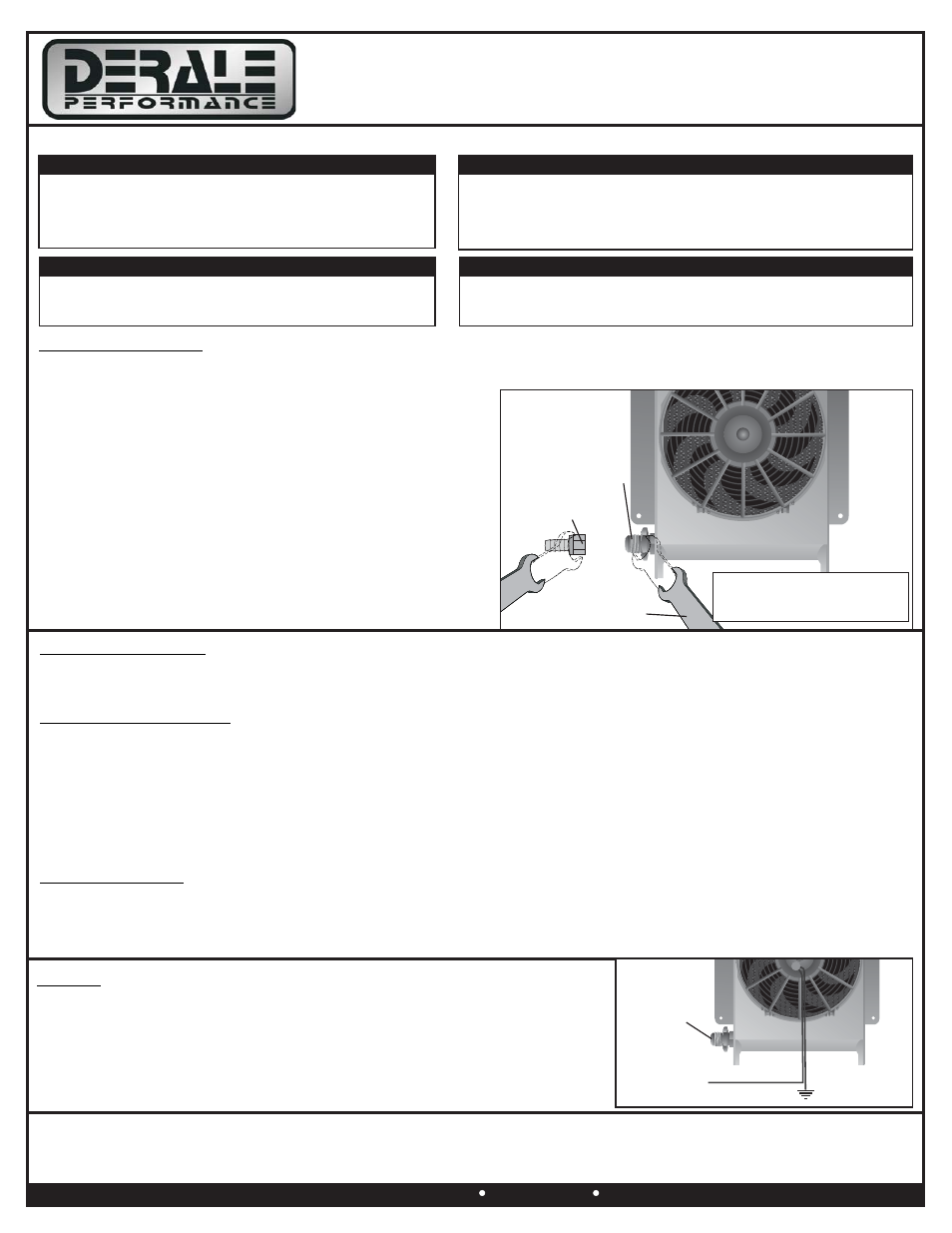

Always use backup wrenches when tightening fittings.

The AN fittings supplied in this kit do not require any thread

sealant. (See Diagram #1)

Standard Screw Driver

or 5/16” Nut Driver

7/16” Socket & Ratchet

Open End Wrench’s

Teflon Tape

Razor Knife

Marker

Drill

9/32” Drill Bit

TOOLS NEEDED

Warning: Installation of accessories should only be undertaken by those with mechanical knowledge and are familiar with working on

vehicles. Always use eye protection (goggles, safety glasses or shield). Park the vehicle in a well lit area, on level ground and apply the

parking brake. Only work on a cold vehicle that has been sitting overnight, failure to do so will result in severe burns and injury. Before starting

the vehicle, make sure no tools or any other items are left under hood that could interfere with or be drawn into moving parts of the engine.

Failure to follow instructions can lead to severe damage and personal injury.

WIRING

(See Diagram # )

5.3 Amps

Before beginning reference the Product Label on the Electric Fan

shroud for the factory PULLER fan configuration Positive wire color. If you wish to

configure the fan opposite of the factory PULLER setting, The Positive (+) and

Negative (-) wires MUST be switched.

Hook the Positive (+) wire to a switched 12 volt source (Manual Switch or Thermostat).

Hook the Negative (-) wire to a good chassis Ground (-).

2

Specifications- Electric Fan rating:

Important:

Transmission

Power Steering

Fuel

RECOMMENDED FOR

PRE-INSTALLATION

Important:

This fan is factory setup for PULLER applications

Changing airflow direction

Note:

The Electric Fan comes from the factory with a product label installed on one end of the fan shroud. Before installation

check the product label to confirm airflow direction & positive electric fan lead color. Airflow direction will be shown with an arrow.

To change the airflow direction from the factory setting:

1.

Using a 7/16” Socket & Ratchet, remove the four 1/4-20 lock

nuts holding the Electric Fan onto the Oil Cooler Assembly.

2.

Remove the Nut or Clip that holds the electric fan blade onto

the motor shaft.

3.

Carefully remove the fan blade from the motor shaft.

This is an interference fit and requires some effort.

4.

Flip the fan blade upside down and reinstall onto the motor

shaft. Make sure the roll pin on the motor shaft is aligned with

the slot on the fan blade.

5.

Reinstall nut or clip on motor shaft.

6.

Reinstall the Electric Fan onto the Oil Cooler Assembly.

COOLER LOCATION

COOLER INSTALLATION

ROUTING HOSES

The purpose of a remote mount cooler is to be able to mount the cooler away from the front of the vehicle therefore not blocking

airflow to the radiator/condenser. This cooler can be mounted anywhere space permits. Always keep in mind that the cooler still

needs access to airflow to perform at its peak.

(MOUNTING HARDWARE NOT INCLUDED)

1. Identify the two -6AN x 7/8” Male Adapters.

2. Install the fittings onto the cooler with the o-ring side toward the cooler.

Thread sealant is not necessary on o-ring fittings.

3. Using a 1 1/8” Open End Wrench, tighten fittings.

4. Included in this kit are two adapter fittings which allow the AN fitting to be converted to hose barb. (See Diagram #1)

5. Hold the Oil Cooler Assembly in the desired location.

6. Using a marker, mark the four hole locations.

7. Using a drill and 9/32” drill bit, drill the four mounting holes.

8. Using 1/4”-20 Bolts, 1/4” Washers & 1/4” Lock Nuts (Not Supplied) attach the Oil Cooler Assembly.

The Cooler core will flow in either direction, there is no specified inlet or outlet port.

When routing hoses, be sure to keep all hoses away from sharp edges, moving parts and hot engine components.

Hoses should be routed carefully and should not be bent in less than a 5” radius.

A kinked hose will restrict flow and could cause failure.

Note:

Note:

Warning:

Important:

IMPORTANT

Inlet

Ground

Diagram #2

Diagram #2

12V

Positive (+)

-6AN x 7/8”

Male Adapter

Diagram #1

Diagram #1

Backup

Wrench

WARNING:

DO NOT TIGHTEN WITHOUT

BACKUP WRENCH!

-6AN Female x 3/8”

Hose Barb Adapter

Diagram #2

Diagram #3