MAX Power VIP 150 Electric Retractable Thruster User Manual

Page 5

VIP 150, 12/24V with Electronic Controller

.

25/12/05

5

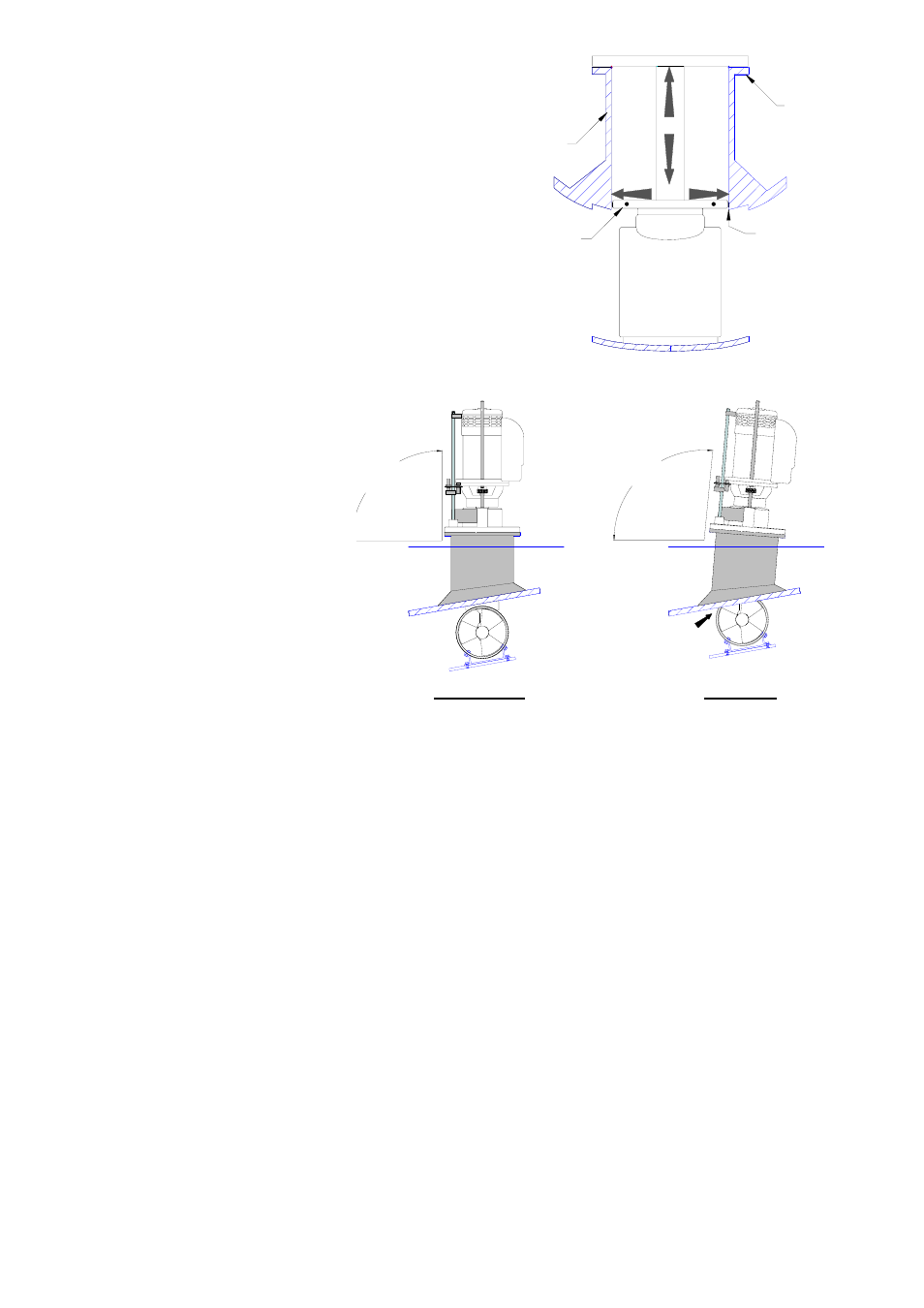

( a )

( b )

< 2 mm

Thrust Plate

Mounting

Base

Mounting

Base

Flange

90°

CORRECT

Water

Line

Water

Line

Not 90°

WRONG

Before fixing the thruster unit onto the mounting base flange it is important to ensure

that the top surface of the mounting base flange is perfectly flat in order to accept the

« O » ring seal of the VIP base flange in order to ensure perfect water tightness.

The bolts fixing the VIP onto the mounting flange must be inserted from top to bottom.

Provide sufficient access underneath the flange to allow for tightening the nuts. If the

access is not possible, provide a special mounting flange with metric studs or tapped

holes.

The VIP pushes its thrust plate sideways

against the inside of the mounting base

when running. This means that one must

totally lower the unit and check the

following:

(a)

That the VIP’s thrust plate is free to

move up and down.

(b)

And also that there is no more than

2mm horizontal movement

between the thrust plate and the

mounting base, especially when

fully down.

The mounting base

flange should be parallel

to the waterline.

In other words the

thruster unit must be

installed vertical with its

turbine totally clear of

the hull in the down

position.