Sliding plates – MAX Power COMPACT User Manual

Page 8

English Manual: Compact Retract 12/24V, Version 2

14/04/2005

Thruster

Unit

Sliding

Plates

249mm

at top

249mm

at bottom

( d )

( d )

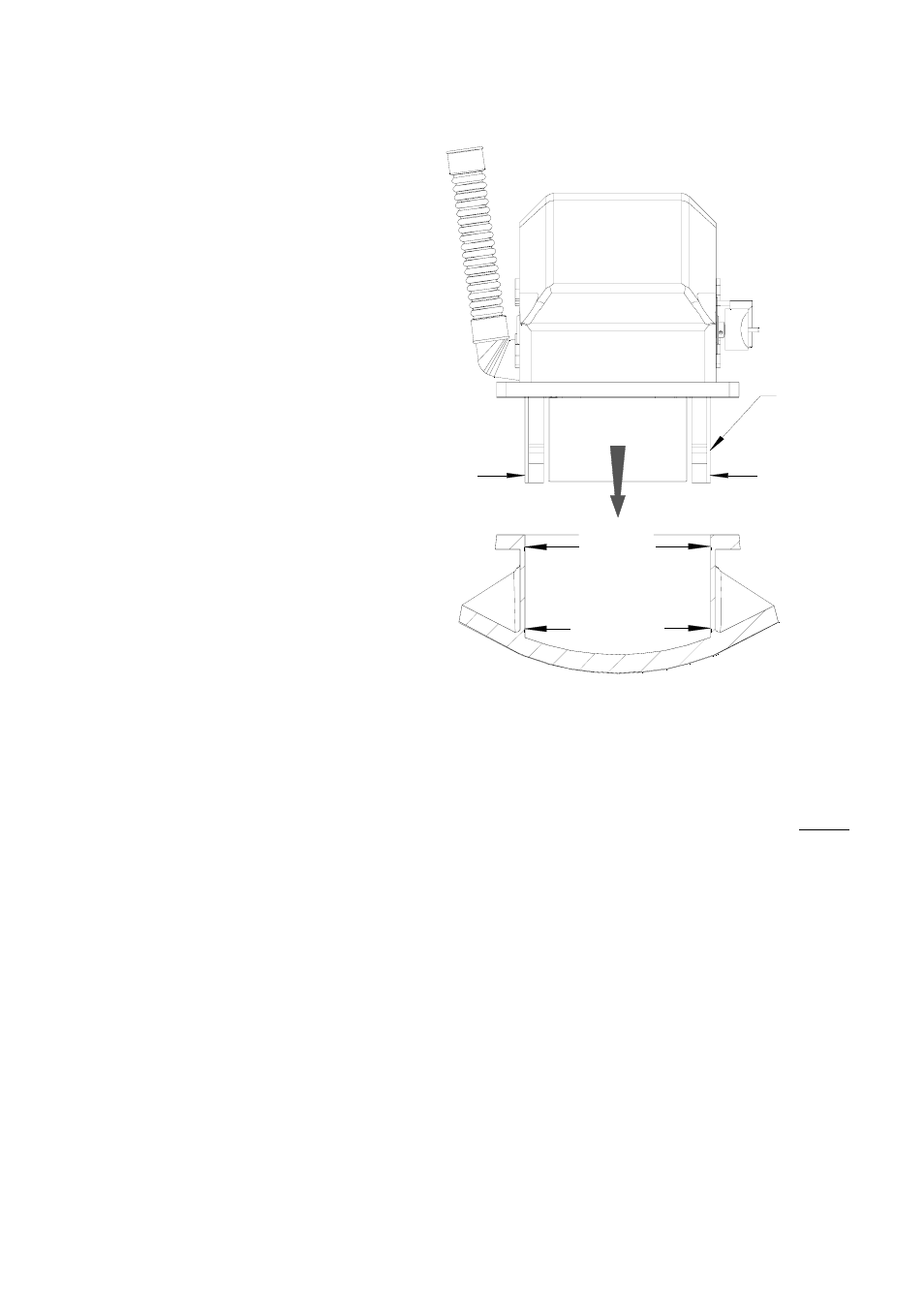

d) The reason for respecting

these dimensions is to avoid

the sliding plates becoming

wedged into mounting base

resulting in the unit getting

stuck in the down position.

e) Before fixing the thruster

unit onto the mounting

base flange it is important to

ensure that the top surface

of the mounting base flange

is perfectly flat to accept the

« O » ring seal of the

Compact Retract base flange

ensuring perfect water

tightness.

3.5

FINAL FITTING OF THE THRUSTER UNIT TO THE MOUNTING BASE

a) Make sure you provide sufficient access underneath the flange to allow for tightening the nuts. If

access is not possible, provide a special mounting flange with metric studs or tapped holes. The

bolts fixing the thruster onto the mounting flange must be inserted from top to bottom, except

for the four bolts on the bow side of the flange, which should be inserted from the bottom to

the top.

b) Final installation of the thruster unit onto the mounting base must be made after thoroughly

cleaning and then liberally coating both joint surfaces (thruster base flange and mounting base

flange) with good quality marine grease, to ensure “O”-ring seal is compressed flat, evenly,

smoothly and squarely when the bolts are tightened.

c) Under no circumstances should the thruster be glued or bedded down with a marine type

mastic/glue such as Sikaflex or other similar product(s).

d) The flange bolts should be tightened sequentially and in successive passes until the two surfaces

touch.

8