Step 5: installing clamps & shims, Do not tighten over 120-inch pounds – Pace-Edwards JR Series Toyota Tundra User Manual

Page 4

JACKRABBIT

®

SERIES 07 TUNDRA

4

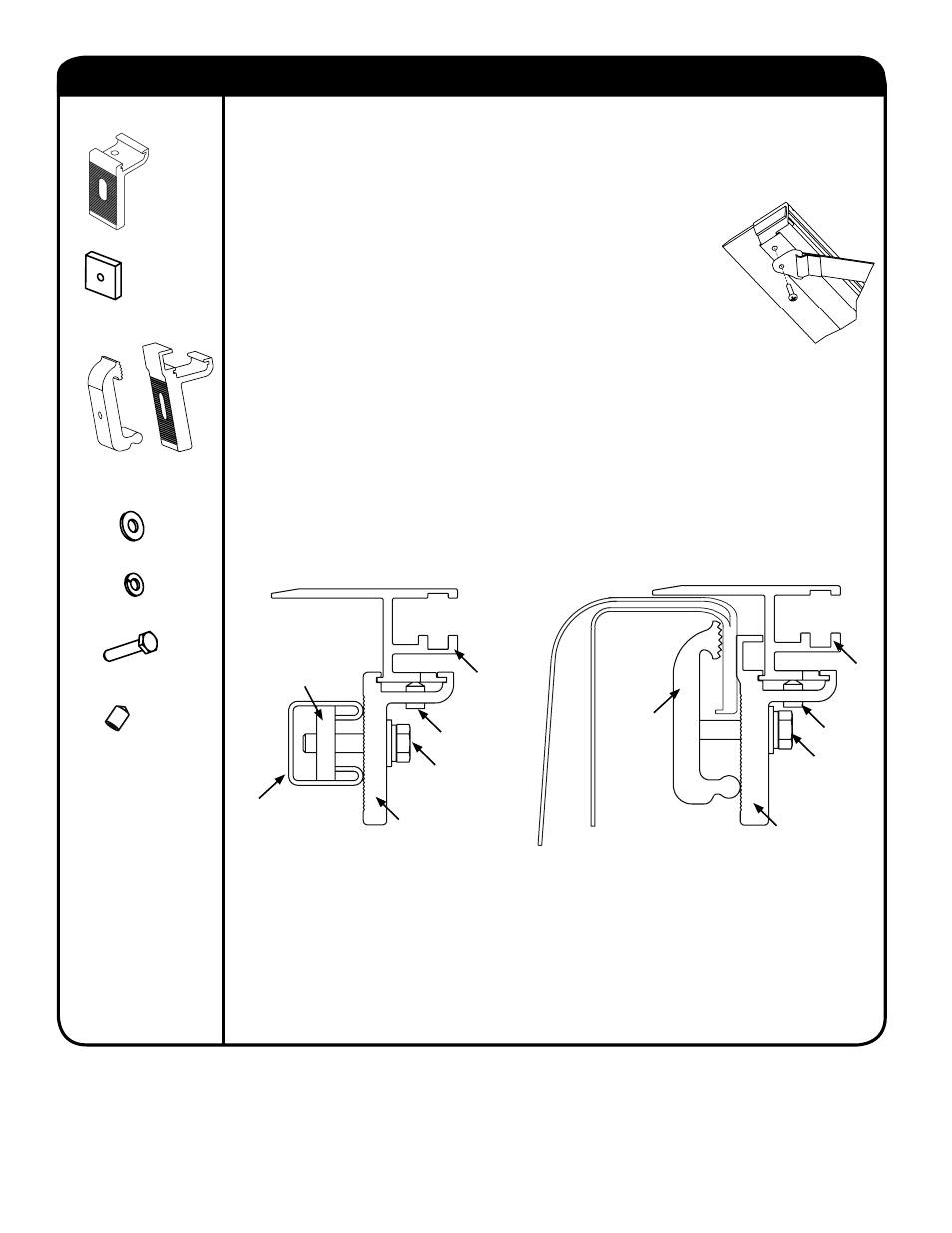

STEP 5: INSTALLING CLAMPS & SHIMS

The Tundra bed is square and the clamps have been designed to fi t without shimming.

Make sure canister is centered between the truck bed rails and completely forward in the bed.

Slide rail grip components onto rail.

Push forward clamp against the canister and rear clamp about 6

inches to a foot from the tailgate.

At this time you must install the tailgate end of the pull strap to the

underside of the drivers side rail using the #8-32 x ¾ machine screw

located at the tailgate end on the underside of the rail. (Fig. 5a) Close

the tailgate and position the rails with a 1/16” gap from the tailgate.

Slide track nuts into the track system and use attachment hardware

(Flat washer, Lock washer & Bolt) to secure clamps in place per FIG

5b. Tighten and secure all the clamps at this time. Install and tighten

the cone point set screws using the 1/8” Allen Wrench.

Measure the distance between the rails at the canister and tailgate ends. Compare this

distance after clamping it should be 58-13/16” to allow your cover to operate properly. A

slightly tighter fi t (but NOT Dragging) is better than a slightly loose fi t.

If the bed does not have the deck rail track system you will use the pinch clamp in place of the

track nut. (Fig 5c)

Once everything is square tighten the Rail clamps completely.

DO NOT TIGHTEN OVER 120-INCH POUNDS!

CLAMP RAIL GRIP x 4

HARDWARE USED:

TRACK NUTS x 4 (used

if truck bed has track

system)

PINCH CLAMP x 4 (used if

truck bed DOES NOT have

the deck rail system track)

1/4” FLAT WASHER x 4

1/4” LOCK WASHER x 4

RAIL CLAMP BOLT x 4

CLAMP RAIL GRIP

TRACK NUT

DECK RAIL

TRACK SYSTEM

HARDWARE

(Flat washer, Lock

washer, & Bolt)

RAIL

PINCH CLAMP

RAIL GRIP

HARDWARE

(Flat washer, Lock

washer, & Bolt)

RAIL

PINCH

CLAMP

(used if the

Deck Rail

System

Track is not

installed)

FIG. 5b

FIG. 5c

CONE SET SCREWS x 4

SET

SCREW

SET

SCREW

FIG. 5a