Step 4: installing rails, Step 5: installing clamps – Pace-Edwards BL Mitsubishi L200 User Manual

Page 4

BEDLOCKER

®

MITSUBISHI L200

4

STEP 4: INSTALLING RAILS

The machined end of the rail attaches to the

canister.

You will need to lift the hanging portion of the

ribbed blanket and thread it in the rail while sliding

the rail into the rail grip mounted to the ends of

the canister (the underside of the blanket ribs

need to nest on the gear).

Make sure both fl anges of rail slide into the rail

grip.

Push the rails forward against the canister.

Complete for both left and right rails.

Remove the support or stand and lower the

canister and rail assembly onto the front sill and

rails of the truck bed.

Slide the entire canister and rail assembly forward

against the cab end of the truck bed.

Close the tailgate and pull the rails only toward it leaving approximately 1/8” gap between the end of the rails and

the tailgate.

Be sure to hold the canister in place to ensure it does not move from the front truck bed sill with the rails while

adjusting the gap of the rails to the tailgate.

Rail Grips

Rail

Flange

Ribbed

Blanket

Before shimming and installing the rail clamps make sure the canister is centered between

the truck bed rails and resting forward against the truck bed sill.

Side rails have a rubber spacer on the end caps, at the tailgate end, to establish the correct

spacing to the tailgate (1/16”) and to prevent the tailgate from striking the side rails when

closing. Press the rails tightly against the closed tailgate.

Shims may be required to maintain a horizontal top surface on the rails.

Peel and stick the shims to the back side of the rail brackets (or the side that will be against

the truck).

Shims are provided in two thicknesses. Shims may need to be stacked on each other to

create the right thickness.

Repeat the same process on each side rail.

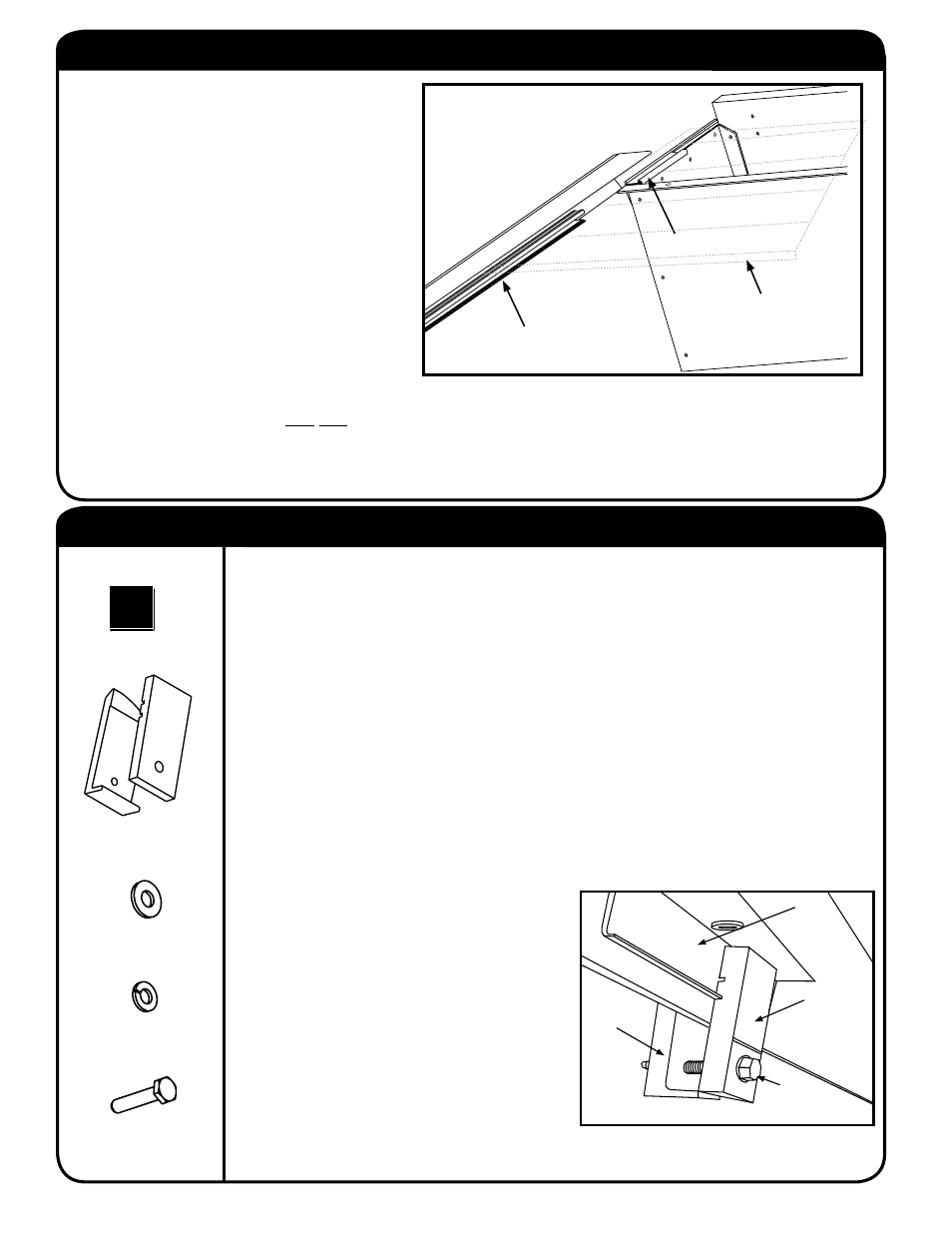

Place the four (4) clamps over the brackets located on the underside of the rails.

Apply downward pressure while tightening the clamps on the rails, especially on the tailgate

end. This will ensure a tight seal, fi rm seat, and good fi t on the truck bed.

Locate the LOWER groove of the inner clamp bracket onto the lip of the rail bracket (as

shown in Figure 6).

Rotate the outer clamp bracket clockwise to

tighten the rail downward against bed rail.

Tighten bolt securely.

(Adjust pressure against tailgate by moving rails

forward or backward as needed prior to fi nal

tightening of clamps.)

Repeat for all clamps.

Ensure that the canister is snug up against the

front sill of the truck bed.

At this time you need to completely tighten the

Canister stop (Installed in Step 3, Fig. 3A) as

well.

The between the rail measurement should be

about 51-13/16” at the front and rear of the rails.

DO NOT TIGHTEN OVER 120-INCH POUNDS!

RAIL

BRACKET

INNER CLAMP

BRACKET

BOLT, FLAT

WASHER &

LOCK WASHER

OUTER CLAMP

BRACKET

FIG. 6

STEP 5: INSTALLING CLAMPS

HARDWARE USED:

OUTER & INNER RAIL

CLAMPS x 4

1/4” FLAT WASHER x 4

1/4” LOCK WASHER x 4

RAIL CLAMP BOLT x 4

PLASTIC SHIMS x 4