Ds1094l multiphase spread-spectrum econoscillator, Typical operating characteristics – Rainbow Electronics DS1094L User Manual

Page 4

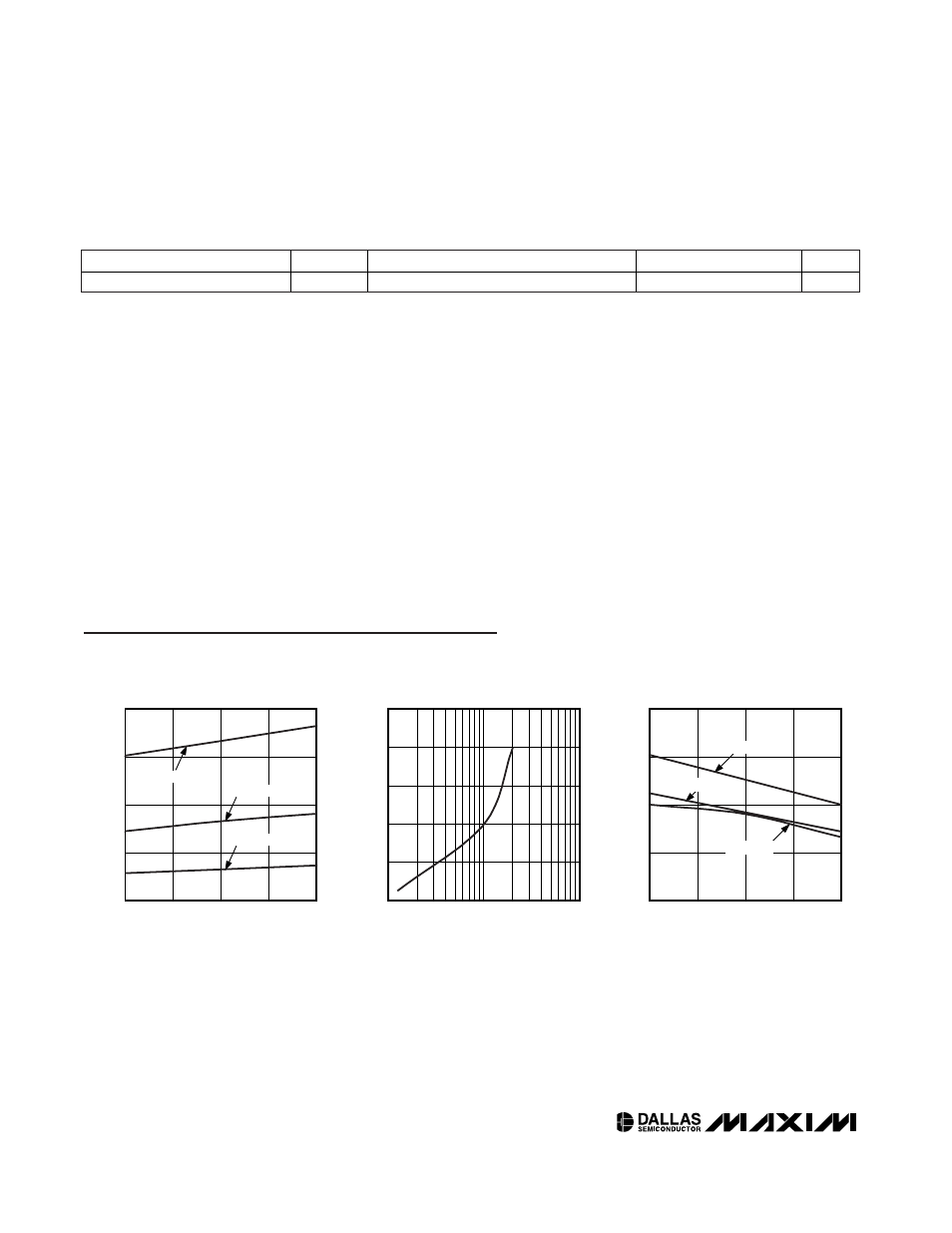

SUPPLY CURRENT vs. SUPPLY VOLTAGE

f

OUT

= 1MHz, 2φ MODE

DS1094L toc01

SUPPLY VOLTAGE (V)

SUPPLY CURRENT (mA)

3.45

3.30

3.15

0.75

1.00

1.25

1.50

0.50

3.00

3.60

T

A

= +85°C

T

A

= +25°C

T

A

= -40°C

SUPPLY CURRENT vs. FREQUENCY

V

CC

= 3.3V, 2φ MODE

DS1094L toc02

fOUT (MHz)

SUPPLY CURRENT (mA)

1.00

0.5

1.5

1.0

2.0

2.5

0

0.1

10.00

DUTY CYCLE vs. SUPPLY VOLTAGE

f

OUT

= 2MHz, 2φ MODE

DS1094L toc03

SUPPLY VOLTAGE (V)

DUTY CYCLE (%)

3.45

3.30

3.15

50.25

50.50

50.75

51.00

50.00

3.00

3.60

T

A

= +85°C

T

A

= +25°C

T

A

= -40°C

Typical Operating Characteristics

(V

CC

= +3.3V, T

A

= +25°C, unless otherwise noted.)

DS1094L

Multiphase Spread-Spectrum EconOscillator

4

_____________________________________________________________________

NONVOLATILE MEMORY CHARACTERISTICS

(VCC = +3.0V to 3.6V, unless otherwise noted.)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

EEPROM Writes

+70°C (Note 4)

10,000

Note 1: All voltages referenced to ground.

Note 2: This is the change observed in output frequency due to changes in temperature or voltage.

Note 3: This is a percentage of the output period. Parameter is characterized but not production tested. This can be varied from

2%, 4%, or 8%.

Note 4: This parameter is guaranteed by design.

Note 5: This indicates the time between power-up and the outputs becoming active. An on-chip delay is intentionally introduced to

allow the oscillator to stabilize. t

STAB

is equivalent to approximately 64 f

MOSC

cycles and, hence, will depend on the pro-

grammed clock frequency.

Note 6: Timing shown is for fast-mode (400kHz) operation. This device is also backward compatible with I

2

C standard-mode timing.

Note 7: CB—total capacitance of one bus line in picofarads.

Note 8: Typical frequency shift due to aging is ±0.5%. Aging stressing includes Level 1 moisture reflow preconditioning (24hr

+125°C bake, 168hr 85°C/85%RH moisture soak, and 3 solder reflow passes +240 +0/-5°C peak) followed by 1000hr max

V

CC

biased 125°C HTOL, 1000 temperature cycles at -55°C to +125°C, and 168hr 121°C/2 ATM Steam/Unbiased Autoclave.