Rainbow Electronics MAX6616 User Manual

Page 8

MAX6615/MAX6616

ture. The thermistor data in the temperature register(s)

gives the voltage across R

EXT

as a fraction of the refer-

ence voltage. The LSB of the high byte has a nominal

weight of 7.68mV.

O

OT

T

Output

The OT output asserts when a thermal fault occurs, and

can therefore be used as a warning flag to initiate sys-

tem shutdown, or to throttle clock frequency. When

temperature exceeds the OT temperature threshold

and OT is not masked, the OT status register indicates

a fault and OT output becomes asserted. If OT for the

respective channel is masked off, the OT status register

continues to be set, but the OT output does not

become asserted.

The fault flag and the output can be cleared by reading

the OT status register. The OT output can also be

cleared by masking the affected channel. If the OT sta-

tus bit is cleared, OT reasserts on the next conversion if

the temperature still exceeds the OT temperature

threshold.

PWM Output

The PWM_ signals are normally used in one of three

ways to control the fan’s speed:

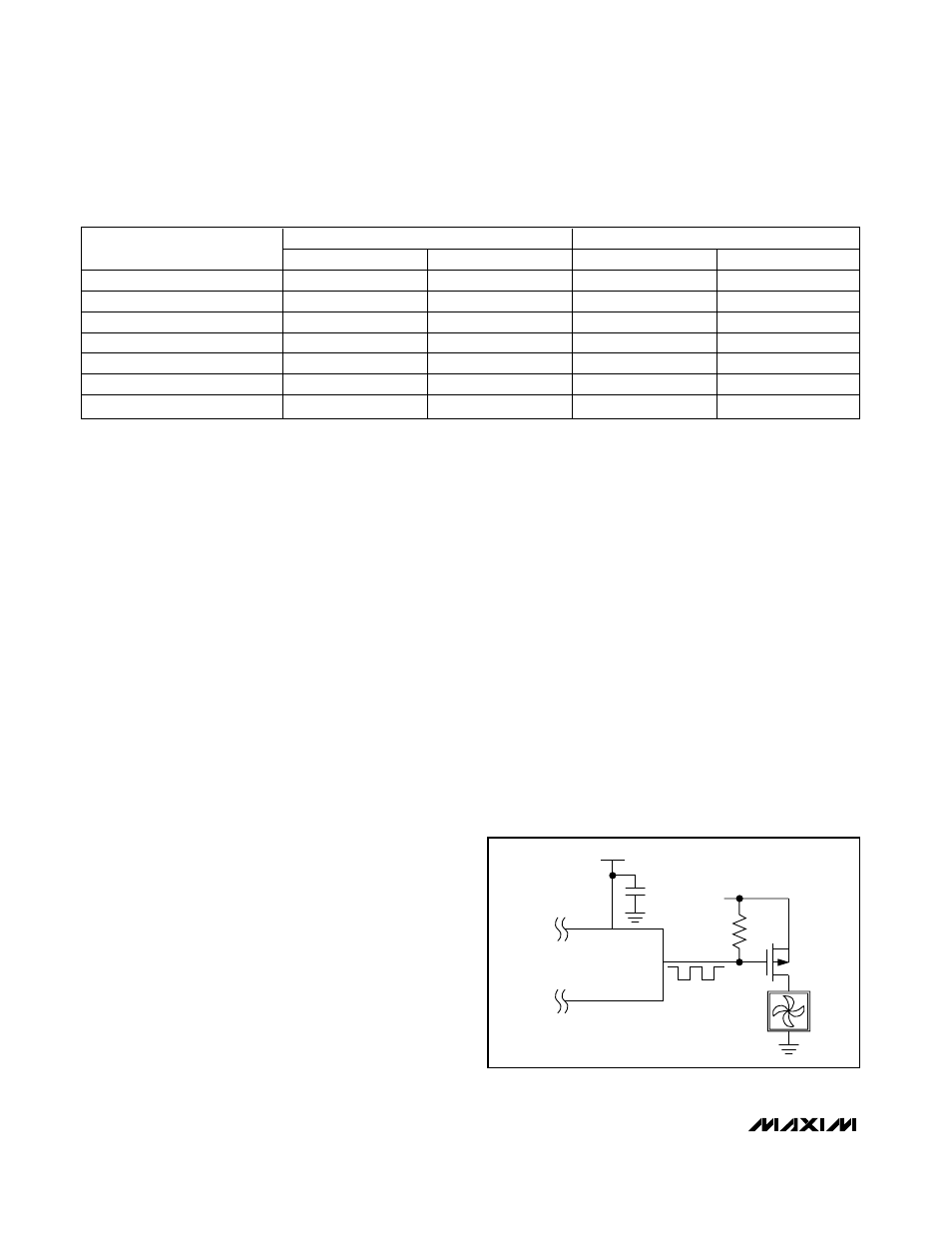

1) PWM_ drives the gate of a MOSFET or the base of a

bipolar transistor in series with the fan’s power sup-

ply. The Typical Application Circuit shows the PWM_

driving an n-channel MOSFET. In this case, the PWM

invert bit (D4 in register 02h) is set to 1.

Figure 4

shows PWM_ driving a p-channel MOSFET and the

PWM invert bit must be set to zero.

2) PWM_ is converted (using an external circuit) into a

DC voltage that is proportional to duty cycle. This

duty-cycle-controlled voltage becomes the power

supply for the fan. This approach is less efficient

than (1), but can result in quieter fan operation.

Figure 5 shows an example of a circuit that converts

the PWM signal to a DC voltage. Because this circuit

produces a full-scale output voltage when PWM =

0V, bit D4 in register 02h should be set to zero.

3) PWM_ directly drives the logic-level PWM speed-

control input on a fan that has this type of input. This

approach requires fewer external components and

combines the efficiency of (1) with the low noise of

(2). An example of PWM_ driving a fan with a speed-

control input is shown in Figure 6. Bit D4 in register

02h should be set to 1 when this configuration is

used.

Whenever the fan has to start turning from a motionless

state, PWM_ is forced high for 2s. After this spin-up

period, the PWM_ duty cycle settles to the predeter-

mined value. Whenever spin-up is disabled (bit 2 in the

configuration byte = 1) and the fan is off, the duty cycle

changes immediately from zero to the nominal value,

ignoring the duty-cycle rate-of-change setting.

The frequency-select register controls the frequency of

the PWM signal. When the PWM signal modulates the

power supply of the fan, a low PWM frequency (usually

33Hz) should be used to ensure the circuitry of the

Dual-Channel Temperature Monitors and

Fan-Speed Controllers with Thermistor Inputs

8

____________________________________________________

Table 1. Temperature Data Format (High Byte and Low Byte)

HIGH BYTE

LOW BYTE

TEMPERATURE (°C)

BINARY VALUE

HEX VALUE

BINARY VALUE

HEX VALUE

140.0

1000 1100

8Ch

0000 0000

00h

127.0

0111 1111

7Fh

0000 0000

00h

25.375

0001 1001

19h

0110 0000

60h

25.0

0001 1001

19h

0000 0000

00h

0.5

0000 0000

00h

1000 0000

80h

0.0

0000 0000

00h

0000 0000

00h

<0

0000 0000

00h

0000 0000

00h

V

CC

PWM

10k

Ω

5V

P

Figure 4. Driving a p-Channel MOSFET for Top-Side PWM Fan

Drive