Assembly instructions (continued) – Wilwood W4A Big Brake Truck Rear Brake Kit User Manual

Page 4

• With the larger I.D. side of the rotor (3) facing away from the hat (4), bolt rotor (3) to hat (4)

through the backside of the rotor using washers (5) and bolts (6). Using an alternating

sequence, apply red Loctite® 271 to the threads and torque bolts to 140 in-lb. For an added

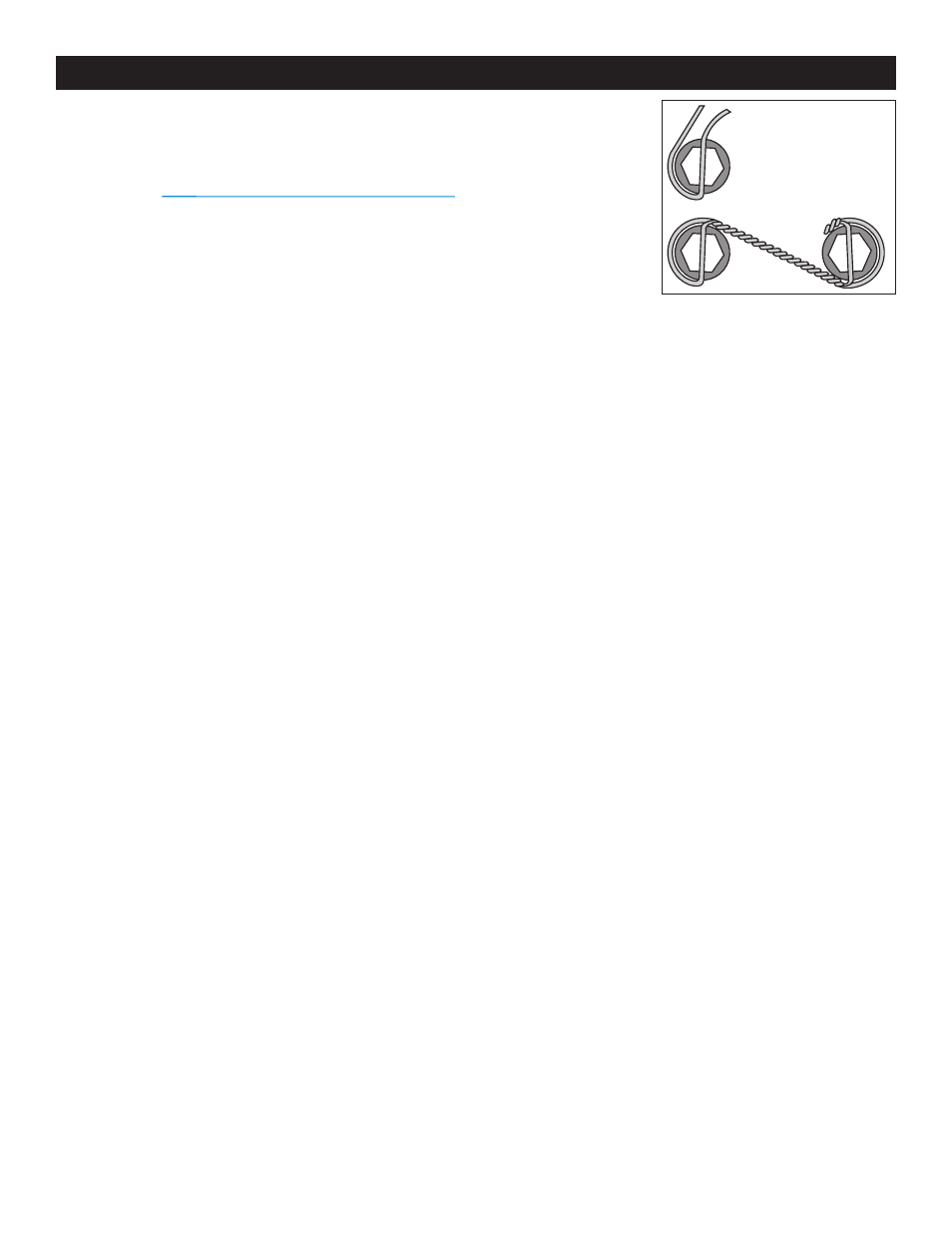

measure of security, the bolts may be safety wired using standard 0.032 inch diameter

stainless steel safety wire as shown in Figure 3. Please refer to Wilwood’s data sheet DS-386

(available at

www.wilwood.com/Pdf/DataSheets/ds386.pdf

) for complete safety wire

installation instructions.

• Install the hat and rotor assembly onto the hub. Check to be sure the hat seats squarely

against the hub. The hub must be free from any rust, debris, casting burrs, machining

irregularities, etc. Use several lug nuts to hold the rotor and hat firmly against the hub during

the next phases of the installation and clearance checking procedures.

• Install one shim (11) over each stud (10) on the radial mount bracket (1). Slide the caliper (7)

in place over the studs and rotor and install the washer (9) and lock nut (8) to hold the caliper

in place. The caliper bleed screws should be pointing up. Snug the lock nuts (8) and check

that the rotor (3) is centered in the caliper (7). Add or subtract .029" shims (2) as necessary

between the caliper mount bracket (1) and the caliper mount bosses on the upright assembly

to center the caliper (7).

• Remove the two caliper pad retaining pins from the caliper (1) by popping out the pin retaining clips and sliding out the pins. Slide the

brake pads (12) into place. They should install easily without interference. Check that the outside radius of the brake pad is aligned

with the outside diameter radius of the rotor face. Add or subtract shims (11) between the caliper and mount bracket to gain the proper

alignment. Reinstall the pad retaining pins and secure using the pin retaining clips.

• Adjust the parking brake shoes outward (using a drum shoe adjustment tool available at your local auto parts store) while spinning the

hat (4) until a slight drag is felt against the hat/drum.

• Remove the lug nuts that were holding the hat/rotor in place. Install the wheel and torque the lug nuts to manufacturer’s specification.

Check to see that the wheel rotates freely without interference.

• Once all clearances have been checked, remove the wheel, caliper and rotor from the axle flange. Secure the caliper mounting bracket

(1) to the upright using red Loctite

®

271 on the bolt threads. Torque the bolts to manufacturer’s specifications. Reinstall the rotor and

again use several lug nuts to hold it in place. Lubricate caliper mounting studs and nuts with lightweight oil, reinstall the caliper,

torque the caliper nuts (8) to 47 ft-lbs.

•NOTE: OEM rubber brake hoses generally cannot be adapted to Wilwood calipers. The caliper inlet fitting is a 1/8-27 NPT. The preferred

method is to use steel adapter fittings at the caliper, either straight, 45 or 90 degree and enough steel braided line to allow for full

suspension travel and turning radius, lock to lock. Carefully route lines to prevent contact with moving suspension, brake or wheel

components. Wilwood hose kits are designed for use in many different vehicle applications and it is the installer's responsibility to

properly route and ensure adequate clearance and retention for brake hose components. Wilwood offers a hose kit, P/N 220-8999

(1999-2006) and P/N 220-11196 (2007-2011), which includes hoses, fittings, etc., all in one package for this application.

•Specified brake hose kits may not work with all Years, Makes and Models of vehicle that this brake kit is applicable to, due to possible

OEM manufacturing changes during a production vehicle's life. It is the installer's responsibility to ensure that all fittings and hoses are

the correct size and length, to ensure proper sealing and that they will not be subject to crimping, strain and abrasion from vibration or

interference with suspension components, brake rotor or wheel.

•In absence of specific instructions for brake line routing, the installer must use his best professional judgment on correct routing and

retention of lines to ensure safe operation. Test vehicle brake system per the 'minimum test' procedure stated within this document

before driving. After road testing, inspect for leaks and interference. Initially after install and testing, perform frequent checks of the

vehicle brake system and lines before driving, to confirm that there is no undue wear or interference not apparent from the initial test.

Afterwards, perform periodic inspections for function, leaks and wear in a interval relative to the usage of vehicle.

•Repeat this entire procedure for the other wheel.

• Bleed the brake system. Reference the general information and recommendations on page 5 for proper bleeding instructions.

• Remove the lug nuts that were used to hold the hat/rotor assembly in place during caliper installation. Install the wheel and torque the

lug nuts to OEM specifications.

Assembly Instructions (Continued)

BEGIN BY SLIDING THE 0.032"

DIAMETER WIRE THROUGH TWO OF

THE HOLES (LEFT) THAT ARE 180°

APART. TWIST THE WIRE AS

SHOWN (BELOW) USING SAFETY

WIRE PLIERS. NOW SLIDE ONE

WIRE THROUGH TWO OF THE

HOLES (180° APART) AND WRAP THE

OTHER WIRE AROUND THE BOLT.

TWIST THE WIRES TOGETHER TO

FORM A PIGTAIL. SEE DS-386 FOR

COMPLETE DETAILS.

Figure 3. Safety Wire Diagram

Page 4