Grain Systems Tanks PNEG-4075G User Manual

Page 166

1. Install a wind ring bracket (B) to each stiffener (C) using flange bolts (A) and flange nuts (D).

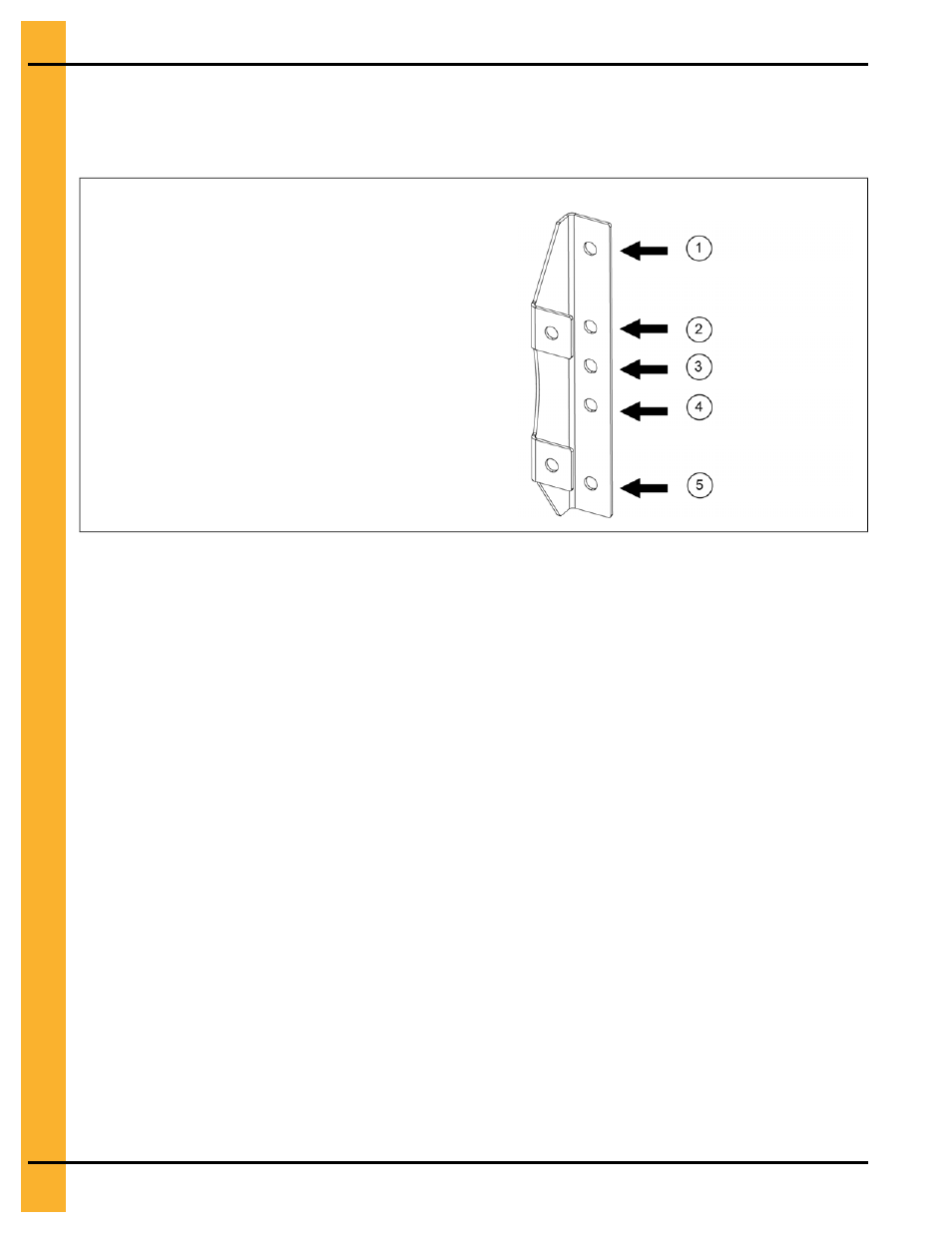

Figure 8-30 Wind ring bracket

NOTE: When installing the wind ring bracket to a

2.66" close punched stiffener, use the bolt

holes marked 1, 2, 4, and 5 as shown.

When installing the wind ring bracket to a

2.66" far punched stiffener, use the bolt

holes marked 1 and 5 only. Hole marked 3

will not be used on all 2.66" bins. Flange

bolt hardware length may vary with side-

wall gauge thickness.

2. Tighten hardware to the recommended torque specifications. See

Bolt Torque Specifications, page

.

3. Place a wind ring section (E) into the channel of the wind ring bracket (B), and install a C-clamp (I),

securing with flange bolts (H) and flange nuts (J). Do not tighten until all wind ring sections are

installed.

4. Repeat this procedure, inserting each wind ring section (E), over the previously installed wind ring

section, securing the wind ring sections together with flange bolts (F) and hex nuts (G).

5. Before installing the last wind ring section (E), slide a wind ring coupling collar (K) over the wind ring

section (E).

6. Install the last wind ring section (E) and cut the wind ring section to the proper length.

NOTE: The cut needs to be made in a location that allows minimal space between the pipes.

7. Slide the wind ring coupling collar (K), aligning the three pre-drilled holes, and install flange bolts (F)

and hex nuts (G). Field drill the remaining three holes (L) using the wind ring coupling collar (K) as a

guide or template.

8. Install the remaining flange bolts (F) and hex nuts (G), and tighten all hardware to the recommended

torque specifications. See

Bolt Torque Specifications, page 24

.

166

Pneg-4075G 75 Ft Diameter 40-Series Bin