Chapter 8: accessories – Grain Systems Tanks PNEG-4075G User Manual

Page 156

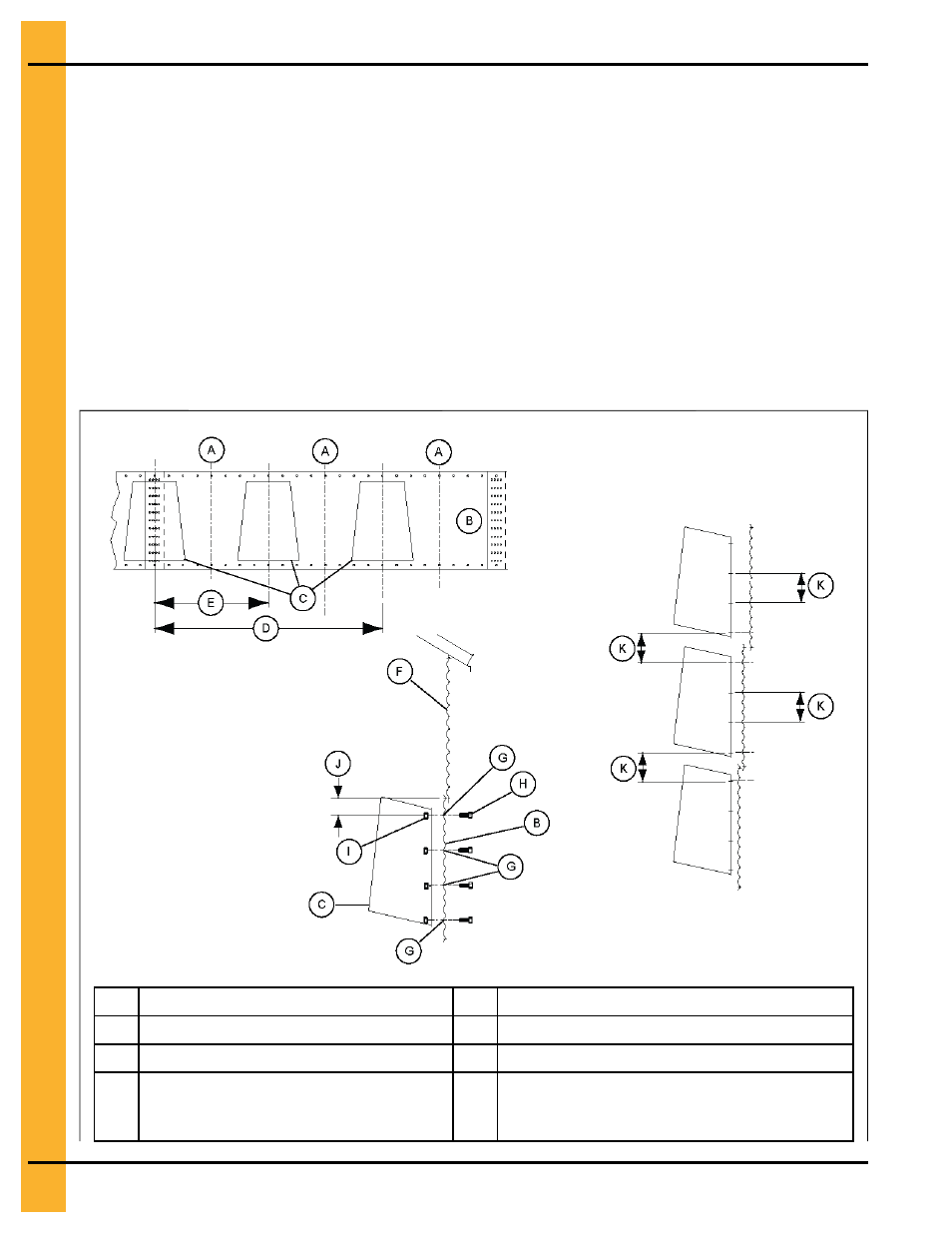

NOTE: Depending on the location of the baffle chute (C), the measurement from the sidewall edge

will vary (D or E).

3. Locate the horizontal seam connecting the first and second ring, and measure approximately 2-21/32

in. (J) from the center hole in the horizontal seam, to the first center hole on the baffle chute, mark or

scribe the hole location.

4. Align and the first baffle chute hole with the mark or scribe, and ensure the baffle chute is level. Place

another mark or scribe at the opposite hole on the baffle chute (C).

5. Field drill a 7/16 in. hole and install flange bolts (H) and flange nuts (I).

6. Repeat the field drilling process for the remaining six holes.

7. Repeat this procedure for the remaining baffle chutes.

NOTE: A typical installation has equal spacing (K).

Figure 8-21 First chute locations (three post stiffener only), and spacing of each baffle chute

A

Stiffener’s center line

G

Field drilled hole location (7/16 in. diameter hole)

B

Second ring from top of bin

H

3/8 x 1-1/2 in. flange bolt (S-7488)

C

Suitable baffle chute locations

I

3/8 in. flange nut (S-456)

D

Measurement from edge of sidewall sheet

to center line of baffle chute, 37-1/2 in.

(95.25 cm.)

J

Measurement, approximately 2-21/32 in. (6.77

cm.)

156

Pneg-4075G 75 Ft Diameter 40-Series Bin