Drive motor and motor mount, Chapter 11 drive motor and motor mount, Drive motor mount assembly – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-681 User Manual

Page 26: Drive, Motor mount assembly

26

PNEG-681 Series II Bucket Elevator

11. Drive Motor and Motor Mount

Drive

The following assembly instructions are for standard drives as purchased with the elevator. The standard

drive is designed using the Dodge Torque Arm II shaft mount reducer. Details for this application are

included in the appendix section

If you purchased a special drive or drive components from another source, refer to manuals supplied with

these materials.

1. The drive assembly is designed so that the same components fit a left or right hand drive application.

2. If facing the head side, the reducer is between you and the head and the head discharge is on the

right hand side of you, then you have a right hand drive application.

3. If the head discharge is on the left side of you, then you have a left hand drive application.

shown for a right hand application.

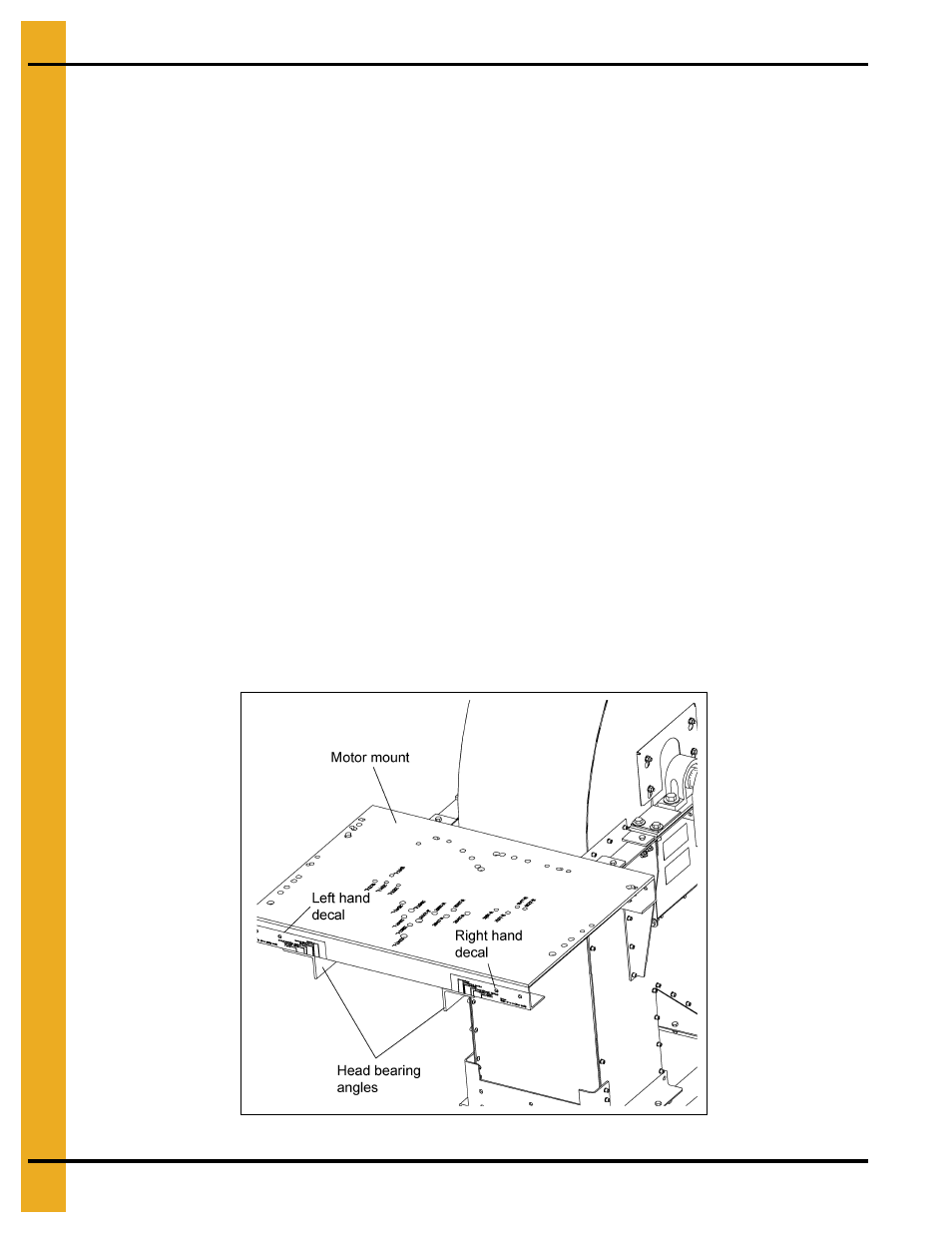

Motor Mount Assembly

1. Locate the side of the motor mount which has two (2) decals affixed.

One decal

will have “L.H.” for left hand and one will have “R.H.” for right hand.

2. Place the motor mount with decals facing away from the pulley towards the end of the head

bearing angles.

3. Note the horsepower, class rating and drive application side on the decals. Follow the indication line

next to those numbers to where it points down to the bottom of the motor mount.

4. Slide the motor mount in or out while keeping the decal correctly aligned with the outside toe of the

head bearing angle.

This will align the holes in the head bearing angles

to the proper holes in the motor mount assembly.

5. Using the proper hardware, bolt the motor mount down to the head bearing angles.

Figure 11A Motor Mount Plate