General installation practices – Banks Power Ford Trucks: (Diesel ’83 - 93 6.9 & 7.3L) Forced Induction- Sidewinder turbo system (Van) 6.9 & 7.3L User Manual

Page 5

5

geneRaL InstaLLatIOn pRactIces

1.

For ease of installation and trouble-free

operation of your BanKs turbocharger

system, pLease Read tHIs entIRe 24-page

InstRuctIOn pacKage BefORe staRtIng anY

WORK. If any pages are missing from this package,

please call gALE bAN kS EN gINEERIN g

immediately for a replacement.)

Become thoroughly familiar with all components

and phases of the installation. Determine what

additional tools or materials you may need to

complete the installation, and at what stages you

will require welding, if it is to be done by other

than yourself.

2.

Inspect all components supplied for any

foreign material that may have entered

during shipping and handling. Wash all fuel and oil

hoses with solvent and blow dry with compressed

air before assembly. Inspect all castings for

damage resulting from shipping. check all

machined surfaces for nicks or other damage.

clean all castings with solvent and blow dry with

compressed air prior to assembly.

3.

any time the vehicle is raised off its wheels,

it should be supported by jack stands or

ramps of adequate capacity for the vehicle’s

weight. neveR peRfORM anY WORK undeR a

veHIcLe suppORted OnLY BY Its BuMpeR OR

HYdRauLIc JacK.

4.

use the teflon tape provided on all pipe

thread connections. hold tape back from

the first two threads of the fitting so tape will not

flake off into the fluid. (this is especially critical on

oil lines.)

5.

All threads to be secured with Loctite must

be clean, dry and free of any oil or grease.

clean threads with lacquer thinner as required.

6.

pay particular attention to the routing of all

hoses and wiring. Keep them away from

exhaust heat, moving parts and sharp edges that

may cause cuts or other damage. Route or tie

hoses away from critical areas as required. Keep

all hoses a minimum of 1” from hot exhaust parts;

1

1

⁄

2

” or more is recommended whenever possible.

7.

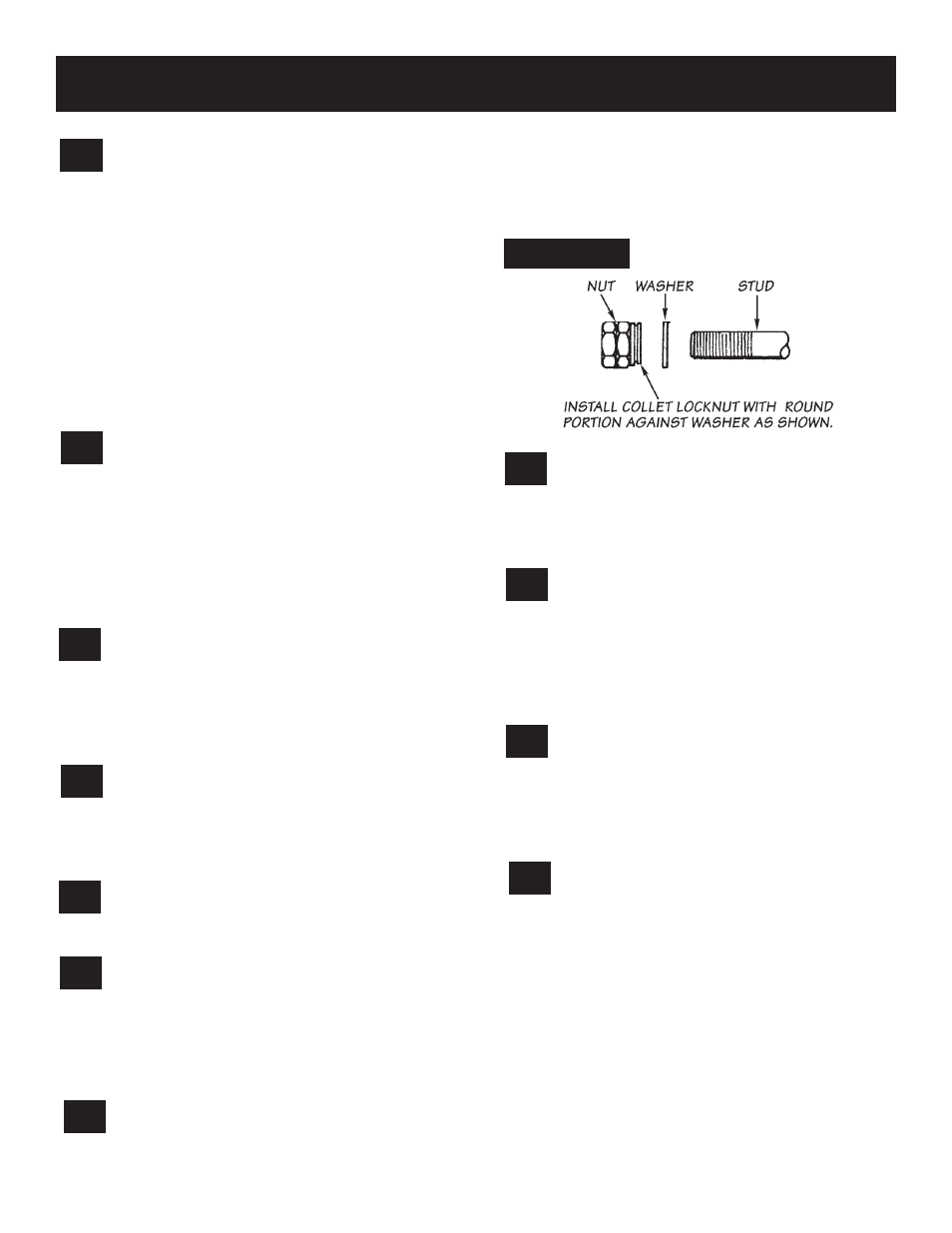

collet stainless steel locknuts are used on

the studs in the turbine mounting bracket.

the locknuts should be installed as shown in

figure 3

. the nuts will spin on freely and lock only

when tightened.

8.

Muffler and exhaust piping are not included

with this kit. an exhaust parts kit containing

these components is available separately from

gaLe BanKs engIneeRIng. the BanKs 3” exhaust

system is required for emissions legal installation.

9.

general assembly diagrams are provided in

addition to the specific step or section

diagrams in the text. general assembly diagrams

show relationships of individual components for

reference; however, numbered step-by-step

procedures should be followed for proper

assembly sequence.

10.

Right-hand and left-hand designations refer

to the driver’s right or left, as seated in the

vehicle, (i.e.: Right-hand refers to the passenger

side of the vehicle, unless noted otherwise. “fWd”

in illustrations refers to “fORWaRd”, or “fROnt

Of veHIcLe”.

11.

aLL BanKs components are designed,

tested and manufactured to standards far

exceeding factory OeM specifications. However,

due to normal variations in production vehicles, it

may be necessary to slightly modify some

exhaust-system components for proper fit.

NOtE: All parts are furnished in kit unless noted

otherwise.

Notification:

The Banks Ram-Air Filter comes pre-

oiled and no piling is necessary for

initial installation. Service the Filter

as specified in the Cleaning and Oiling

the Banks Ram-Air Filter Section of this

manual.

FIguRE 3

P.N. 96308 V.2.0