Banks Power Universal Car & Truck: (Gas or Diesel ’50 - 14 Universal) Water-Methanol: Straight-Shot and Double Shot, Vehicle specific applications User Manual

Page 20

20

97651 v.1.0

4c.

If there is debris present in the con-

tainer after running the initial test, re-fill

the system tank with clean distilled water

and repeat “TEST” mode until all debris

remaining from installation has been

purged from the system. Check all tubing

connections for leaks.

: If the controller dis-

plays an error code, or the pump

does not turn on when activating

“TEST” mode, refer to the error code

index (page 27) and use system

schematic (P/N 97650-A or 97651-

A) to ensure all components were

connected to appropriate connec-

tors. Check all connectors for full

engagement. If pump turns on, but

water does not flow out of tubing,

use system schematic (P/N 97650-A

or 97651-A) to ensure system was

plumbed correctly.

4d.

Remove all injector nozzle(s) from

their mounting ports on the engine and re-

connect them to their supply tubes. Empty

water from the clear container used in

the previous step, insert the assembled

injector nozzles and supply lines back into

the container and re-secure in a stable

position.

4e.

Initiate another “TEST” mode from

the injection controller and examine the

spray pattern from each nozzle. A clean,

evenly-distributed spray cone should be

visible from every nozzle (some moderate

pulsation is normal and will vary based on

nozzle selection). Examine the threaded

joint between each nozzle and nozzle

holder carefully for any leaks during this

high pressure test - tighten the assembly

in quarter turn steps until corrected.

4e.

Dribbling or spitting from one or

more nozzles while other nozzles atomize

properly indicates a partially plugged nozzle

or filter - exit “TEST” mode, remove the

nozzle from the holder fitting. Use pliers to

unscrew screen holder and examine the

screen for debris.

4g

. If no leaks are noted

and each nozzle is atomizing correctly,

exit “TEST” mode and turn off the vehicle’s

ignition switch to power down the injec-

tion controller.

5.

Double-check tubing and all connec-

tions for leaks. Permanently install injec-

tion nozzles and tubing into appropriate

locations, and reconnect pump pressure

switch.

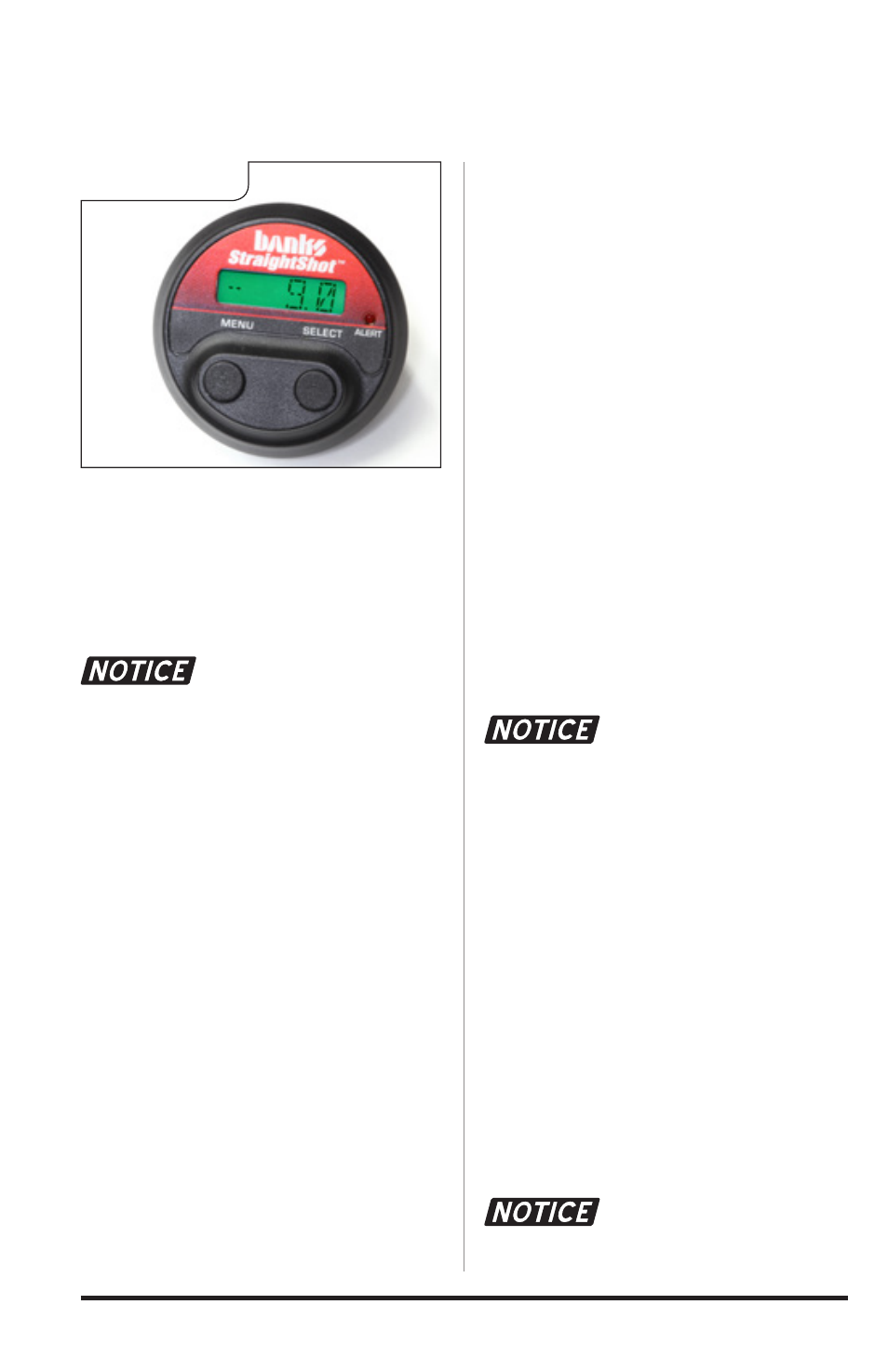

: To setup the Straight-

Shot injection controller for first-

time use, several selections needs

to be made for the controller to con-

figure it for your specific application.

6.

Turn vehicle ignition to on without

starting the vehicle. Select the “INPT”

(input) sub-menu using “MENU” button to

scroll through main menu and “SELECT”

button to select “INPT”. Scroll through the

“INPT” menu and select “MAP” (Manifold

Absolute Pressure) for boosted applica-

tions or “THRT” (throttle) for non-boosted

applications. “MAP” is the default input

method, and requires that a specific MAP

sensor type be selected (in the following

step). If “THRT” mode is selected, no fur-

ther input configuration is required - the

controller will display throttle value from

0-100% based on a 0.5V-4.5V range.

: Main menu, “OCTL”

submenu, and “DISP” sub-menu

will display different options based

Figure 44