Plumbing (straight-shot) – Banks Power Universal Car & Truck: (Gas or Diesel ’50 - 14 Universal) Water-Methanol: Straight-Shot and Double Shot, Vehicle specific applications User Manual

Page 12

12

97651 v.1.0

6.

Thread Injection Nozzle assembly into

the air intake duct. Cover open end of the

90-degree Push-Lock fitting to avoid debris

entering intake duct. See Figure 27

Plumbing (Straight-Shot)

: If you purchased the

Double-Shot system proceed to the

Plumbing (Double-Shot) section.

: Route and secure

tubing where it will not interfere

with moving or hot engine compo-

nents. Avoid sharp turns that may

kink tubing and sharp edges that

may damage tubing.

: Cut tubing using

a Pocket or X-Acto knife to avoid

pinching the tubing. Pinching the

tubing will cause it to not seat

properly.

1.

Secure one end of 1/4” Nylon tub-

ing (P/N 45140) into Push-Lock fitting on

windshield washer fluid reservoir by firmly

pushing tubing into Push-Lock fitting.

Carefully pull on tubing to ensure tubing is

secured properly.

2.

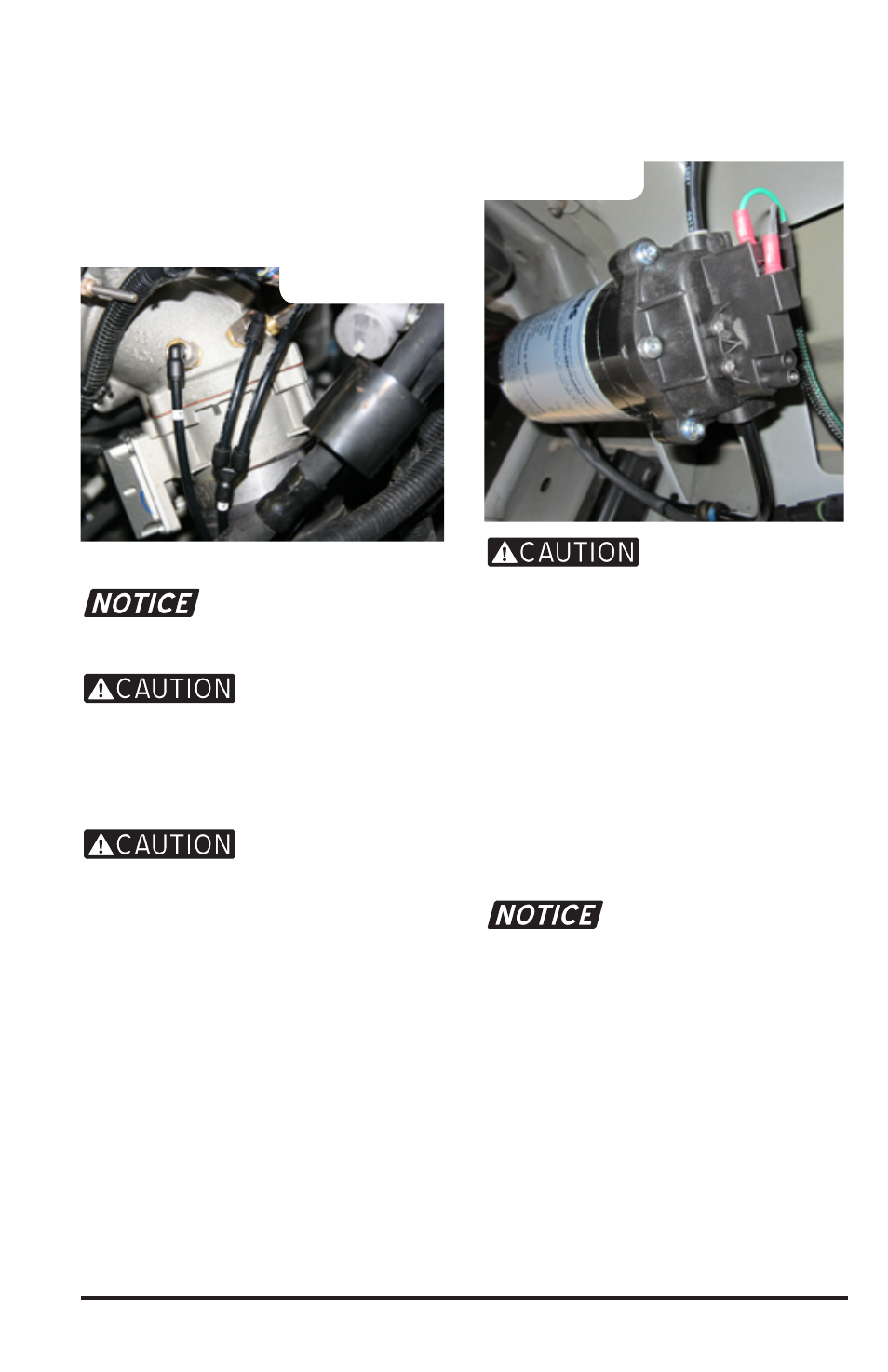

Route tubing to injection pump inlet.

Cut tubing, allowing approximately 1/2”

for securing into injection pump. Properly

secure tubing into injection pump inlet.

See Figure 28

: Make all cuts as

square as possible to avoid leaks.

3.

For a single injection nozzle, secure

and route tubing from pump outlet to

injection nozzle assembly in intake duct.

Properly cut tubing and secure into injec-

tion nozzle assembly.

4.

For two injection nozzles, secure and

route tubing from pump outlet to port

#1 of “Y” fitting (P/N 45123). Properly

cut tubing and secure into “Y” fitting.

See Figure 29

: Determine where you

want Push-Lock “Y” fitting located and

route tubing appropriately. Choose a

location that is easily accessible and

can be checked for leaks.

4a.

Secure tubing in port #2 of “Y” fitting

and route tubing to first injection nozzle

assembly. Properly cut tubing and secure

into injection nozzle assembly.

4b.

Repeat step 4a for second injection

nozzle assembly using port #3 on the

“Y” fitting.

5.

Use tie wraps to secure all tubing.

Figure 28

Figure 27