Figure 16 figure 15 – Banks Power GM Motorhomes: (Gas ’82 - 95 7.4L) PowerPack system (Carbureted, dual air pump) User Manual

Page 11

Open a number 56 hose clamp and thread it

through to slots on the oil filter heat shield.

See Figure

14

. Position the heat shield on the oil

filter to provide protection from the closest mani-

fold pipe, then tighten clamp.

Install an exhaust “doughnut” seal in the

right exhaust manifold outlet flange. Lightly

tap the seal into place with a hammer until it

seats.

install three

3

⁄

8

” x 2

1

⁄

4

” studs in the right

exhaust manifold outlet flange. Two

3

⁄

8

coarse thread nuts jammed against each other on

the outer stud threads may be used to wrench the

studs into place. use anti-sieze compound on the

threads.

install three

3

⁄

8

” x 2

7

⁄

8

” studs in the left

exhaust manifold outlet flange. use anti-

sieze compound on the threads.

Remove the old “doughnut” seal from the

heat riser valve (ePR) if still attached, and

replace with new seal provided. Lightly tap the

seal into place to seat it.

slide the heat riser valve into position on

the studs of the left exhaust manifold out-

let. note that the actuating diaphragm faces up

and to the left.

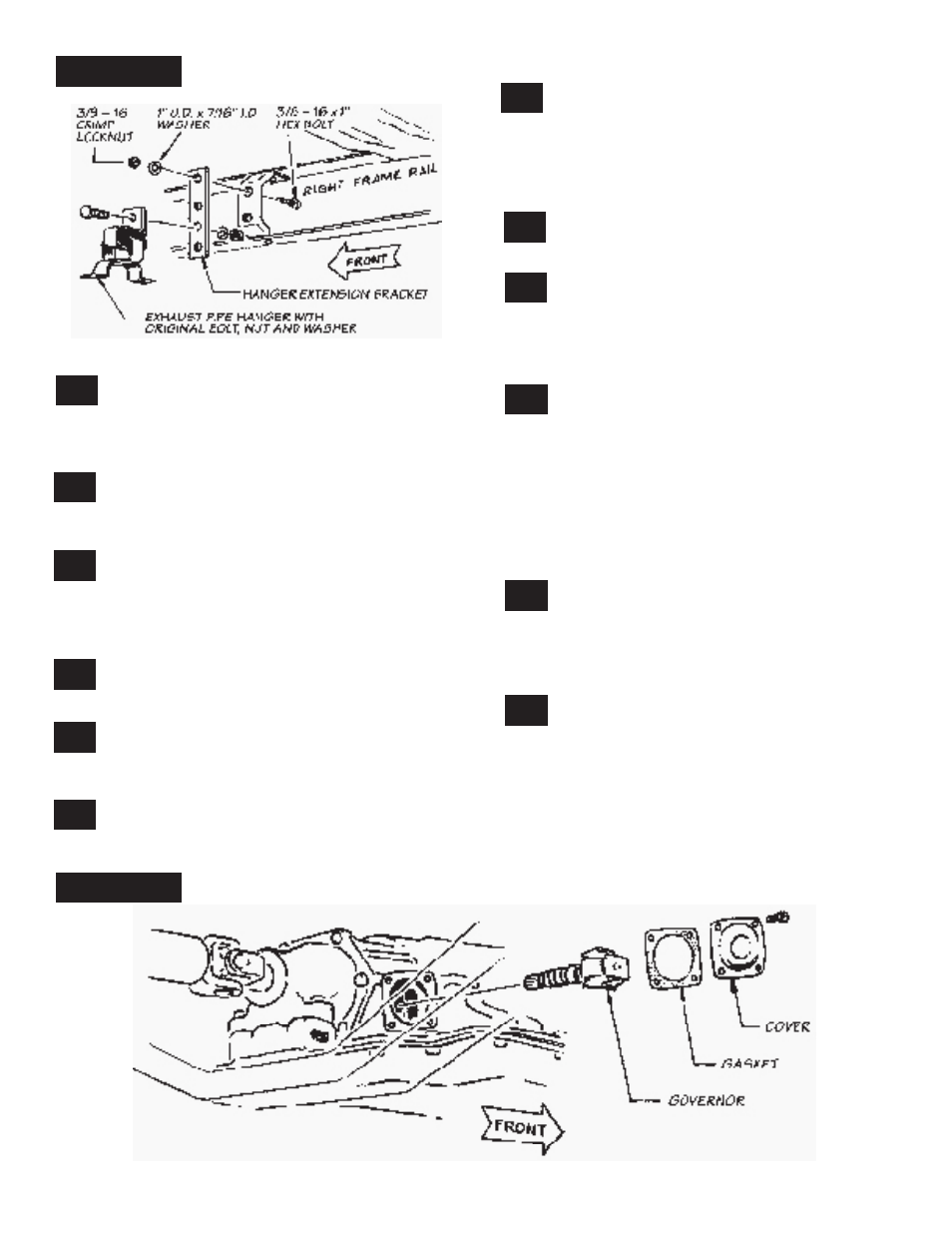

Remove the forwardmost exhaust pipe

hanger from the right hand frame rail. Install

the hanger extension bracket, provided, on the

frame rail at this location. use two

3

⁄

8

–16 x 1” hex

bolts, two 1” O.d. x

7

⁄

16

” i.d. flat washers and two

3

⁄

8

–16 crimp locknuts to secure the extension. See

Figure

15.

Reinstall the exhaust pipe hanger to the

extension bracket using the original bolt,

nut, and washer.

Install the Banks exhaust head pipes and

muffler using the original nuts, wash-

ers, springs, etc. use anti-sieze on the threads.

Position the pipes such that they can mount in the

two forwardmost exhaust pipe hangers. Tighten

all nuts, clamps, etc. See Figure

1.

Working from the muffler back, install the

tail pipe sections most appropriate for your

vehicle. Because of various chassis lengths and

configurations, your tail pipe hangers may or may

not line up properly for the tail pipe routing. We

have provided three universal tail pipe hangers

that may be attached to crossmembers, frame

rails, etc. with the remaining

3

⁄

8

– 16 x 1” hex

bolts, nuts, and washers. see figure 1 for tail pipe

assembly. Maintain 1

1

⁄

2

” of clearance to frame and

body to prevent rattles and hot spots.

Install the chrome tail pipe extension tip

and chrome tailpipe heat shield per Figure

1.

extension tip may be slid in or out over tail

pipe until desired length is obtained for body

width. Then clamp extension to tail pipe using 3”

u-clamp.

Install new vacuum hose, provided, from

connection on heat riser (ePR) valve to

metal vacuum line. Keep this hose as far as pos-

sible from exhaust system heat. Plastic cable ties

are provided to attach the hose to crossmembers,

etc. The metal vacuum line may be bent slightly to

aim it toward the ePR valve.

32.

33.

34.

35.

36.

37.

11

P.n. 96341

29.

30.

31.

fiGure 16

fiGure 15

28.

26.

27.