Implement and steering controls, Ergonomically designed for ease of operation – Milton CAT D9T User Manual

Page 6

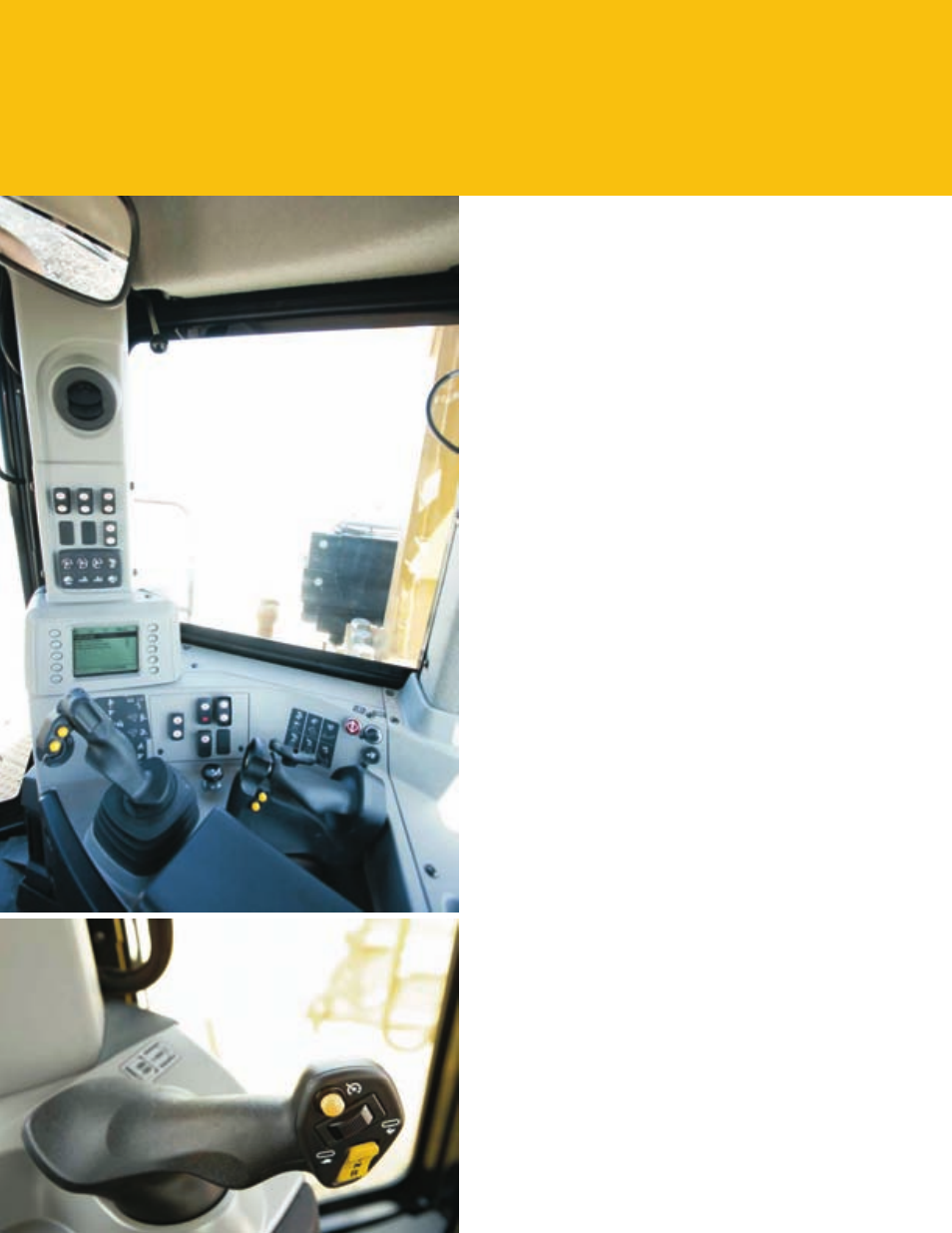

Implement and Steering Controls

Ergonomically designed for ease of operation

Dozer Control Lever

A low-effort electronic dozer control handle gives the

operator control of all dozer functions with one hand.

Fore/aft movement of the control handle lowers and raises

the blade. Left/right movement directionally tilts the blade.

Blade response and blade float can be set/adjusted using the

Advisor System.

The thumb lever at the top of the handle and trigger switch

controls blade pitch fore and aft when equipped with dual tilt.

Dual tilt also provides automated blade assist control capability.

Electronic Ripper Control

A rigidly mounted handgrip provides firm support for

the operator even when ripping in the roughest terrain.

The low effort thumb lever controls raising and lowering.

The finger lever controls shank-in and shank-out positioning.

Performance Monitor

The monitoring system collects machine data and provides

real-time feedback on machine productivity to optimize

performance. Data summaries can be sent to off-board tools

for site managers to review.

Terrain for Grading (optional)

Provides high precision management of dozing and grading

applications for enhanced safety, productivity and efficiency.

The system enables an electronic site plan to be sent to the

machine from the office in real-time, directing the operator

where to cut and fill.

Automatic Ripper Control (optional)

A new feature that reduces operator fatigue and decreases

wear and tear on the machine. This is done by monitoring

the tractor ground speed with the new cab mounted Global

Navigation Satellite System (GNSS) to automatically adjust

engine speed and ripper depth to minimize track slip.

Autocarry (optional)

Enhances operators productivity by coninuously monitoring

ground speed and automatically adjusts blade load.

Cat Grade Control (optional)

Integrates traditional machine control and guidance with

machine hardware and software to help improve productivity,

usability, reliability and value.

Cat Grade Control software is enhanced to not only

automatically guide the blade to the desired design contours,

but also integrated with Autocarry to sense and automatically

control the load of the blade for improved performance and

efficient blade loading in high production dozing applications.