Vishay high power products – C&H Technology 113MT..KPbF Series User Manual

Page 4

Document Number: 94353

For technical questions, contact: [email protected]

www.vishay.com

Revision: 29-Apr-08

3

53-93-113MT..KPbF Series

Three Phase Controlled Bridge

(Power Modules), 55 A to 110 A

Vishay High Power Products

Note

(1)

Available with dV/dt = 1000 V/µs, to complete code add S90 i. e. 113MT160KBS90

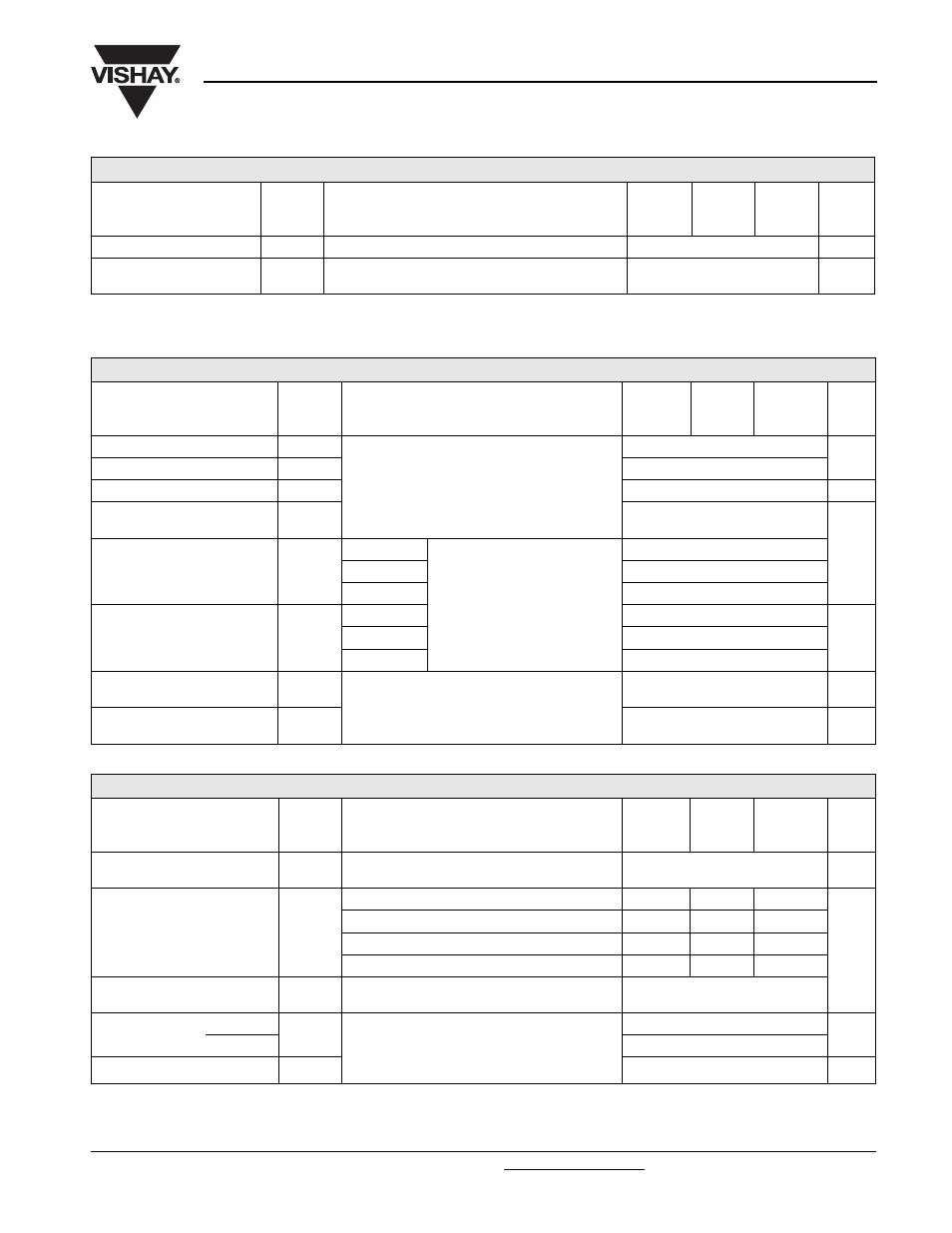

BLOCKING

PARAMETER

SYMBOL

TEST CONDITIONS

53MT.K

52MT.K

51MT.K

93MT.K

92MT.K

91MT.K

113MT.K

112MT.K

111MT.K

UNITS

RMS isolation voltage

V

ISOL

T

J

= 25 °C all terminal shorted, f = 50 Hz, t = 1 s

4000

V

Maximum critical rate of rise

of off-state voltage

dV/dt

(1)

T

J

= T

J

maximum, linear to 0.67 V

DRM

,

gate open circuit

500

V/µs

TRIGGERING

PARAMETER

SYMBOL

TEST CONDITIONS

53MT.K

52MT.K

51MT.K

93MT.K

92MT.K

91MT.K

113MT.K

112MT.K

111MT.K

UNITS

Maximum peak gate power

P

GM

T

J

= T

J

maximum

10

W

Maximum average gate power

P

G(AV)

2.5

Maximum peak gate current

I

GM

2.5

A

Maximum peak negative

gate voltage

- V

GT

10

V

Maximum required DC gate

voltage to trigger

V

GT

T

J

= - 40 °C

Anode supply = 6 V,

resistive load

4.0

T

J

= 25 °C

2.5

T

J

= 125 °C

1.7

Maximum required DC gate

current to trigger

I

GT

T

J

= - 40 °C

270

mA

T

J

= 25 °C

150

T

J

= 125 °C

80

Maximum gate voltage

that will not trigger

V

GD

T

J

= T

J

maximum, rated V

DRM

applied

0.25

V

Maximum gate current

that will not trigger

I

GD

6

mA

THERMAL AND MECHANICAL SPECIFICATIONS

PARAMETER

SYMBOL

TEST CONDITIONS

53MT.K

52MT.K

51MT.K

93MT.K

92MT.K

91MT.K

113MT.K

112MT.K

111MT.K

UNITS

Maximum junction operating

and storage temperature range

T

J

, T

Stg

- 40 to 125

°C

Maximum thermal resistance,

junction to case

R

thJC

DC operation per module

0.18

0.14

0.12

K/W

DC operation per junction

1.07

0.86

0.70

120 °C rect. conduction angle per module

0.19

0.15

0.12

120 °C rect. conduction angle per junction

1.17

0.91

0.74

Maximum thermal resistance,

case to heatsink per module

R

thCS

Mounting surface smooth, flat and grased

0.03

Mounting

torque ± 10 %

to heatsink

A mounting compound is recommended and

the torque should be rechecked after a period

of 3 hours to allow for the spread of the

compound. Lubricated threads.

4 to 6

Nm

to terminal

3 to 4

Approximate weight

225

g