Rtop, Vishay sfernice, Choice of the heatsink – C&H Technology RTOP User Manual

Page 4: Overloads, Recommendations for mounting onto a heatsink, Energy curve

www.vishay.com

For technical questions, contact: [email protected]

Document Number: 50045

3

Revision: 14-Nov-08

RTOP

Vishay Sfernice

Power Resistor for Mounting onto a Heatsink

Thick Film Technology

CHOICE OF THE HEATSINK

The user must choose the heatsink according to the working

conditions of the component (power, room temperature).

Maximum working temperature must not exceed 125 °C.

The dissipated power is simply calculated by the following

ratio:

P: Expressed

in

W

ΔT:

Difference between maximum working

temperature and room temperature.

R

TH (j - c)

: Thermal resistance value measured between

resistive layer and outer side of the resistor. It is

the thermal resistance of the component (see

Table Special Features).

R

TH (c - a)

: Thermal resistance value measured between

outer side of the resistor and room temperature.

It is

the thermal resistance of the heatsink

depending on the heatsink itself (type, shape)

and the quality of the fastening device.

Example:

R

TH (c - a)

: For RTOP 200 power rating 130 W at ambient

temperature + 30 °C.

Thermal resistance (see table 1) R

TH (j - c)

: 0.5 °C/W

OVERLOADS

The applied power is 2.5 x rated power for 5 s with a max.

voltage of 2 x nominal voltage.

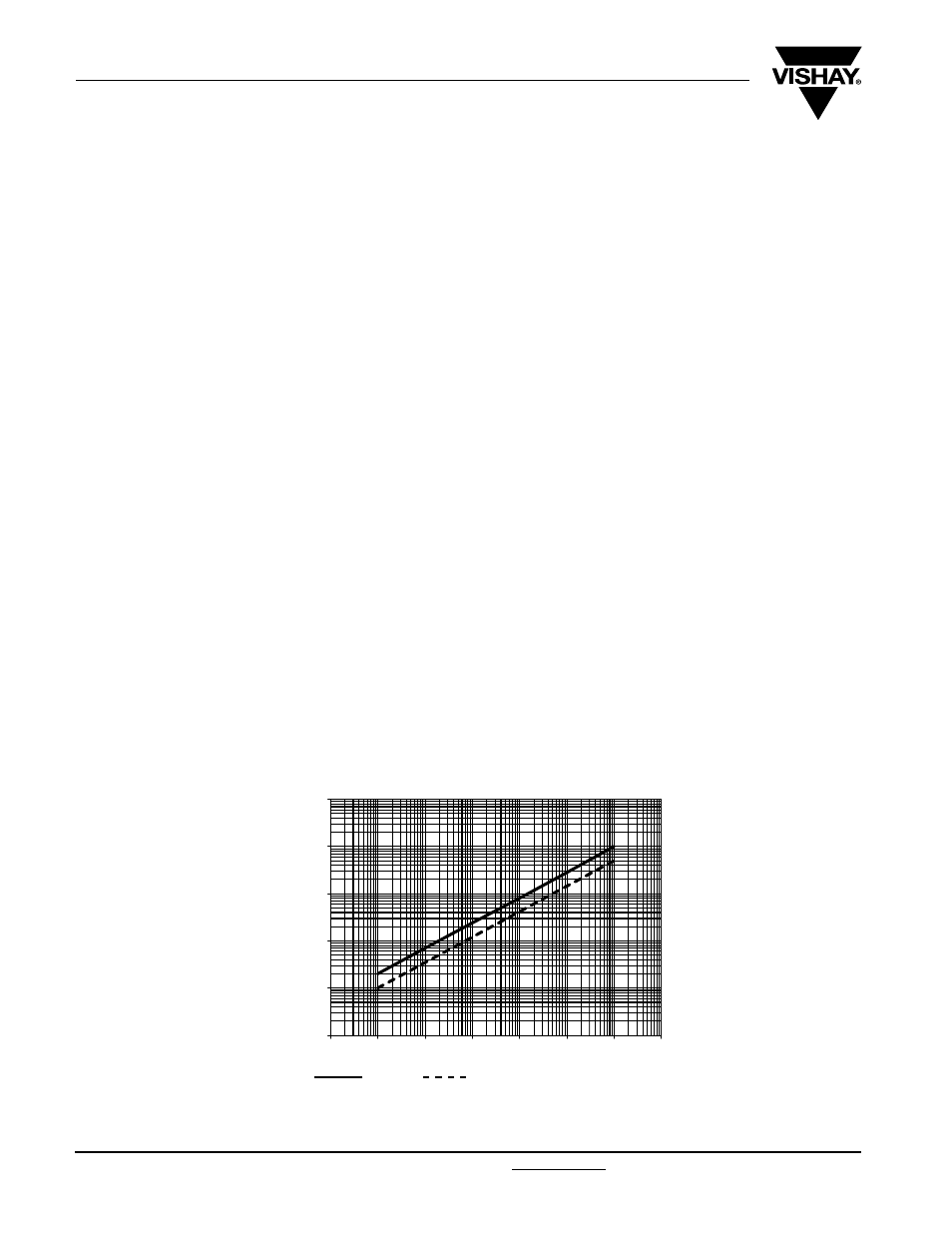

Accidental overload: The values indicated in the graph

below are applicable to resistors in air or mounted onto a

heatsink.

In case of multi-resistor devices, (DRTOP, TROP and

QROP) the results apply to each resistor value in the device.

RECOMMENDATIONS FOR MOUNTING

ONTO A HEATSINK

Surfaces in contact must be carefully cleaned.

The heatsink must have an acceptable flatness:

from 0.05 mm to 0.1 mm/100 mm.

Roughness of the heater must be around 6.3 µm.

In order to improve thermal conductivity, surfaces in contact

(alumina, heatsink) are laid on with a silicone grease (type SI

340 from Rhône-Poulenc or Dow 340 from Dow Corning).

Tightening torque on heater: 2 Nm

For the electrical connections, it is recommended to use

M4 x 6 screws and if necessary a washer of 1mm thickness.

The recommended screw tightening torque is 1 Nm.

P

ΔT

R

TH j

c

–

(

)

R

TH c

a

–

(

)

+

[

]

------------------------------------------------------------- 1

( )

=

ΔT 125 °C - 30 °C - 95 °C

≤

≤

R

TH (j - c)

R

TH (c - a)

ΔT

P

-------

95

130

----------

0.73 °C/W

=

=

=

+

R

TH (j - c)

0.5 °C/W

≤

R

TH (c - a)

0.73 °C/W - 0.5 °C/W

0.23 °C/W

≤

≤

ENERGY CURVE

OVERLOAD DURATION IN SECONDS

ENERGY IN JOULES

1.10

-7

1.10

-6

1.10

-5

1.10

-4

1.10

-3

1.10

-2

1.10

-1

1

RTOP

DRTOP

0.01

0.1

1

10

100

1000