7 maintenance and fault rectification, 1 maintenance, 2 rectify faults – VEGA VEGATOR 112 User Manual

Page 17

17

7 Maintenance and fault rectification

VEGATOR 112 •

46106-EN-131217

7 Maintenance and fault rectification

7.1 Maintenance

If the instrument is used properly, no special maintenance is required

in normal operation.

7.2 Rectify faults

A maximum of reliability is ensured. Nevertheless, faults can occur

during operation. These may be caused by the following, e.g.:

•

Measured value from sensor not correct

•

Voltage supply

•

Interference on the cables

The first measure to be taken is to check the input and output signals.

The procedure is described as follows. In many cases the causes can

be determined this way and faults can be easily rectified.

Should these measures not be successful, please call in urgent cases

the VEGA service hotline under the phone no. +49 1805 858550.

The hotline is available to you 7 days a week round-the-clock. Since

we offer this service world-wide, the support is only available in the

English language. The service is free of charge, only the standard

telephone costs will be charged.

Depending on the reason for the fault and the measures taken, the

steps described in chapter "Set up" may have to be carried out again.

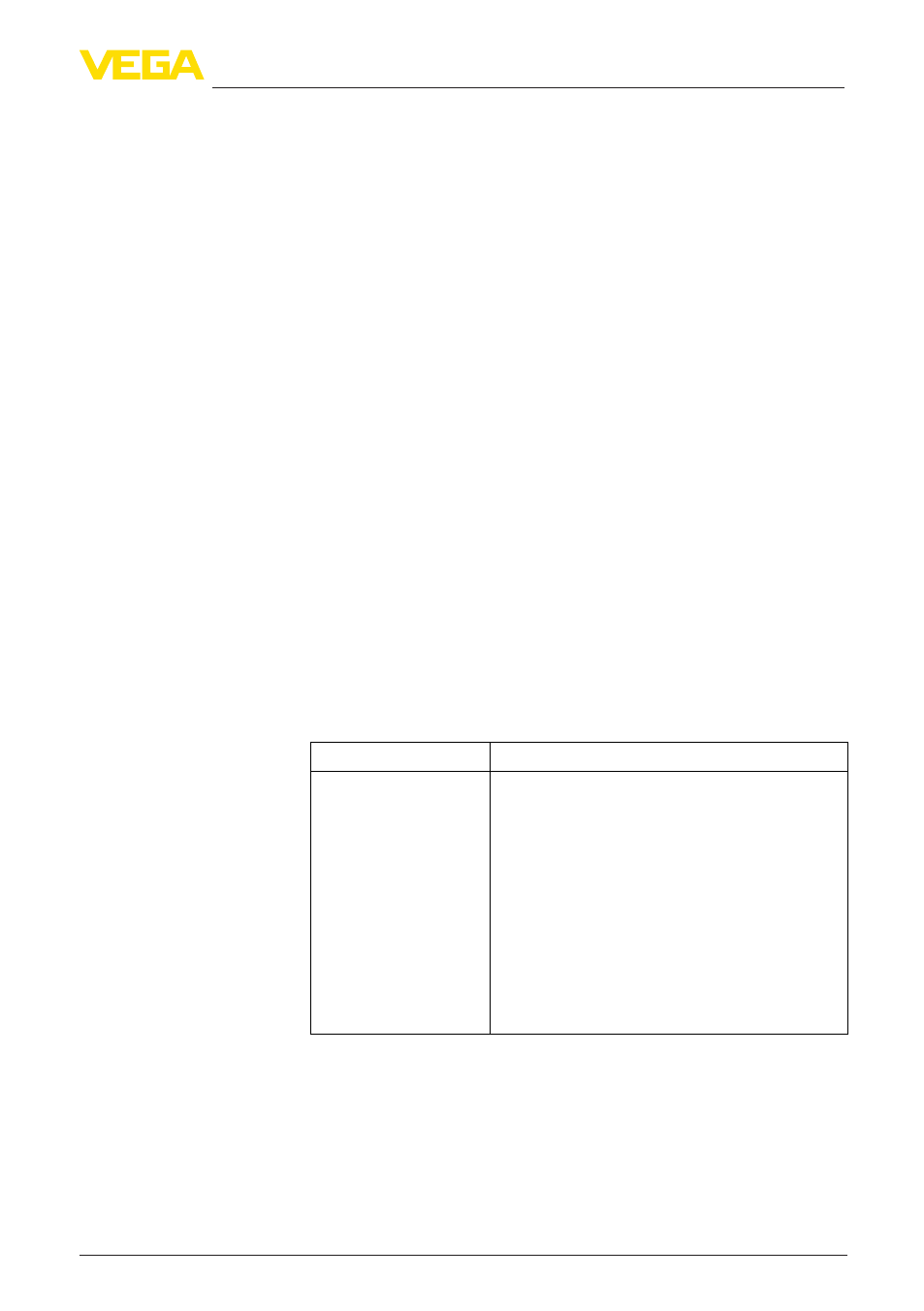

Cause

Rectification

Sensor not connected

correctly

– In Ex systems, make sure that the Ex protection

is not influenced by the measuring instruments

used.

– Measure the current and voltage on the connec-

tion cable to the sensor

– Faults in the sensor that cause a current change

under 0.05 mA or over 6.8 mA lead to a fault

signal with signal conditioning instruments.

– In idle state, the terminal voltage (without sensor)

is at least 8.2 V

– The signal conditioning instrument has an inner

resistance of 1 kOhm. With this, the voltages for

the different currents can be calculated.

Failure reasons

Fault rectification

24 hour service hotline

Reaction after fault recti-

fication

Red fault LED lights