VEGA VEGAPULS 68 (≥ 2.0.0 - ≥ 4.0.0) Modbus and Levelmaster protocol User Manual

Page 64

64

11 Supplement

VEGAPULS 68 • Modbus and Levelmaster protocol

41370-EN-121011

Ʋ Horn antenna ø 95 mm (3.74 in)

8°

Ʋ Parabolic antenna

3°

Emitted HF power (depending on the parameter adjustment)

3)

Ʋ Average spectral transmission power

density

-14 dBm/MHz EIRP

Ʋ Max. spectral transmission power

density

+43 dBm/50 MHz EIRP

Ʋ Max. power density in a distance of

1 m

< 1 µW/cm²

Ambient conditions

Ambient, storage and transport tempera-

ture

-40 … +80 °C (-40 … +176 °F)

Process conditions

For the process conditions, please also note the specifications on the type label. The lowest value

always applies.

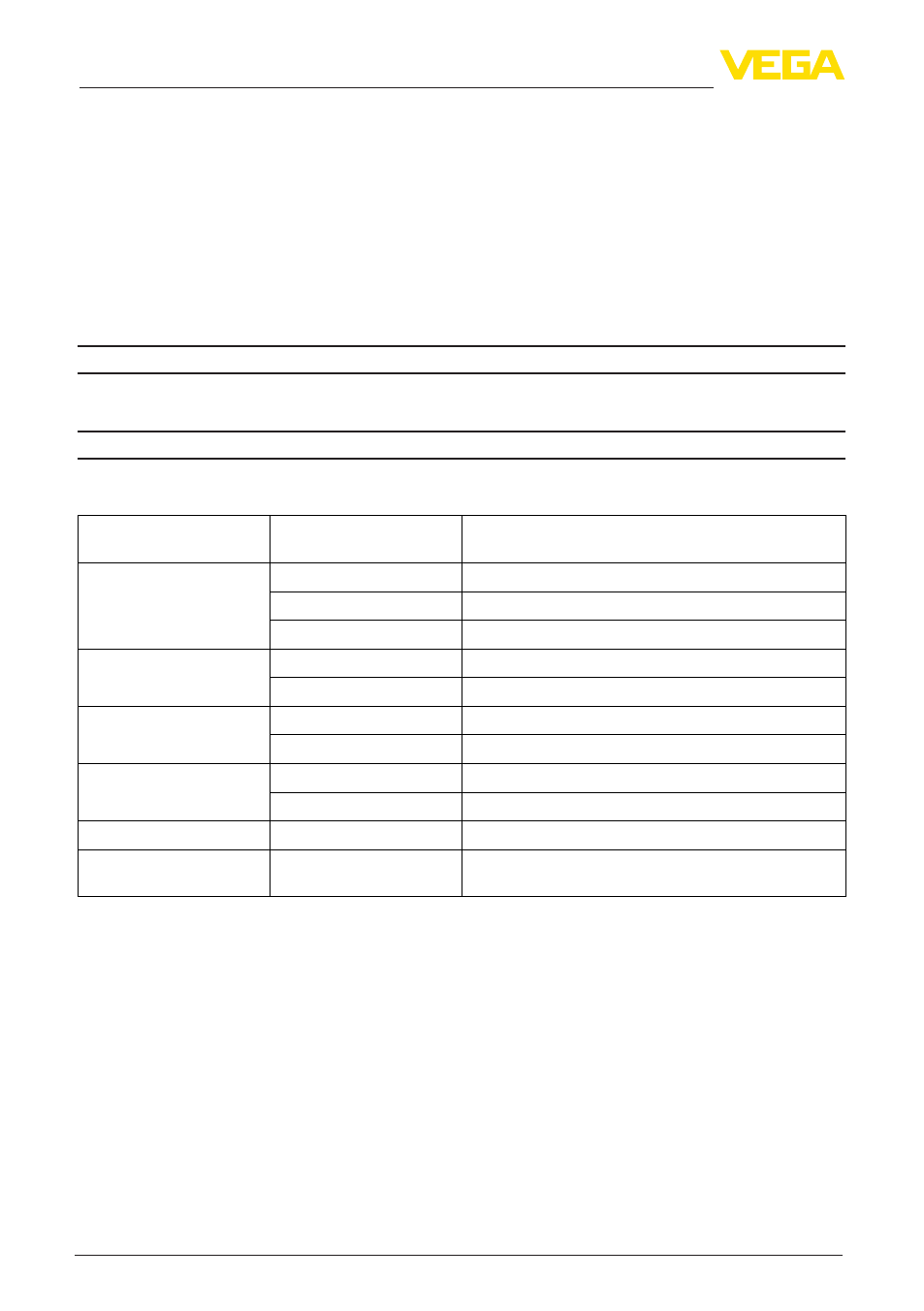

Seal

Antenna impedance

cone

Process temperature (measured on the process

fitting)

FKM (SHS FPM 70C3

GLT)

PTFE

-40 … +130 °C (-40 … +266 °F)

PTFE

4)

-40 … +200 °C (-40 … +392 °F)

PEEK

5)

-40 … +200 °C (-40 … +392 °F)

FFKM (Kalrez 6375)

PTFE

-20 … +130 °C (-4 … +266 °F)

PEEK

-20 … +250 °C (-4 … +482 °F)

FFKM (Kalrez 2035)

PTFE

-15 … +130 °C (5 … +266 °F)

PEEK

-15 … +210 °C (5 … +410 °F)

FFKM (Kalrez 6230)

PTFE

-15 … +130 °C (5 … +266 °F)

PEEK

-15 … +250 °C (5 … +482 °F)

Graphite

Ceramic

-200 … +450 °C (-328 … +842 °F)

Graphite (process fitting

Hastelloy C 22)

Ceramic

-196 … +400 °C (-321 … +752 °F)

Vessel pressure - horn antenna

Ʋ Antenna impedance cone PTFE

-1 … 40 bar (-100 … 4000 kPa/-14.5 … 580 psig)

Ʋ Antenna impedance cone PP

-1 … 3 bar (-100 … 300 kPa/-14.5 … 43.5 psig)

Ʋ Antenna impedance cone PEEK

-1 … 100 bar (-100 … 10000 kPa/-14.5 … 1450 psig)

Ʋ Antenna impedance cone ceramic

-1 … 160 bar (-100 … 16000 kPa/-14.5 … 2320 psig)

Vessel pressure - parabolic antenna

-1 … 6 bar (-100 … 6000 kPa/-14.5 … 870 psig)

Vessel pressure with swivelling holder

-1 … 1 bar (-100 … 100 kPa/-14.5 … 14.5 psig)

Vessel pressure relating to the flange

nominal stage

see supplementary instructions manual "Flanges ac-

cording to DIN-EN-ASME-JIS"

3)

EIRP: Equivalent Isotropic Radiated Power

4)

Not with steam

5)

Not with steam