4 measurement error with constant level, 4 measurement error during filling – VEGA VEGAPULS 67 (≥ 2.0.0 - ≥ 4.0.0) HART - integrated accumulator User Manual

Page 54

54

9 Diagnosis, Asset Management and service

VEGAPULS 67 • HART - integrated accumulator

40795-EN-121011

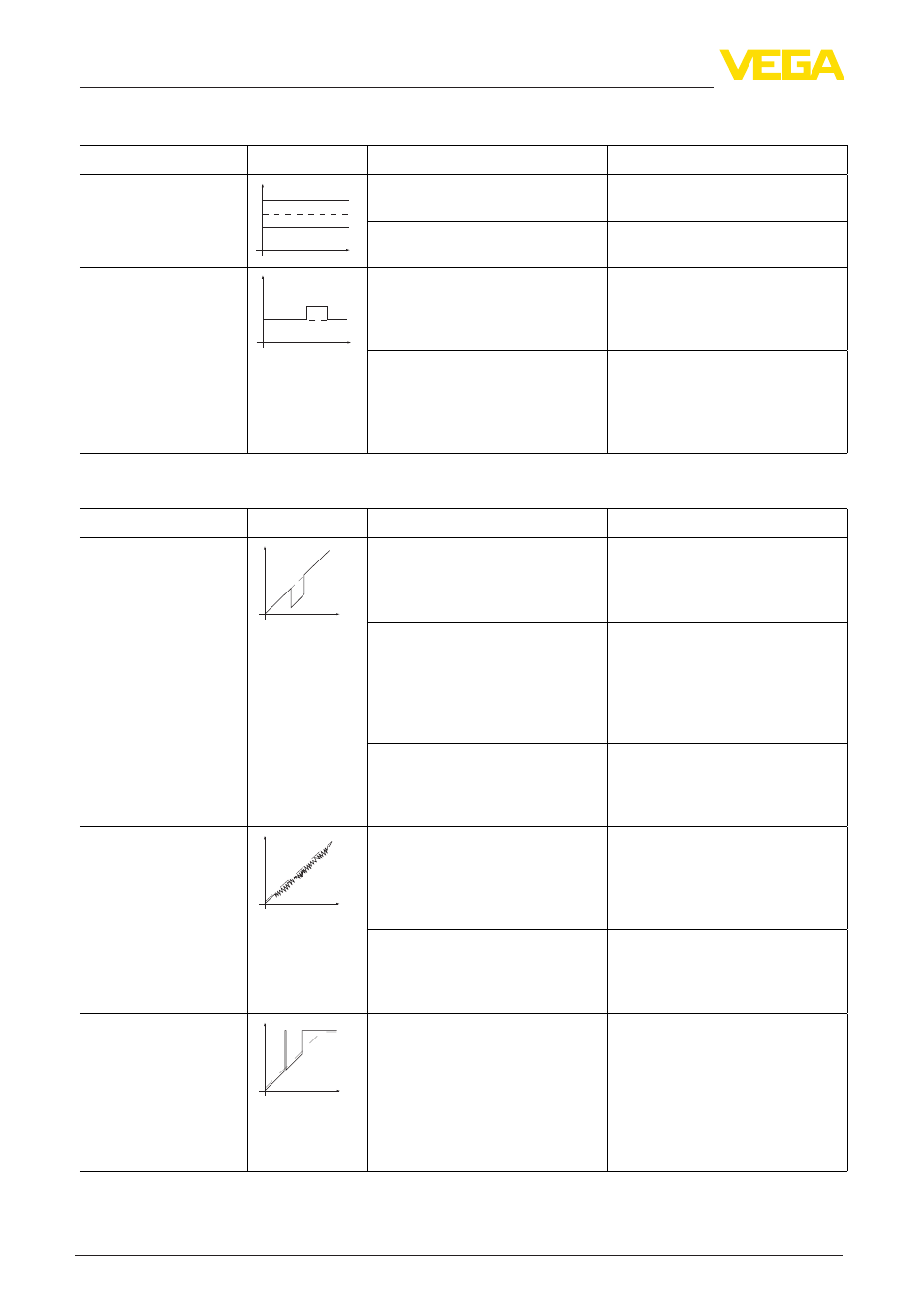

9.4 Measurement error with constant level

Fault description

Error pattern

Cause

Rectification

1. Measured value

shows a too low or too

high level

Level

time

0

– Min./max. adjustment not

correct

– Adapt min./max. adjustment

– Wrong linearization curve

– Adapt linearization curve

2. Measured value

jumps towards 100 %

Level

time

0

– Due to the process, the ampli-

tude of the product echo sinks

– A false signal suppression was

not carried out

– Carry out false signal suppres-

sion

– Amplitude or position of a

false echo has changed (e.g.

condensation, buildup); false

signal suppression no longer

matches

– Determine the reason for the

changed false echo, carry out

false signal suppression, e.g.

with condensation

9.4 Measurement error during filling

Fault description

Error pattern

Cause

Rectification

3rd measured val-

ue jumps towards 0 %

during filling

Level

time

0

– Amplitude of a multiple echo

(vessel top - product surface) is

larger than the level echo

– Check parameter "Application",

especially vessel top, product

type, dished end, high dielectric

figure, adapt if necessary

– The level echo cannot be distin-

guished from the false echo at

a false echo position (jumps to

multiple echo)

– Remove/reduce false echo:

minimize interfering installa-

tions by changing the polariza-

tion direction

– Chose a more suitable installa-

tion position

– Transverse reflection from an

extraction funnel, amplitude of

the transverse reflection larger

than the level echo

– Direct sensor to the opposite

funnel wall, avoid crossing with

the filling stream

4th measured val-

ue fluctuates around

10 … 20 %

Level

time

0

– Various echoes from an uneven

product surface, e.g. a material

cone

– Check application parameter

"Medium type" and adapt, if

necessary

– Optimize installation position

and sensor orientation

– Reflections from the product

surface via the vessel wall

(deflection)

– Select a more suitable installa-

tion position, optimize sensor

orientation, e.g. with a swivel-

ling holder

5. measured value

jumps sporadically to

100 % during filling

Level

time

0

– Varying condensation or con-

tamination on the antenna

– Carry out a false signal sup-

pression or increase false

signal suppression with con-

densation/contamination in the

close range by editing

– With bulk solids use radar sen-

sor with purging air connection

or flexible antenna cover