4 measurement error with constant level – VEGA VEGAPULS WL 61 Profibus PA User Manual

Page 31

31

7 Diagnosis, Asset Management and service

VEGAPULS WL 61 • Profibus PA

38062-EN-121011

•

Evaluation of fault messages, for example via the indicating and

adjustment module

•

Checking the output signal with 4 … 20 mA instruments

•

Treatment of measurement errors

Further comprehensive diagnostics options offer a PC with the soft-

ware PACTware and the suitable DTM. In many cases, the reasons

can be determined in this way and faults can be rectified.

The below tables show typical examples of application-related meas-

urement errors with liquids. The measurement errors are differentiated

according to the following:

•

Constant level

•

Filling

•

Emptying

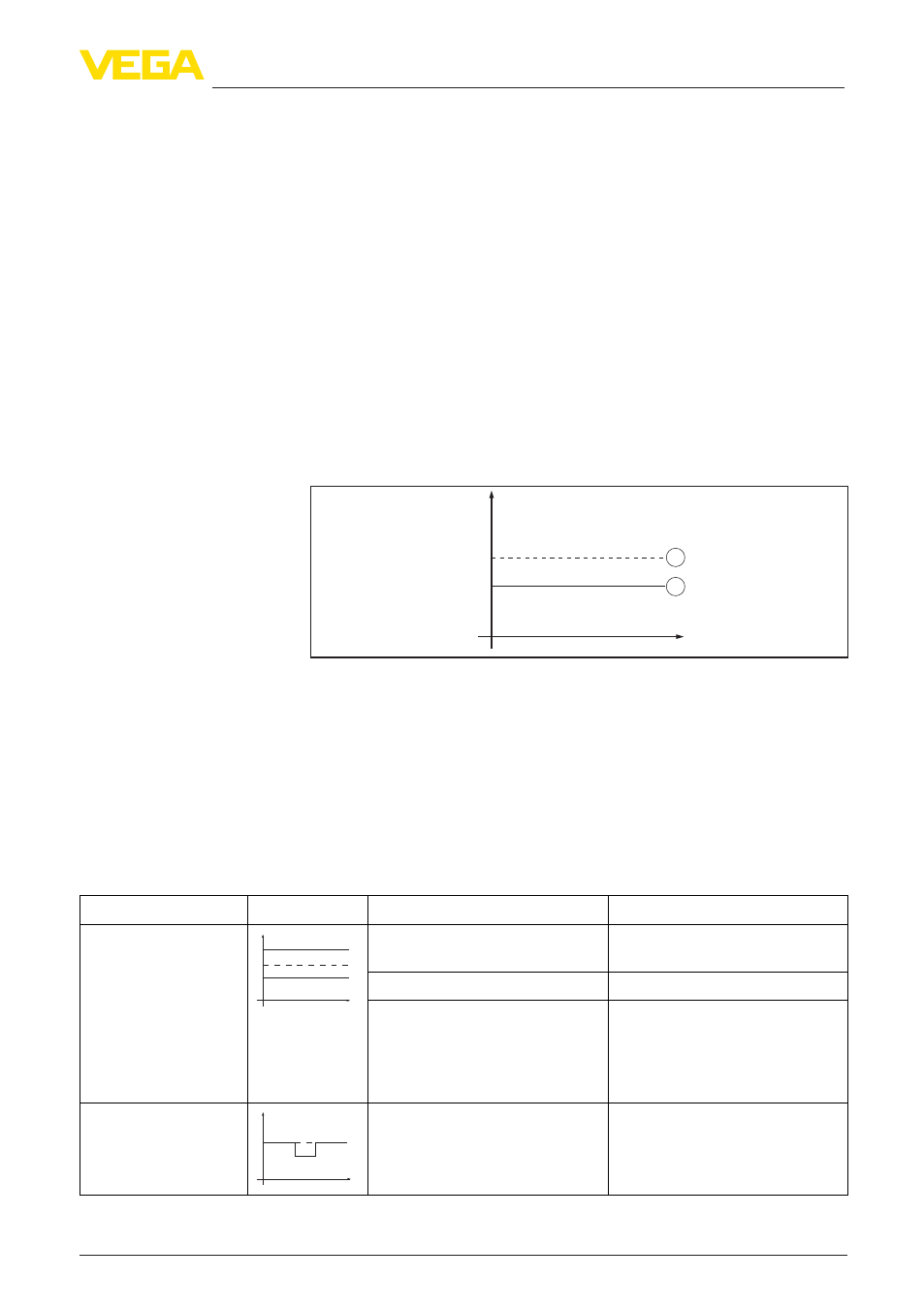

The images in column "Error pattern" show the real level with a bro-

ken line and the level displayed by the sensor as a continuous line.

1

2

Level

time

0

1 Real level

2 Level displayed by the sensor

Instructions:

•

Wherever the sensor displays a constant value, the reason could

also be the fault setting of the current output to "Hold value"

•

In case of a too low level indication, the reason could be a line

resistance that is too high

7.4 Measurement error with constant level

Fault description

Error pattern

Cause

Rectification

1. Measured value

shows a too low or too

high level

Level

time

0

– Min./max. adjustment not

correct

– Adapt min./max. adjustment

– Wrong linearization curve

– Adapt linearization curve

– Installation in a bypass tube or

standpipe, hence running time

error (small measurement error

close to 100 %/large error close

to 0 %)

– Check parameter "Application"

with respect to vessel form,

adapt if necessary (bypass,

standpipe, diameter)

2. Measured value

jumps towards 0 %

Level

time

0

– Multiple echo (vessel top,

product surface) with amplitude

higher than the level echo

– Check parameter "Application",

especially vessel top, product

type, dished end, high dielectric

figure, adapt if necessary

Treatment of measure-

ment errors with liquids