4 measurement error during filling – VEGA VEGAPULS 66 (≥ 2.0.0 - ≥ 4.0.0) enamel Profibus PA User Manual

Page 54

54

9 Diagnosis, Asset Management and service

VEGAPULS 66 enamel • Profibus PA

36529-EN-121011

9.4 Measurement error during filling

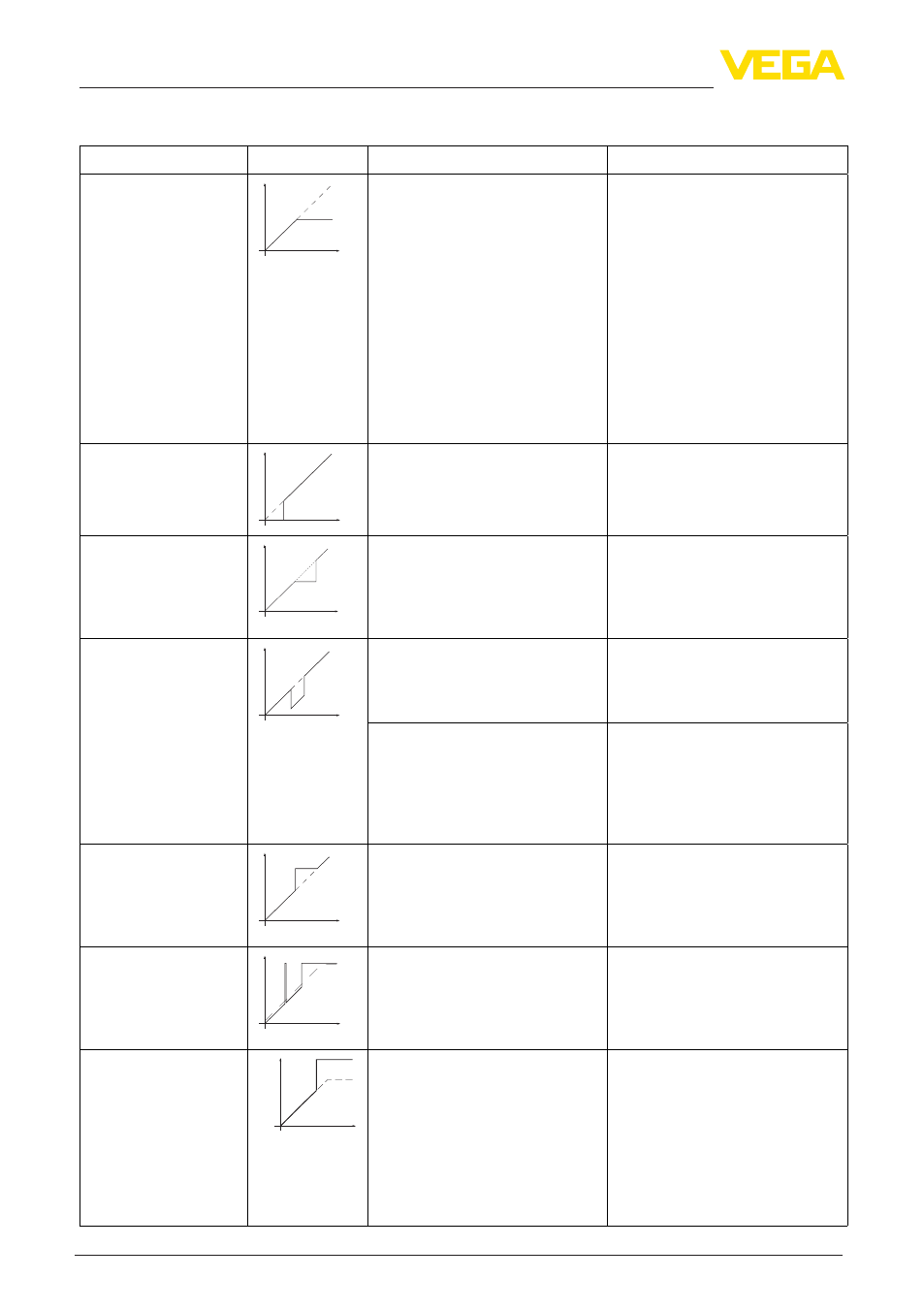

Fault description

Error pattern

Cause

Rectification

4. Measured value re-

mains unchanged

during filling

Level

time

0

– False echoes in the close range

too big or product echo too

small

– Strong foam or spout genera-

tion

– Max. adjustment not correct

– Eliminate false echoes in the

close range

– Check measurement situation:

Antenna must protrude out of

the socket, installations

– Remove contamination on the

antenna

– Minimize interfering instal-

lations in the close range by

changing the polarization

direction

– Create a new false signal sup-

pression

– Adapt max. adjustment

5. Measured value re-

mains in the bottom

section during filling

Level

time

0

– Echo from the tank bottom

larger than the product echo,

for example, with products with

ε

r

< 2.5 oil-based, solvents

– Check application parameters

Medium, Vessel height and

Floor form, adapt if necessary

6. Measured value re-

mains momentarily

unchanged during fill-

ing and then jumps to

the correct level

Level

time

0

– Turbulence on the product

surface, quick filling

– Check application parameters,

change if necessary, e.g. in

dosing vessel, reactor

7. Measured value

jumps towards 0 %

during filling

Level

time

0

– Amplitude of a multiple echo

(vessel top - product surface) is

larger than the level echo

– Check parameter "Application",

especially vessel top, product

type, dished end, high dielectric

figure, adapt if necessary

– The level echo cannot be distin-

guished from the false echo at

a false echo position (jumps to

multiple echo)

– Remove/reduce false echo:

minimize interfering installa-

tions by changing the polariza-

tion direction

– Chose a more suitable installa-

tion position

8. Measured value

jumps towards 100 %

during filling

Level

time

0

– Due to strong turbulence and

foam generation during filling,

the amplitude of the product

echo sinks. Measured value

jumps to the false echo

– Carry out false signal suppres-

sion

9. Measured value

jumps sporadically to

100 % during filling

Level

time

0

– Varying condensation or con-

tamination on the antenna

– Carry out a false signal sup-

pression or increase false

signal suppression with con-

densation/contamination in the

close range by editing

10. Measured value

jumps to ≥ 100 % or

0 m distance

Leve

l

time

0

– Level echo is no longer

detected in the close range

due to foam generation or false

echoes in the close range. The

sensor goes into overfill protec-

tion mode. The max. level (0 m

distance) as well as the status

message "Overfill protection"

are outputted.

– Check measuring site: Antenna

must protrude out of the socket

– Remove contamination on the

antenna

– Use a sensor with a more suit-

able antenna