Measurement error during filling – VEGA VEGAPULS SR 68 4 … 20 mA_HART two-wire User Manual

Page 65

65

9 Diagnosis, Asset Management and service

VEGAPULS SR 68 • 4 … 20 mA/HART two-wire

38294-EN-130624

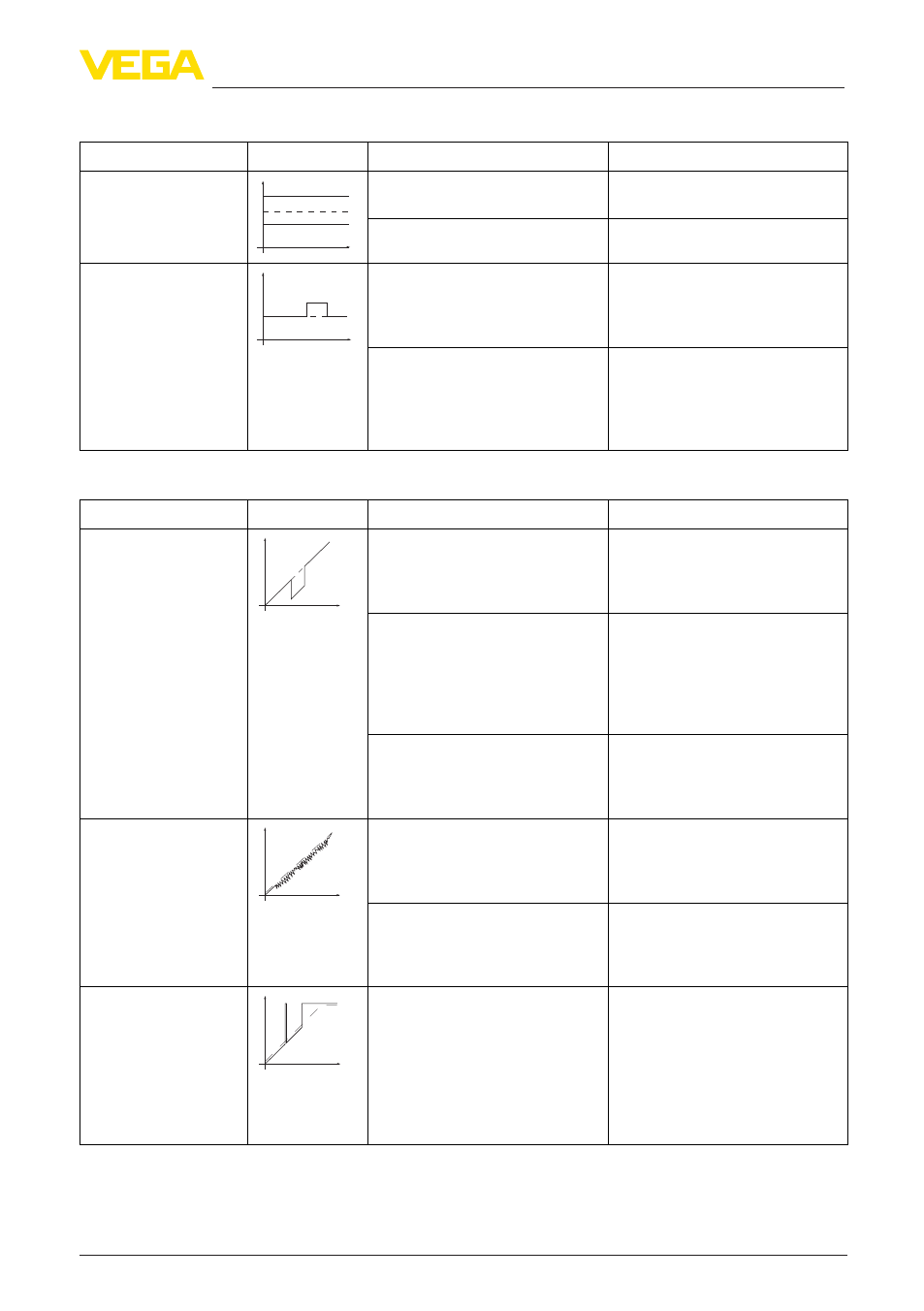

Measurement error with constant level

Fault description

Error pattern

Cause

Rectification

1. Measured value

shows a too low or too

high level

Level

time

0

– Min./max. adjustment not

correct

– Adapt min./max. adjustment

– Wrong linearization curve

– Adapt linearization curve

2. Measured value

jumps towards 100 %

Level

time

0

– Due to the process, the ampli-

tude of the product echo sinks

– A false signal suppression was

not carried out

– Carry out a false signal sup-

pression

– Amplitude or position of a

false echo has changed (e.g.

condensation, buildup); false

signal suppression no longer

matches

– Determine the reason for the

changed false echoes, carry

out false signal suppression,

e.g. with condensation

Measurement error during filling

Fault description

Error pattern

Cause

Rectification

3. Measured value

jumps towards 0 %

during filling

Level

time

0

– Amplitude of a multiple echo

(vessel top - product surface) is

larger than the level echo

– Check parameter "Application",

especially vessel top, product

type, dished end, high dielectric

figure, adapt if necessary

– The level echo cannot be distin-

guished from the false echo at

a false echo position (jumps to

multiple echo)

– Remove/reduce false echo:

minimize interfering installa-

tions by changing the polariza-

tion direction

– Chose a more suitable installa-

tion position

– Transverse reflection from an

extraction funnel, amplitude of

the transverse reflection larger

than the level echo

– Direct sensor to the opposite

funnel wall, avoid crossing with

the filling stream

4. Measured val-

ue fluctuates around

10 … 20 %

Level

time

0

– Various echoes from an uneven

product surface, e.g. a material

cone

– Check parameter "Medium

type" and adapt, if necessary

– Optimize installation position

and sensor orientation

– Reflections from the product

surface via the vessel wall

(deflection)

– Select a more suitable installa-

tion position, optimize sensor

orientation, e.g. with a swivel-

ling holder

5. Measured value

jumps sporadically to

100 % during filling

Level

time

0

– Changing condensation or con-

tamination on the antenna

– Carry out a false signal sup-

pression or increase false

signal suppression with con-

densation/contamination in the

close range by editing

– With bulk solids use radar sen-

sor with purging air connection

or flexible antenna cover