VEGA VEGASWING 63 - two-wire User Manual

Page 14

14

4 Mounting

VEGASWING 63 • - two-wire

29232-EN-130409

long extension tube for VEGASWING 63, but check if you can mount

a VEGASWING 61 level switch on the side of the vessel in horizontal

position.

Extreme vibration caused by the process or the equipment, e.g.

agitators or turbulence in the vessel, can cause the extension tube

of VEGASWING 63 to vibrate in resonance. This leads to increased

stress on the upper weld joint. Should a longer tube version be neces-

sary, you can provide a suitable support directly above the tuning fork

to secure the extension tube.

This measure applies mainly to applications in Ex areas category 1G

or WHG. Make sure that the tube is not subject to bending stress due

to this measure.

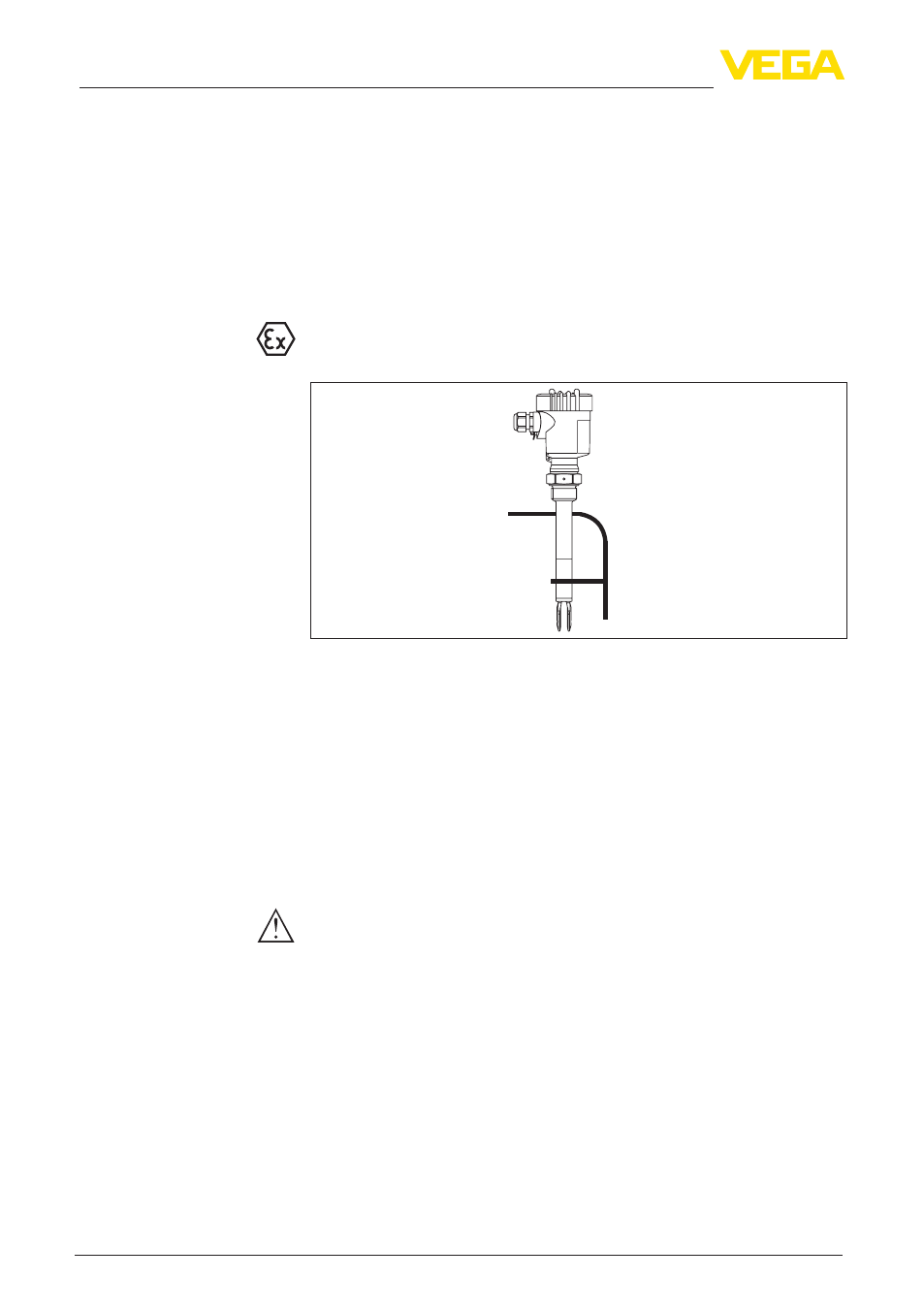

Fig. 9: Lateral straining of VEGASWING 63

Instruments with enamel coating should be treated very carefully and

shocks should be avoided. Unpack VEGASWING 63 directly before

installation. Insert VEGASWING 63 carefully into the vessel opening

and avoid touching any sharp vessel parts.

The gas-tight leadthrough avoids due to a second sealing the

uncontrolled penetration of the medium. The lifetime of the gastight

leadthrough depends ont he chemical resistance of the materials.

See "Technical data".

Caution:

If it is determined (e.g. by an error message of VEGASWING 63) that

medium has already penetrated into the vibrating element, the instru-

ment must be exchanged immediately.

Enamel coating

Gas-tight leadthrough