2 instructions for installation – VEGA VEGASWING 63 - two-wire User Manual

Page 12

12

4 Mounting

VEGASWING 63 • - two-wire

29232-EN-130409

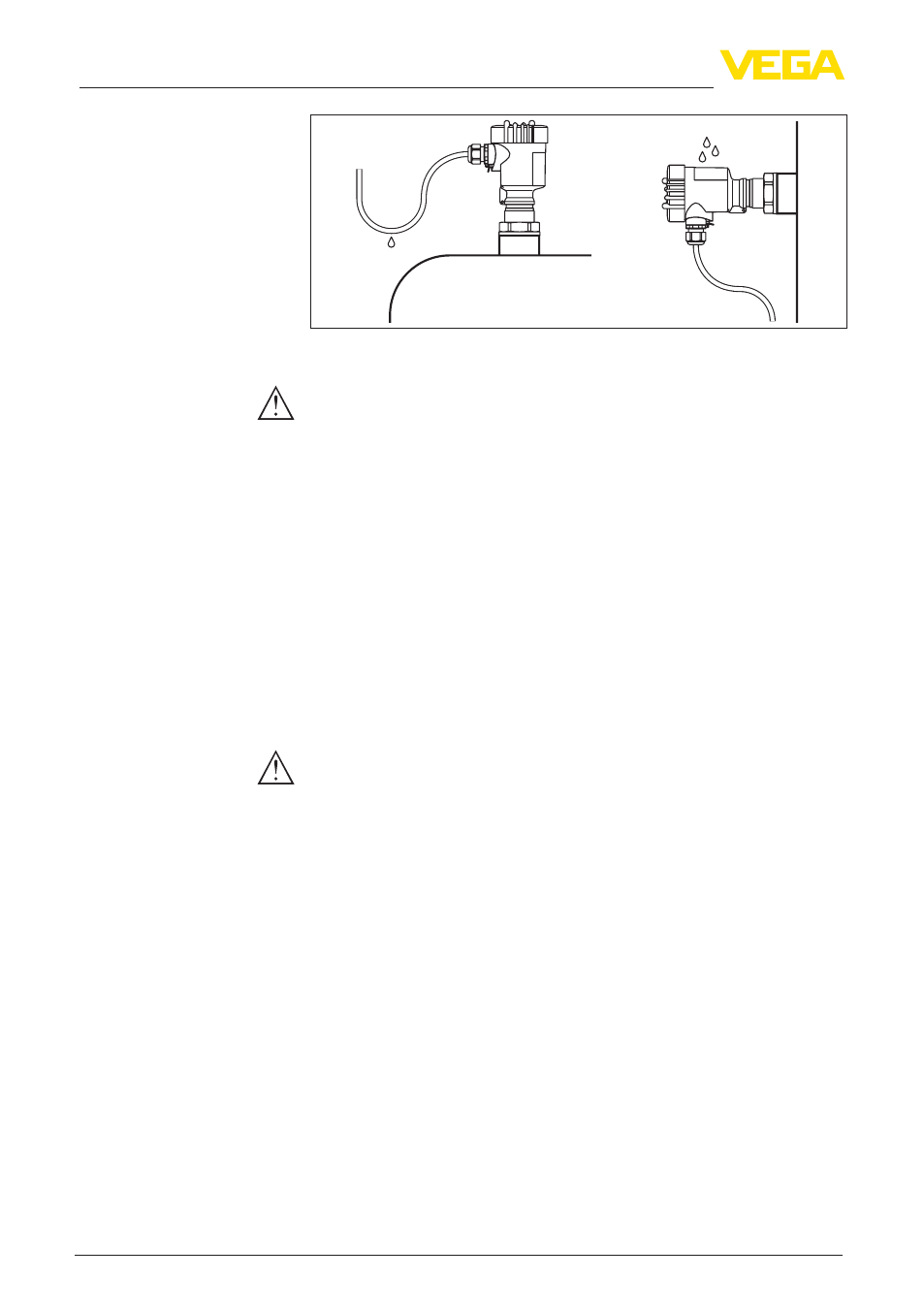

Fig. 6: Measures against moisture penetration

Caution:

Do not hold VEGASWING 63 on the tuning fork. Particularly with

flange or tube versions, the tuning fork can be damaged just by the

weight of the instrument. Transport coated instruments very carefully

and avoid touching the tuning fork.

Remove the packaging or the protective cover just before installation.

The process fitting must be sealed if there is gauge or low pressure in

the vessel. Before use, check if the seal material is resistant against

the measured product and the process temperature.

The max. permissible pressure is specified in chapter "Technical

data" or on the type label of the sensor.

The vibrating level switch is a measuring instrument and must be

treated accordingly. Bending the vibrating element will destroy the

instrument.

Warning:

The housing must not be used to screw the instrument in! Applying

tightening force can damage internal parts of the housing.

Use the hexagon above the thread for screwing in.

4.2 Instructions for installation

VEGASWING 63 has a defined thread starting point. This means

that every VEGASWING 63 is in the same fork position after being

screwed in. Remove therefore the supplied seal from the thread of

VEGASWING 63. This seal is not required when using a welded

socket with O-ring in front.

Keep in mind that this welded socket is not suitable for coated instru-

ment versions.

Screw VEGASWING 63 completely into the welded socket. The

later position can be determined already before welding. Mark the

appropriate position of the welded socket. Before welding, unscrew

VEGASWING 63 and remove the rubber ring from the welded socket.

The welded socket has a marking (notch). Weld the socket with the

notch facing upward, or in case of pipelines (DN 32 up to DN 50),

aligned with the direction of flow.

Transport

Pressure/Vacuum

Handling

Welded socket