VEGA VEGASWING 63 - Relay (DPDT) User Manual

Page 13

13

4 Mounting

VEGASWING 63 • - Relay (DPDT)

29229-EN-130409

1

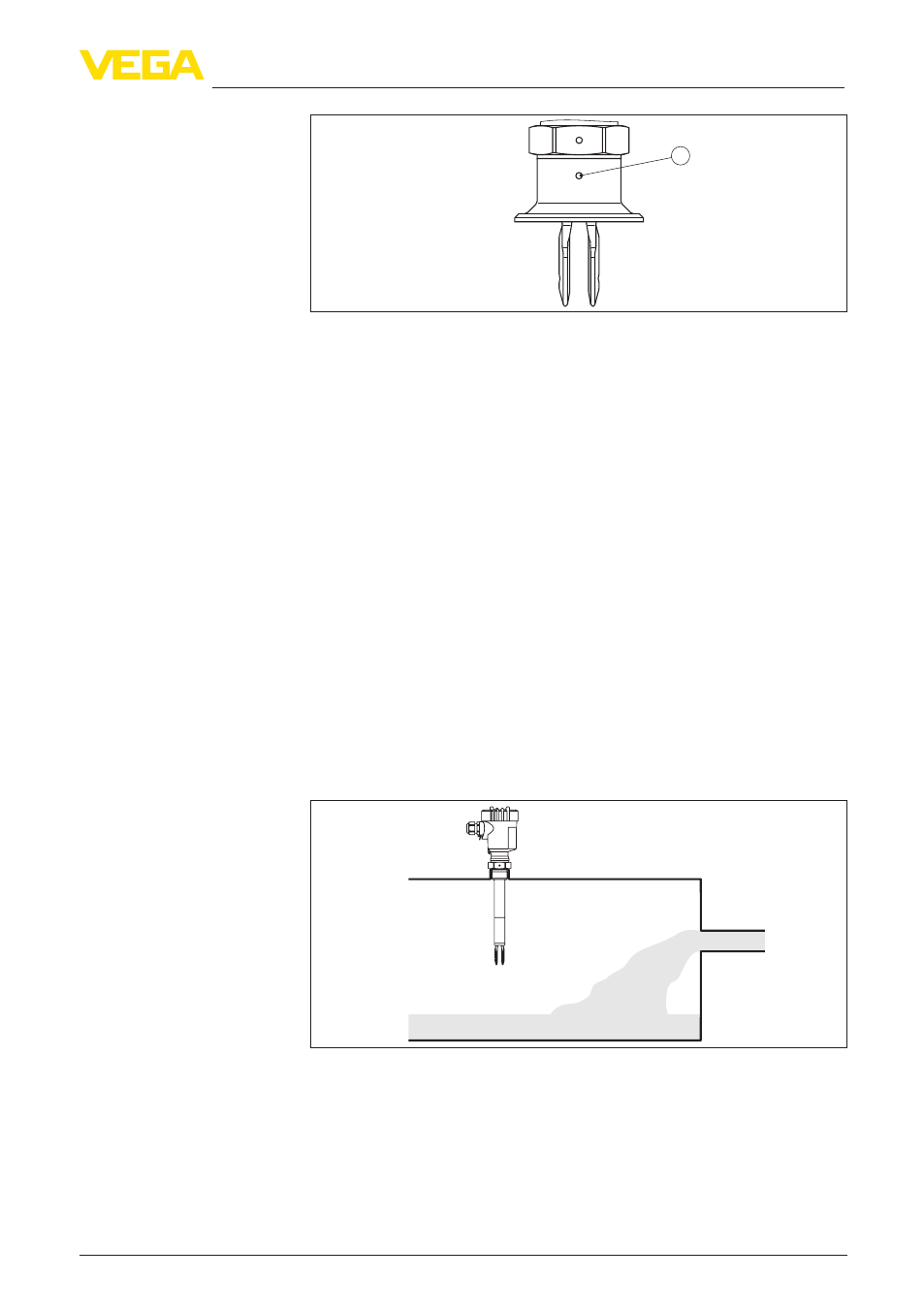

Fig. 7: Marking on the welded socket

1 Marking

In case of horizontal mounting in adhesive and viscous products,

the surfaces of the tuning fork should be vertical in order to reduce

buildup on the tuning fork. On the screwed version you will find a

marking on the hexagon. With this, you can check the position of the

tuning fork when screwing it in. When the hexagon touches the seal,

the thread can still be turned by approx. half a turn. This is sufficient to

reach the recommended installation position.

With flange versions, the fork is directed to the flange holes.

When used in adhesive and viscous products, the tuning fork should

protrude into the vessel to avoid buildup. For that reason, sockets

for flanges and mounting bosses should be avoided when mounting

horizontally.

If VEGASWING 63 is mounted in the filling stream, unwanted false

measurement signals can be generated. For this reason, mount VE-

GASWING 63 at a position in the vessel where no disturbances, e.g.

from filling openings, agitators, etc., can occur.

This applies particularly to instrument types with long extension tube.

Fig. 8: Inflowing medium

To minimise flow resistance caused by the tuning fork, VEGASWING

63 should be mounted in such a way that the surfaces of the blades

are parallel to the product movement.

Due to agitators, vibrations or similar, the level switch can be sub-

jected to strong lateral forces. For this reason, do not use an overly

Adhesive products

Inflowing medium

Flows

Agitators