Veris Technologies 3150 Soil EC Mapping System - Trouble-shooting User Manual

Page 12

Procedure #4 Spring Plunger adjustment and replacement

The spring plungers are located in the center of each coulter electrode hub cap, and are

vital to maintain good continuity through the coulter hub bearings. They are factory

preset, and should not need routine adjustment. If a continuity test shows abnormally high

resistance, the plungers should be checked. This may be performed in the following

manner:

1) Check coulter hub bearing preload by grasping coulter blade and

pushing from side to side. If there is any noticeable movement,

bearing preload is incorrect, or bearings are failing --and this can

damage the spring plunger ; see procedure #8 for adjustment or

replacement.

2)

Remove the 3/8‖ allen head set screw.

3) Remove the plunger by turning counter-clockwise.

4) Depress the spring loaded tip on a hard surface to determine if

plunger has adequate tension and can move freely.

5) If the plunger will not move freely, replace. Coat the threads with di-

electric silicone grease before installation.

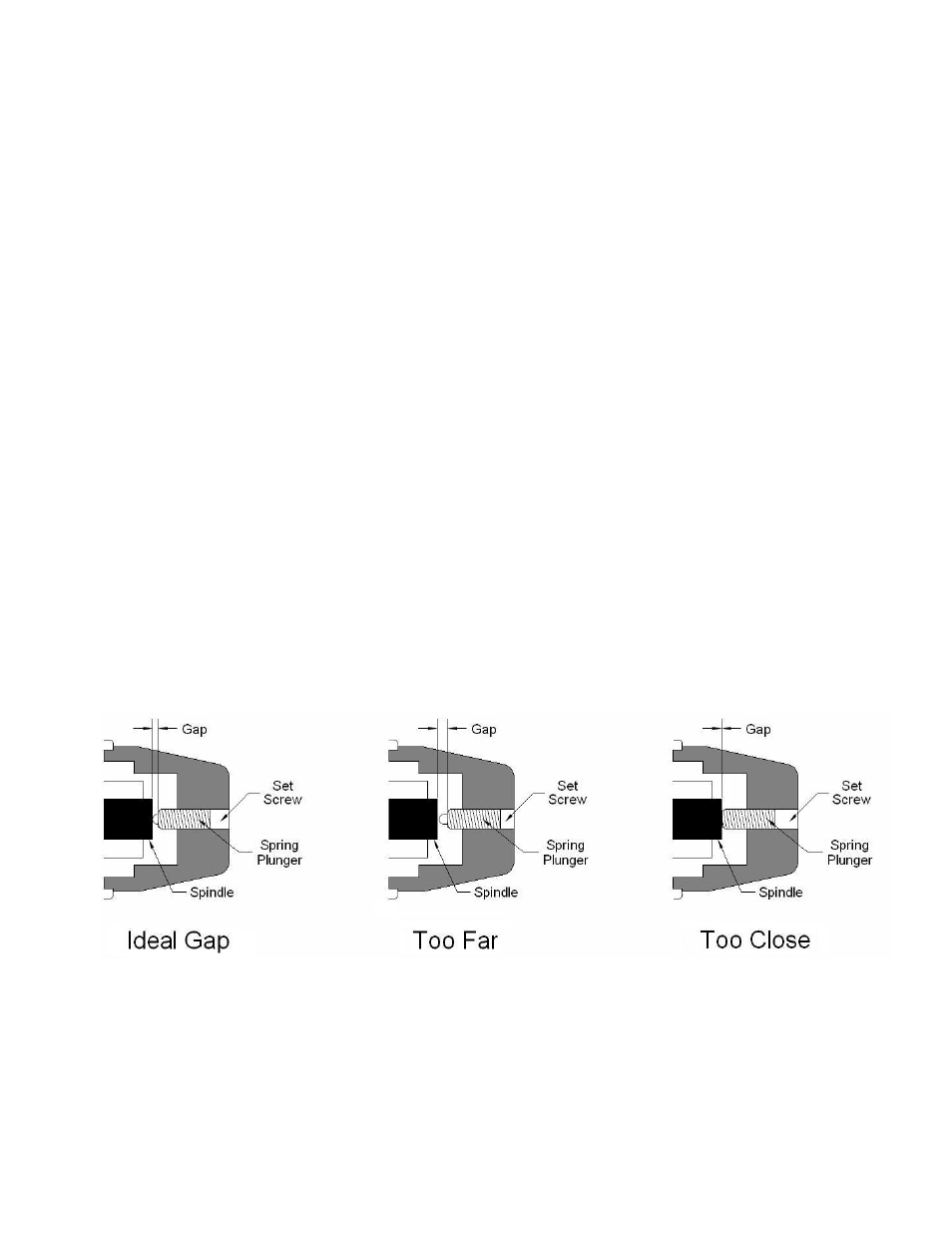

6) If the plunger appears to be in good working order, reinstall in the

hub, and adjust until it bottoms against the spindle end. Rotate 1/2

turn backward to allow adequate clearance. Improper adjustment

will result in premature failure (too little tolerance) or poor continuity

(too much tolerance). See Figure 3.12 below to view proper

clearance.

7) Reinstall locking set screw and tighten firmly on top of plunger. The

top of the setscrew should be even with the face of the hub. If not,

remove and adjust the plunger inward or outward as necessary.

8) Re-test coulter electrode continuity

Figure 3.12

In some cases, you may have to remove the hub cap to service the spring plunger, if the

plunger is rusted in the cap, or if the readings are still unsatisfactory with the new plunger

installed.