Veris Verabar V200S Installation Instructions User Manual

Page 2

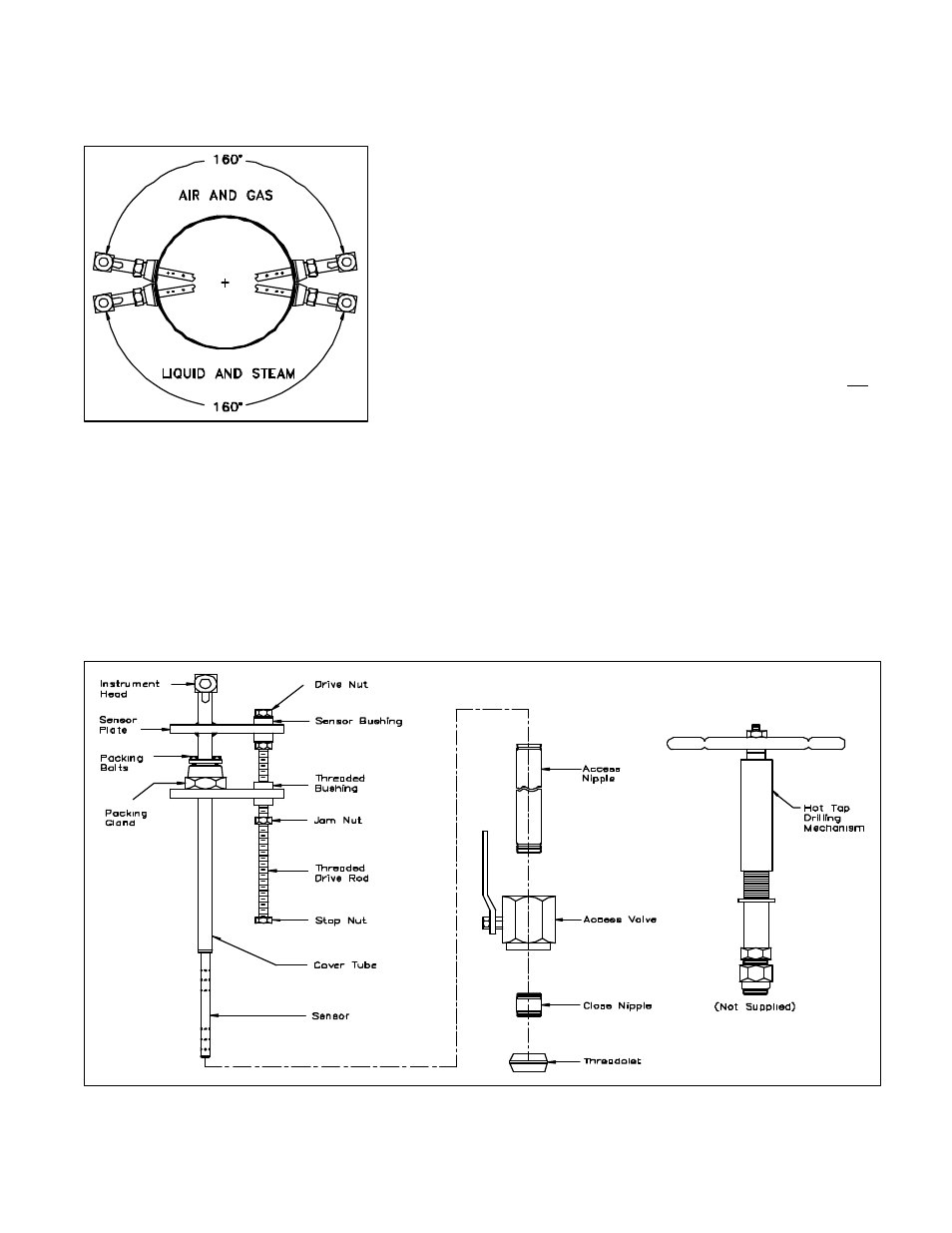

4.2.2 Vertical Piping

The Verabar may be mounted in any location around the

circumference of the pipe for vertical piping applications

(Figure 1).

Figure 1. Verabar Orientation in Horizontal Pipe

4.3

DP Transmitter/Local Indicator

Location

When choosing a Verabar location, consider the DP

transmitter/local indicator location:

•

The transmitter must be mounted below the

Verabar for liquid and steam applications.

•

The transmitter must be mounted above the

Verabar for air and gas applications.

4.4

Installation Drawings and Bill of

Materials

Additional information is available in the Installation

Drawings and Bill of Materials VB-7061 (also on the

VeraData CD). It contains standard and alternate

transmitter locations and a complete bill of materials

based on the fluid type and sensor orientation on the

pipe.

4.5

Piping Support

For sensors that extend more than 36” (915mm) beyond

the pipe wall or for sensors mounted in thin-walled pipes,

external support of the Verabar is recommended. This

will reduce stresses on the pipe wall.

5.0

INSTALLATION PROCEDURE

5.1

Assemble the Verabar

Your Verabar is shipped loosely assembled and is not

properly tightened for proper pressure retention. Follow

all assembly steps to ensure a safe installation (see

Figure 2).

5.2

Install Instrument Valves or Manifold

5.2.1 Valves

If the Verabar does not have a valve head, install

instrument valves using proper thread sealant. Be sure

instrument shut-off valves are installed and shut prior to

repressurizing the pipe.

5.2.2 Manifold

If the Verabar has a direct or integral manifold, be sure

the high and low pressure block valves are shut off prior

to repressurizing the pipe.

Figure 2. Verabar Model V200S (Single Rod)