Ordering information – Veris Verabar V200 Spec Sheet User Manual

Page 3

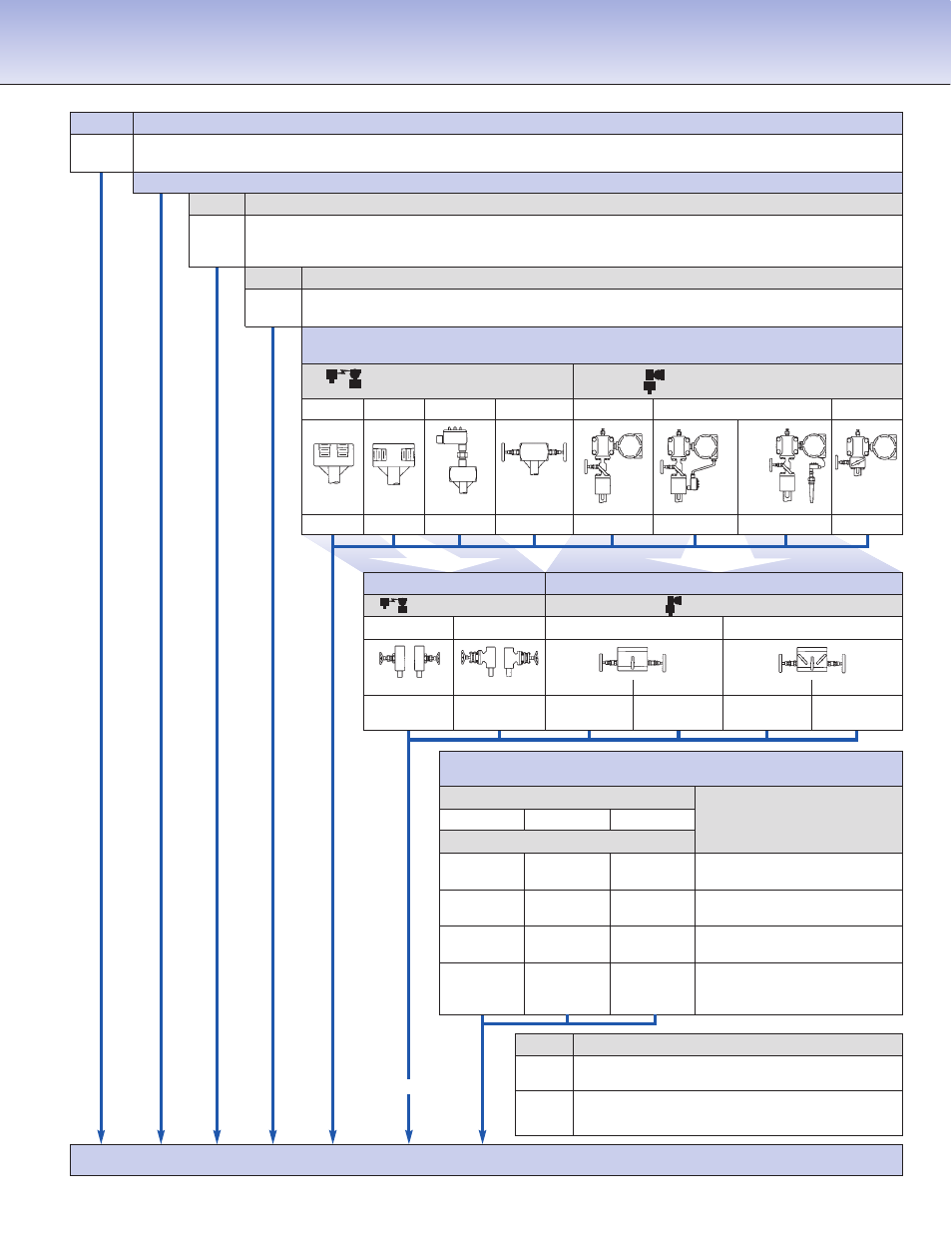

Model

Hot Tap • Threaded Pipe Connections and Components

V200S

Single Rod, Insert/Retract, General Purpose (05 Class 600#, 10 and 15 Class 150#)

V200D

Double Rod, Insert/Retract, Higher Pressures (600# max.) (10 and 15 only)

Pipe Size and Schedule or Exact ID and Wall Thickness

Code Sensor Pipe Size Range

05

2” to 6” (50mm to 150mm)

10

6” to 42” (150mm to 1050mm)

15

12” to 60” (300mm to 1500mm)

Code Pipe Orientation

H

Horizontal

V

Vertical

Instrument Connections

(Select Remote or Direct Mount)

(Transmitter sold separately)

Remote Mount Transmitter

Direct Mount Transmitter

(1/2” NPT)

(Flanged 450°F/232°C Max.)†

Parallel

Regular

RTD

*

Valve

Transmount

Mass Transmount

*

Manifold

P

R

D

T

F

G

E

M

Mounting Assembly — Select Valve Type & Material

(Includes valve, close nipple & weld coupling)

Sensor

(Valve Size NPT)

05 (3/4”)

10 (1-1/4”)

15 (2”)

Type, Material & Rating

Code

B3B

B5B

B8B

Ball, Brz., 600 psig @ 100°F,

100 psig @ 400°F (max.)

B3C

B5C

B8C

Ball, CS, 1000 psig @ 100°F,

100 psig @ 400°F (max.)

B3S

B5S

B8S

Ball, SS, 1000 psig @ 100°F,

100 psig @ 400°F (max.)

G3C

G5C

G8C

Gate, CS, ANSI Class 600#

G3S

G5S

G8S

Gate, SS, 1200 psig @ 100°F,

660 psig @ 800°F

Code

Options

SYN

Synchronized Two Rod Drive System

(Available for V200D-10 and V200D-15 sensors only)

SS Wetted Components

WPS

(Furnished with SS weld coupling, close & access nipple).

Must be ordered with SS access valve.

V200D 8”sch 40

10

H

R

C2NC

B5C

SYN

Typical Model Number

Ordering Information

Instrument Valves

(Opt.)

Manifolds

(Optional)

Remote Mount

Direct Mount

Needle

Gate

3-Valve

5-Valve

C2NC (CS)

C2GC (CS)

F3SC (CS)

F3HC (CS)

F5SC (CS)

F5HC (CS)

C2NS (SS)

C2GS (SS)

F3SS (SS)

F3HS (SS)

F5SS (SS)

F5HS (SS)

1/2” NPT

Soft Seat

Hard Seat

Soft Seat

Hard Seat

1/2” NPT

Explsn. Proof

Remote

RTD

Integral

RTD

Integral

Integral

Optional

*

For high pressure (>500psig) or high temperature (>500°F), remote mount RTD in a thermowell is preferred.

† Assuming adequate heat dissipation for transmitter.