Verabar, Hot tap models, Flow calculation – Veris Verabar V200 Spec Sheet User Manual

Page 2: Synchro-drive description, Synchro-drive benefits, Synchro-drive, Select model from page 3, Pipe or duct orientation, Enter flow conditions

Vera

bar

®

Vera

bar

Flow Calculation

Program

Flow Calculation

Program

5.

Flow Calculation

All Verabar applications require a flow calculation to verify

the DP, pressure and temperature limits, structural limits

and to size the transmitter. The Veracalc PC Program

is for use by representatives and end users. It is easy

to operate and includes steam tables.

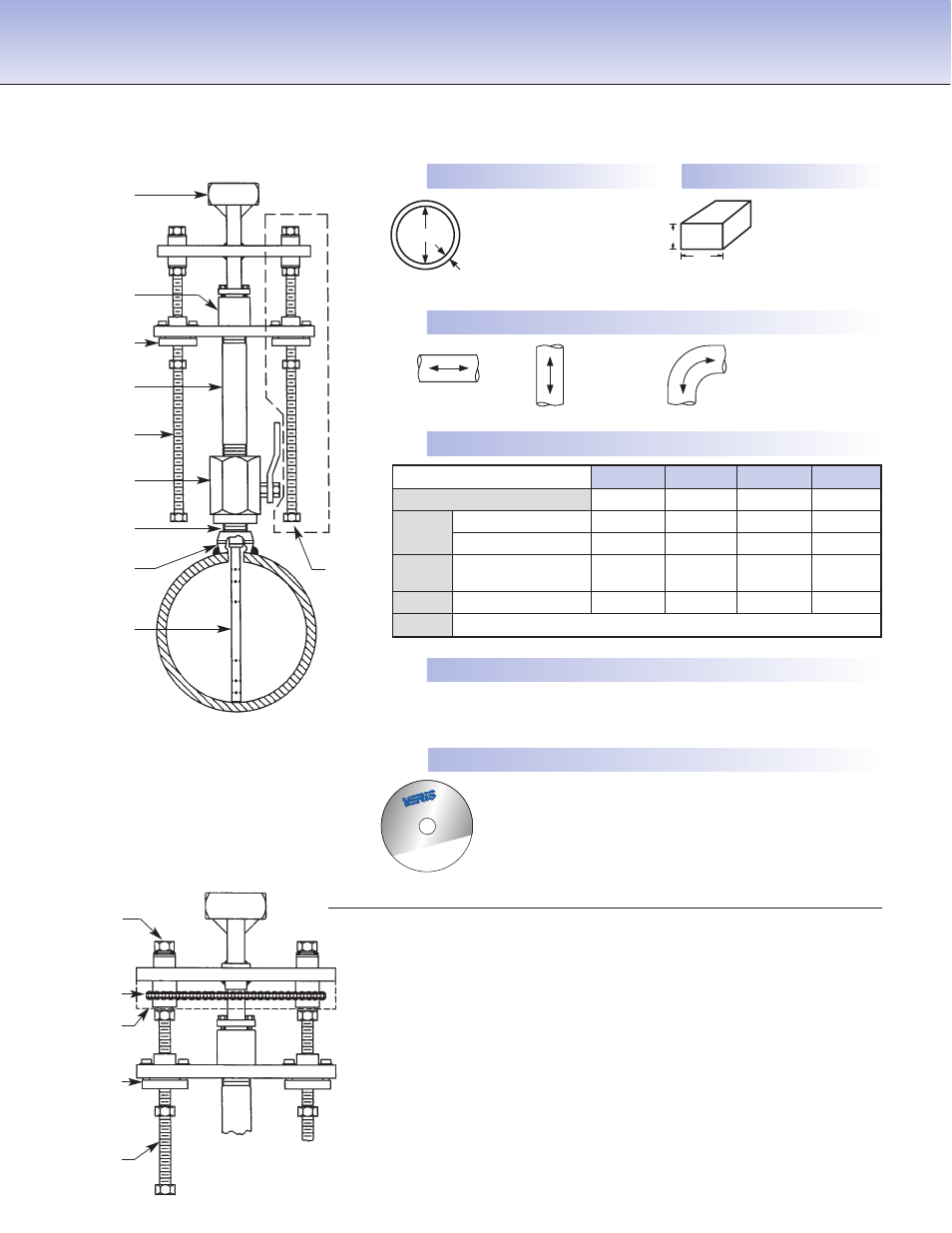

Synchro-Drive Description

• Designed for pressures greater than ANSI Class 150#, Synchro-Drive

is equipped with two drive rods that are coupled together by a

protected chain drive system. Turning either drive nut simultaneously

rotates both rods.

Synchro-Drive Benefits

• 95% faster and easier insertion and retraction.

• Equal load distribution over both rods maintains sensor alignment

and eliminates binding.

* U.S. Patent 5,410,920

V200S (Single Rod)

V200D (Double Rod)

Verabar

®

Hot Tap Models

Synchro-Drive

(Option SYN)

Drive nut

Drive chain

Drive rod

Anti-seize

orbital

bearing

Instrument

head (SS)

Anti-seize

orbital bearing

Packing gland

(SS)

Access nipple

(SS)

Access valve

(CS, SS or

BRZ)

Weld coupling

(CS) (SS-opt)

Close nipple

(SS)

Sensor (316SS)

V200D

only

Screw drive

(threaded

rod-SS)

Protective

chain shroud

4.

Select Model from Page 3

Use the Ordering Information table on Page 3 to determine your

model number.

Short

Straight Run

Consult Factory

(V) Vertical

(H) Horizontal

Pipe Size _____ Sch _____

Pipe ID _____ and

Wall _____ Pipe Mat’l _____

Wall

Height (H) _____

Width (W) _____

Wall _____

Duct Mat’l _____

Dimension

Verabar spans

(H) or (W)

Fluid Name:

Maximum

Normal

Minimum

Units

Flow Rate

All

Temperature @ Flow

Fluids

Pressure @ Flow

Gas

Specific Gravity, or

Molecular Weight

Liquid

Specific Gravity

Steam

Veracalc Program can calculate Density from Temperature and Pressure

ID

W

H

2.

Pipe or Duct Orientation

3.

Enter Flow Conditions

1.

Enter Pipe Dimensions or Duct Dimensions

Furnish the following information: