Spicer Ring Gear Nut & Bolt Torque Information User Manual

Spicer, Drive axles, Ring gear nut & bolt torque information – revised

Spicer

®

Drive Axles

P/N: SHAIS101I

Ring Gear Nut & Bolt Torque Information – Revised

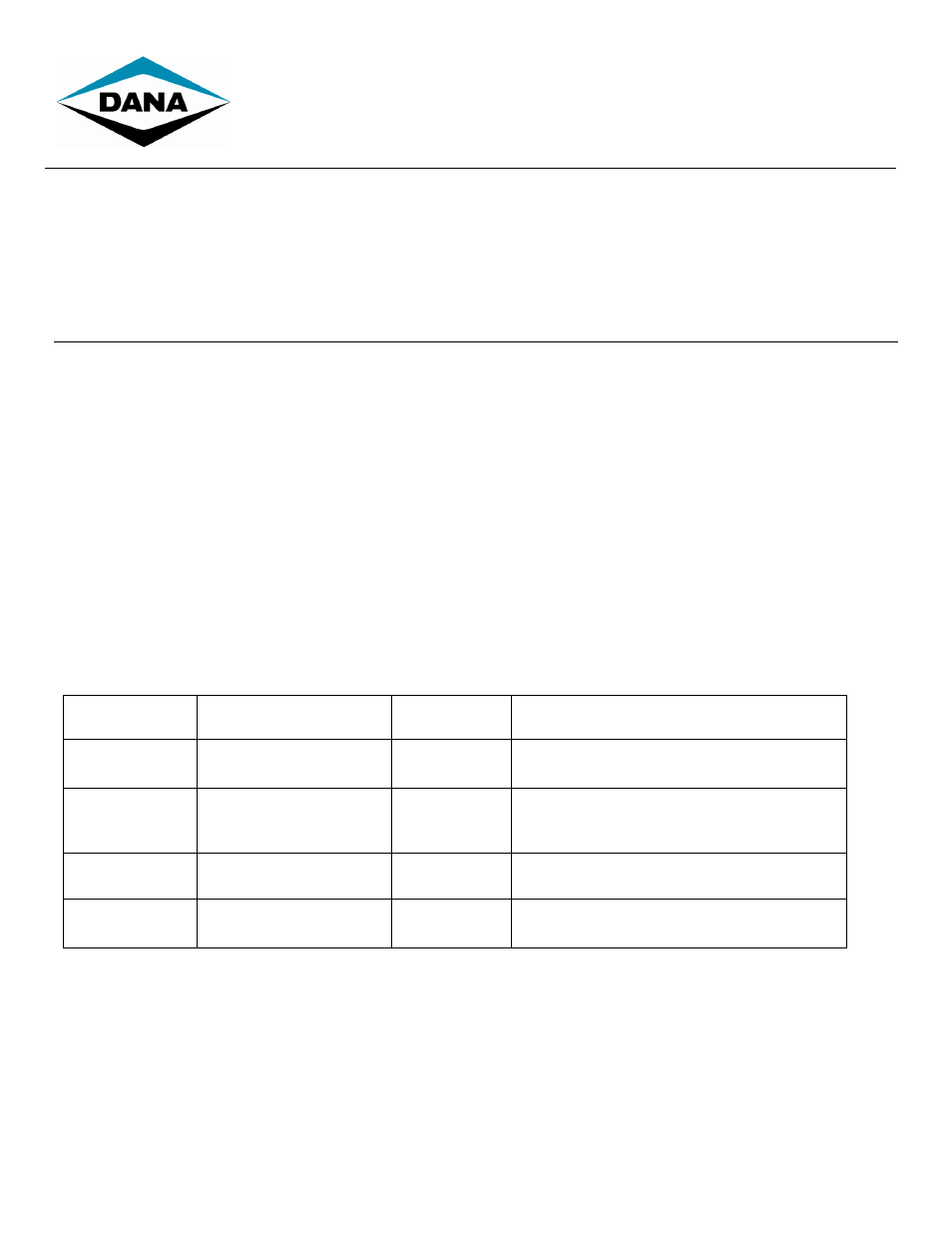

Listed below is important information pertaining to the installation of the ring gear bolts contained in this kit. Refer to the

chart below for specific model and torque information.

NOTE: FOR SOME RATIOS, ADDITIONAL TOOLING MAY BE REQUIRED TO PREVENT HEAD ROTATION DURING BOLT INSTALLATION

SPICER KIT

PART-NO.

MODELS

RING GEAR

BOLT SIZE

FULL TORQUE SPECIFICATION

360KY100 X

S135, S150 3.38 & UP

RATIOS ONLY

.625 – 18UNF

180-220 FT-LBS (244-298 N.m)

390KY100-X

(old# kit P/N was

401KY101 X)

“F”, “J” ALL RATIOS

“N” SERIES 3.06 THRU

6.14 RATIOS ONLY

M16 - 1.5 6G

300-320 FT-LBS (406-434 N.m)

057KY101 X

ALL “W” SERIES AXLES

M18 - 1.5 6G

300-320 FT-LBS (406-434 N.m)

300KY100 X

S230S

M18 - 1.5 6G

300-320 FT-LBS (406-434 N.m)

Copyright Dana Limited, 2013

Dana Aftermarket Group

SHAIS101I FEB 2013

All Rights Reserved.

P.O. Box 321

Printed in U.S.A.

Dana Limited

Toledo, OH 43697-0321

1. Examine the ring gear-mounting surface for any high spots after rivet removal.

2. Remove any high spots that appear. Clean the differential case and ring gear-mounting surface.

3. Place the ring gear on the differential case and install the bolts into the gear tooth side of the ring gear.

4. Apply Loctite-277 Threadlocker onto the bolt threads.

5. Install the flat washer and nut onto the differential case side.

6. When all fasteners have been installed, tighten bolts opposite one another in an even, “two step”

torque process until one half of the prescribed torque is obtained. Repeat the process to full torque

specifications as detailed in the chart below.

CAUTION:

OVER TORQUE OF THE BOLTS MAY CAUSE DAMAGE TO THE DIFFERENTIAL CASE, RING GEAR OR

FASTENERS. RING GEAR BOLTS HAVE A CLEARANCE FIT IN THE DIFFERENTIAL CASE AND RING GEAR

MOUNTING HOLES, WHICH REQUIRE CORRECT TORQUE TO ENSURE PROPER CLAMP!