Spicer Single Drive Axles Service Manual: S135L, S135N, S135S, S150L, S150N, S150S User Manual

Page 20

16

Pinion Assembly

Pinion bearing preload spacers are available in the

following thicknesses 0.286"-0.315" (7.26-8.00

mm). Refer to S135/S150 service parts booklet for

kits of commonly used preload spacers.

Always measure each spacer before assembly to

ensure correct thickness.

Note: Closer adjustment can be made by sanding the next

thicker spacer to desired thickness using emery cloth on

a flat surface.

CAUTION: Wash spacer thoroughly of emery cuttings

before installing on pinion.

10. Repeat process until torque to rotate is between

10-40 lbs. in. After proper preload is achieved,

remove yoke and install new seal with proper service

tool.

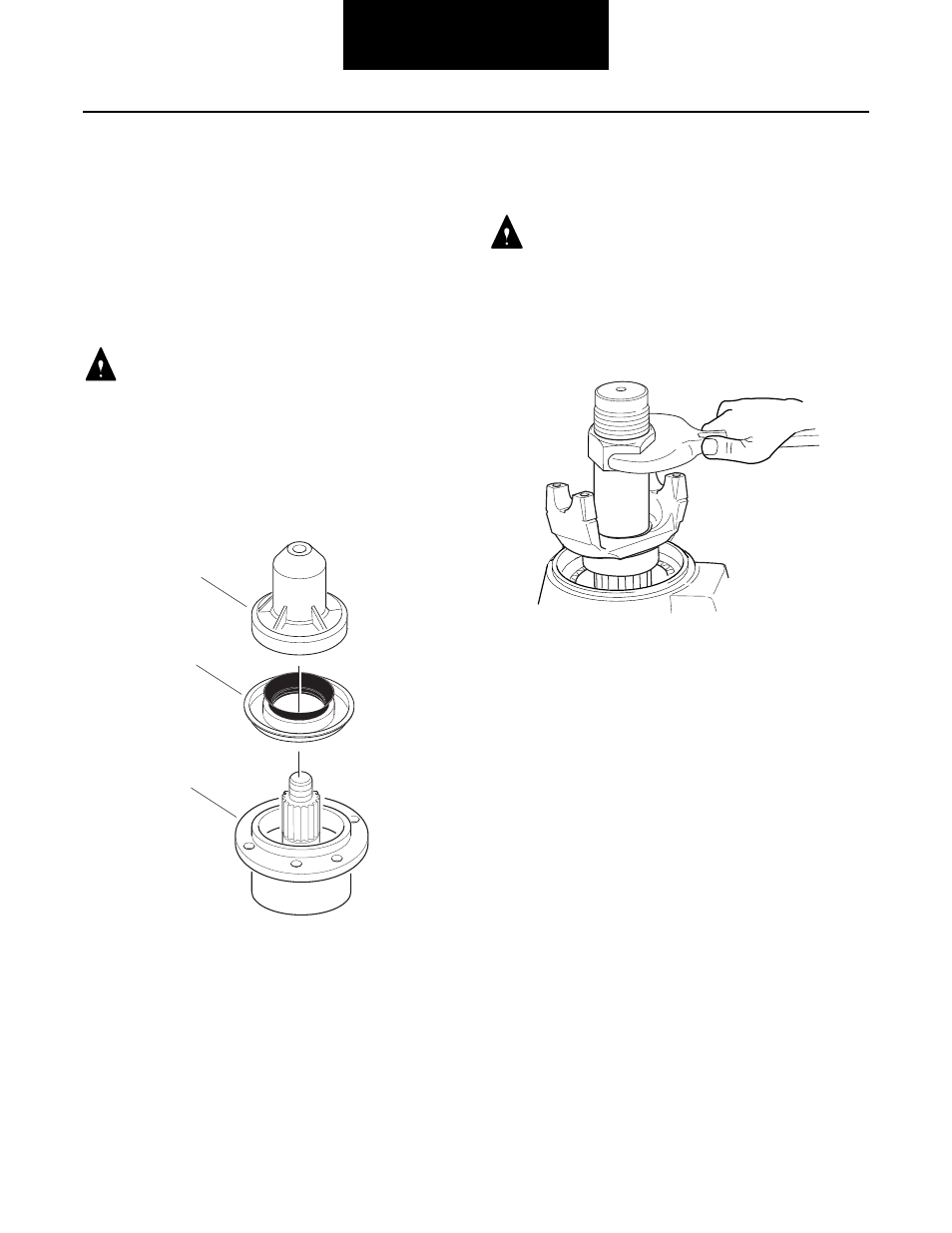

11. Install pinion oil seal with proper service tool.

(Acceptable torque to rotate is 15-45 lbs. in. when

pinion seal is installed.)

Note: Dana strongly recommends using seal drivers when

installing new seals. Use the proper driver to ensure the

seal is square and installed to the proper depth.

CAUTION: Oil seals can be easily damaged prior to

installation. Use care when handling the new seal to pre-

vent damage or contamination. Leave the seal in its

package until installation. On new yokes, leave the pro-

tector on the yoke until it is installed on the shaft to pre-

vent damage or contamination.

12. Install end yoke using yoke installer service tool

DST1009.

Note: Spicer recommends that new torque prevailing nuts be

used.

13. Apply Loctite 680 (green) to threads.

14. Use torque multiplier and torque pinion nut to

700-900 lbs. ft. (950-1,220 N•m).

3

2

1

1 - Tool

2 - Seal

3 - Pinion bearing cage