Spicer Lubrication Specifications Universal Joints User Manual

Page 6

Recommended Relube Cycles for Universal Joint Kits

Relubrication cycles vary depending on the service requirements and operating conditions of the equipment. Chart 4

shows a recommended lube cycle for various types of service.

Lubrication Procedure for 10 Series Slip Assemblies

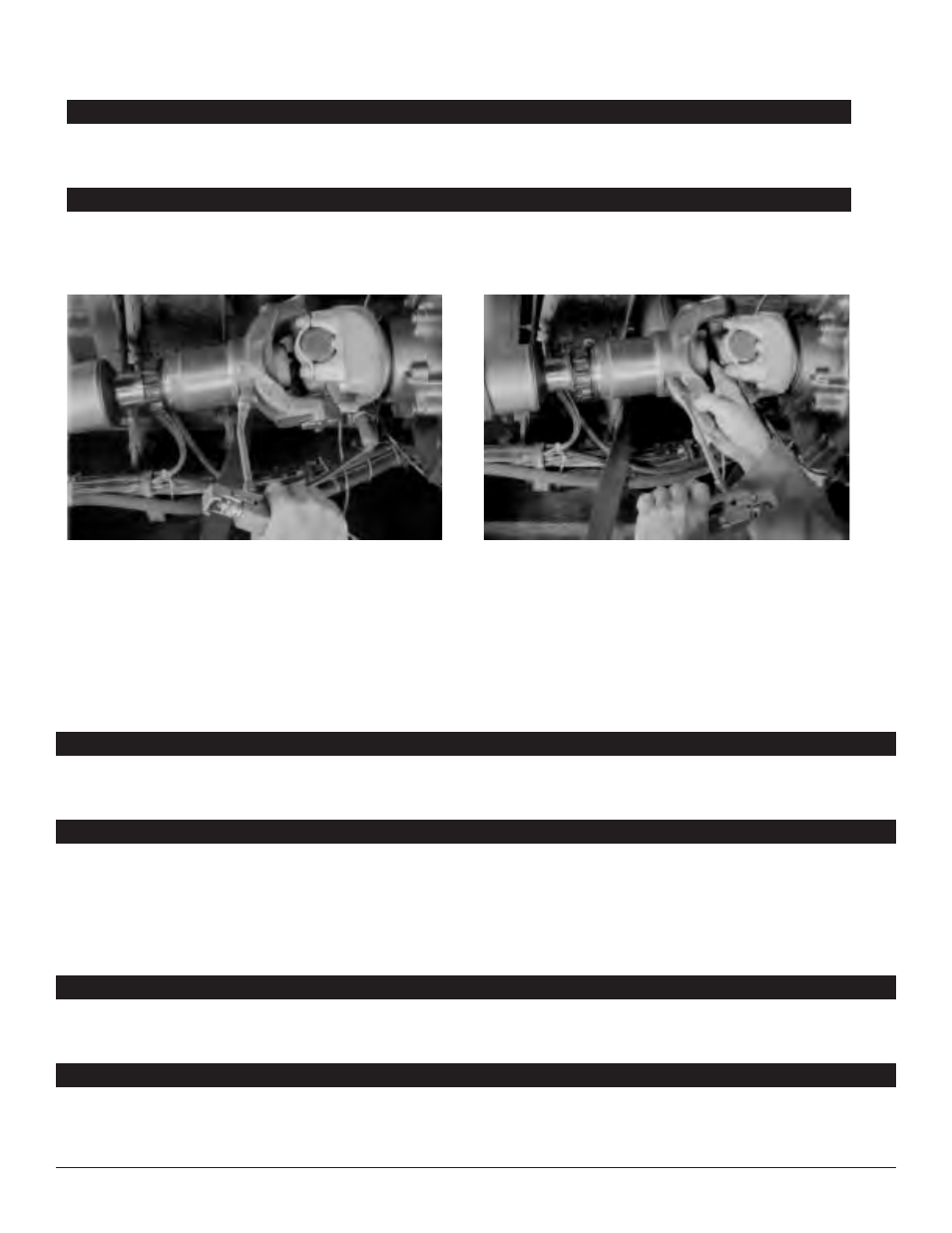

Relube slip assemblies at the same intervals as universal joint kits. Apply grease gun pressure until grease

appears at the pressure relief hole in the slip yoke plug. (See Photo 2)

Cover the hole in the plug with your finger and continue pres-sure until grease appears at the slip yoke seal. (See Photo 3)

Photo 3

Photo 2

Important - In cold winter months, activate the slip spline assembly by driving the vehicle sufficiently to cause

displacement of the grease prior to its stiffening. Otherwise, the slip yoke plug may be forced out due to hydraulic pressure

causing loss of grease and allowing abrasive contaminants to enter the slip spline.

The SPL slip assemblies are lube for life and do not require greasing. Any damage to the boot or loss of a boot clamp will

require the old boot to be removed and a new boot kit installed. Follow the proper procedure for cleaning the yoke shaft and

slip sleeve before adding new grease. This procedure can be found in service manual 3264-SPL. Note: The boot kits have

the proper amount of grease in every kit, it is not necessary to add additional grease.

Recommended Lubricants for Slip Assemblies

Always use a good E.P. grease, meeting N.L.G.I. Grade 2 specifications, on Glidecoat™ and steel splines. The same

lubricant used for universal joint kits is satisfactory for slip assemblies.

Lubrication Procedure for Non Self-Aligning Center Bearing Assemblies

Initial lubrication is done by Spicer manufacturers. (No attempt should be made to add or change grease within the bearing

itself.) However, when servicing a driveshaft in the field with a new center bearing, it is necessary to fill the entire cavity

around the bearing with waterproof grease to shield the bearing from water and contaminants. The quantity should be

sufficient to fill the cavity to the extreme edge of the slinger surrounding the bearing.

Lubricants must be waterproof. See Recommended Lubricants for Center Bearings, below.

Lubrication Procedure for Self-Aligning “XC” Center Bearing Assemblies

The XC self aligning center bearing does not require any lubrication within the bearing or to the bearing outer surface due

to the maintenance-free double lip seal bearing.

Recommended Lubricants for Center Bearings

Rylon Premium No. 3

Source: Amoco Oil Company

Amolith 8516

Source: Amoco Oil Company

Van Talgar No. 4

Source: Exxon Company

© Dana Limited 2008