Wheel end lubrication procedure – Spicer Lubrication Manual - July 2012 User Manual

Page 17

Wheel End

Wheel End Lubrication Procedure

Before operating the axle, the wheel hub cavities and

bearings must be lubricated to prevent failure.

When wheel ends are serviced, follow Dana’s wheel end

lubrication procedure before operating the axle.

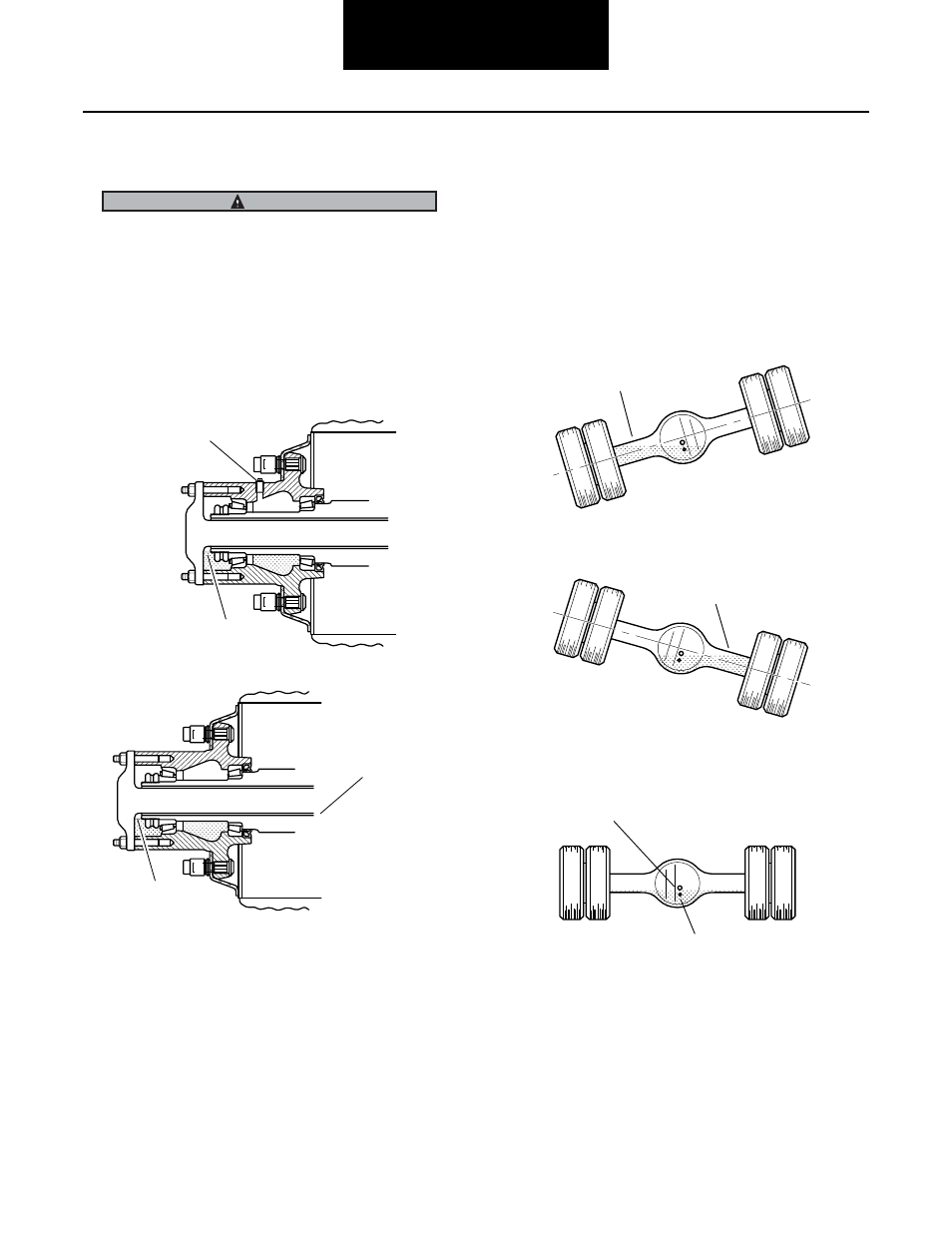

Spicer axles may be equipped with either of two wheel end

designs:

•

Wheel ends with an oil fill hole

•

Wheel ends without an oil fill hole

Wheel End Lubrication Procedure

(with oil fill hole)

1. Rotate the wheel end hub until the oil fill hole is up.

2. Remove the oil fill plug.

3. Pour 0.5 pint [0.2 liter] of axle sump lubricant into

each hub through the wheel end fill hole.

4. Install oil fill plug and tighten to specified torque.

Wheel End Lubrication Procedure (without oil fill

hole)

1. With axle level and wheel ends assembled, add

lubricant through filler hole in axle housing cover

until fluid is level with the bottom of filler hole.

2. Raise the left side of the axle 6 in. [152 mm] or

more. Hold axle in this position for one minute.

3. Raise the right side of the axle 6 in. [152 mm] or

more. Hold axle in this position for one minute.

4. With axle on a level surface, add lubricant through

housing cover oil filler hole until fluid is level with

the bottom of the hole.

Note: Axles without wheel end fill holes require approxi-

mately 2.5 pints [1.2 liters] of additional lubricant to

bring the lubricant level even with the bottom of the fill

hole.

CAUTION

Wheel end oil fill hole

Proper lubricant level

Lubricant flow from sump

Proper lubricant level

Oil will run into Wheel End

Oil will run into Wheel End

Fill Housing with oil to bottom of Plug

Temperature Sensor Mounting Hole

17