Handle the heaviest loads and longest hauls, The right driveshaft for any application, Always working to keep you moving – Spicer Life Series Driveshafts Brochure User Manual

Page 2: Compare models and see the difference, Spicer life xl, U-joints, Advanced features. superior performance, Trust the experts

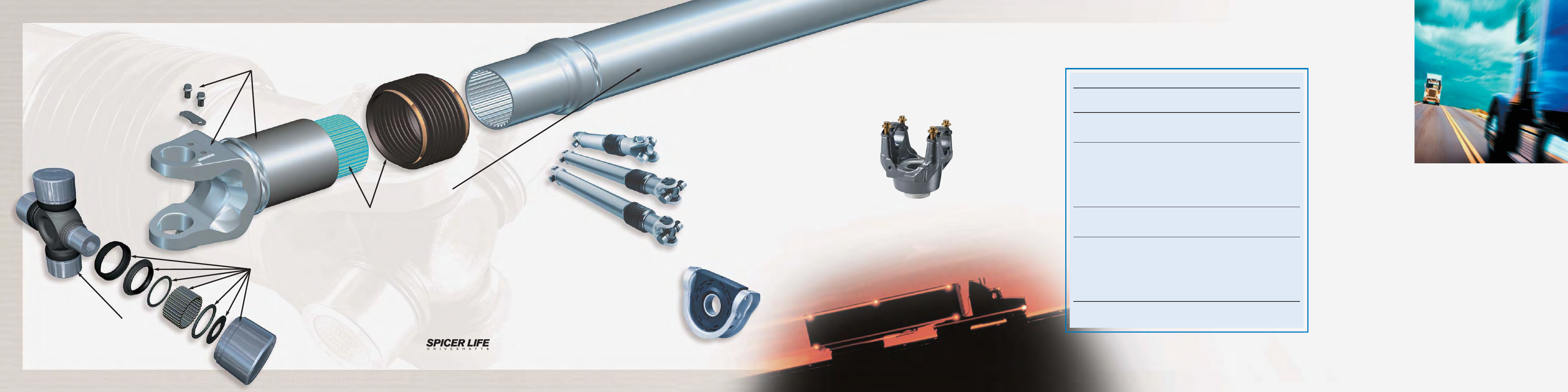

Features Quick Disconnect

™

end

yokes with cold-formed bearing

retainers that act as a structural

member. This results in controlled

deflection, improved overall

strength, anti-rotation, and

easier maintenance.

Patented and compact

spring tab design reduces

looseness in the driveshaft

system that can contribute

to unwanted vibration.

Dana’s Spicer Life XL

®

u-joint has been engineered

for reduced wear and longer

service life. Features 350,000

mile initial relubrication.

Thrust washers eliminate

metal-to-metal contact.

This prevents wear and

end galling, and lowers the

overall operating temperature

of the u-joint kit.

Multi-lip seals on the

u-joints incorporate a garter

spring, seal guard, and a

needle spacer for extended

lubrication intervals.

Increase balance, strength,

and torsional stiffness – for

maximum component life

and minimum vibration –

with the Glidecoat

®

slip

spline and Hytrel

®

boot.

Permanently lubricated

slip member protects against

environmental contaminants

and eliminates maintenance.

Protecting the permanently

lubricated slip member is a

Hytrel

®

boot. The durability of

this boot has been verified by

both laboratory testing and

years of real-world use.

Hytrel

®

is a registered trademark

of DuPont.

Leaner and meaner describes

the increased driveshaft

tube diameter and decreased

wall thickness – unlike

typical driveshafts. You enjoy

higher critical speeds and

increased strength, without

increased weight.

Your wheels will always

be turning – at unsurpassed

efficiency – thanks to Spicer Life

Series

®

driveshafts and Spicer Life XL

®

u-joints. As the world leader in driveshafts

and related components, Dana is always

moving forward with innovative solutions.

Innovation:

With Dana,

the Wheels

Are Always

Turning

Handling heavy loads over

the long haul has never been

easier or more efficient,

thanks to Dana’s Spicer Life

Series driveshafts – which have

set the standard for heavy-duty

driveshaft performance.

Spicer Life Series driveshafts

take our industry standard 10

Series

™

one better. Innovatively

designed for demanding, high

torque and high horsepower

applications, they’re compatible

with today’s electronically

controlled engines and lower

axle ratios.

And while Spicer Life XL

u-joints may be greased, they

also offer extended initial

lubrication intervals for linehaul

applications of up to three

years or 350,000 miles,

whichever comes first. This all

adds up to trouble-free, long-

life driveshaft performance –

even when hauling heavier

loads and multiple trailer

configurations.

At Dana, we’re committed to

continually advancing driveline

technology in all types of

vehicles, all around the world.

Better performance. Longer

life. Lower operating costs.

We’ve set the standard – so

you can enjoy the advantages!

Always Working to Keep You Moving

Handle the Heaviest

Loads and Longest Hauls

Spicer Life XL

®

U-Joints

Standard Spicer Life XL

®

u-joints on the Spicer Life

Series

®

driveshafts allow for

even greater performance, with

lower maintenance, reduced

lifetime operating costs, and

decreased vehicle downtime.

Every component has been

engineered to give you a

longer, smoother ride.

Advanced Features.

Superior Performance.

With our significant bearing

design improvements, you’ll

notice a difference in the way

your trucks perform.

Seals on the Spicer Life XL

u-joints incorporate multi-lip

seals, a garter spring, an

advanced seal guard, and a

needle spacer for extended

lubrication intervals.

Trust the Experts.

Spicer

®

is a name known around

the world for innovations in

driveshaft technology. Nobody

works harder to reduce

operating costs, cut downtime,

and improve the resale value

of your vehicles.

When you want the best

in driveshaft technology,

you want Spicer.

The Right Driveshaft for Any Application

Compare Models and See the Difference

Torque Slip

Bearing

Linehaul

Rating

Swing

Member

Tube

Cup

Lube

Weight

2

Series

(lbs. ft.) Dia. (in.)

Seal

Size (in.)

Seal

Interval*

Warranty

1

(lbs.)

1760

12,200

8.38

Sliding

4.09 x .180

Single Lip

10,000 mi.

1 year or

95.0

Seal

with Slinger or 3 mo.

100,000 mi.

(whichever

comes first).

SPL-170 XL

12,550

7.60

Boot

4.96 x .118

Multi-Lip

Initial at

Matches

90.7

with Garter 350,000 mi.

OEM warranty

Spring and

or 3 yrs.

period of up

Seal Guard (whichever

to 3 yrs. or

comes first).

350,000 mi.

Relube every

100,000 mi./

6 months

thereafter.

1810

16,500

9.00

Sliding

4.59 x .180

Single Lip

10,000 mi.

1 year or

117.4

Seal

with Slinger or 3 mo.

100,000 mi.

(whichever

comes first).

SPL-250 XL 18,450

7.60

Boot

5.06 x .167

Multi-Lip

Initial at

Matches

103.5

with Garter 350,000 mi.

OEM warranty

Spring and or 3 yrs.

period of up

Seal Guard (whichever

to 3 yrs. or

comes first). 350,000 mi.

Relube every

100,000 mi./

6 months

thereafter.

NOTES

* Linehaul (on-highway) applications. Intervals vary by application.

1

Check OEM stated warranties for information. Dana matches the vehicle manufacturers’ warranty period up to this limit.

2

Weights based upon a 70" driveshaft center-to-center length.

Features Quick Disconnect

™

end

yokes with cold-formed bearing

retainers that act as a structural

member. This results in reduced

deflection, improved overall

strength, anti-rotation, and

easier maintenance.

The innovative design of the new Spicer

®

XC

™

center bearing simplifies installation and alignment

of driveshaft assemblies, while providing improved

reliability and durability.

The new Spicer XC center bearing reduces bracket

complexity and is fully interchangeable with the previous

center bearing design. The lighter design also features a

permanently lubricated bearing with improved sealing

and upgraded rubber cushions, eliminating the need for

slingers for improved performance and less downtime.

The elastomer isolator system maintains optimal

performance with mounting angle fluctuations of ±10°,

ensuring the driveline system is correctly aligned and

operating smoothly and efficiently.

®