Spicer, Tpcs, Tire pressure control system) – Spicer TPCS (Tire Pressure Control System) User Manual

Page 2: System components

Spicer

®

TPCS

(Tire Pressure Control System)

All applications must be approved by the Application Engineering Department. Specifications and/or design are subject to change without notice or obligation.

Printed in USA ACSL-0004 08/07

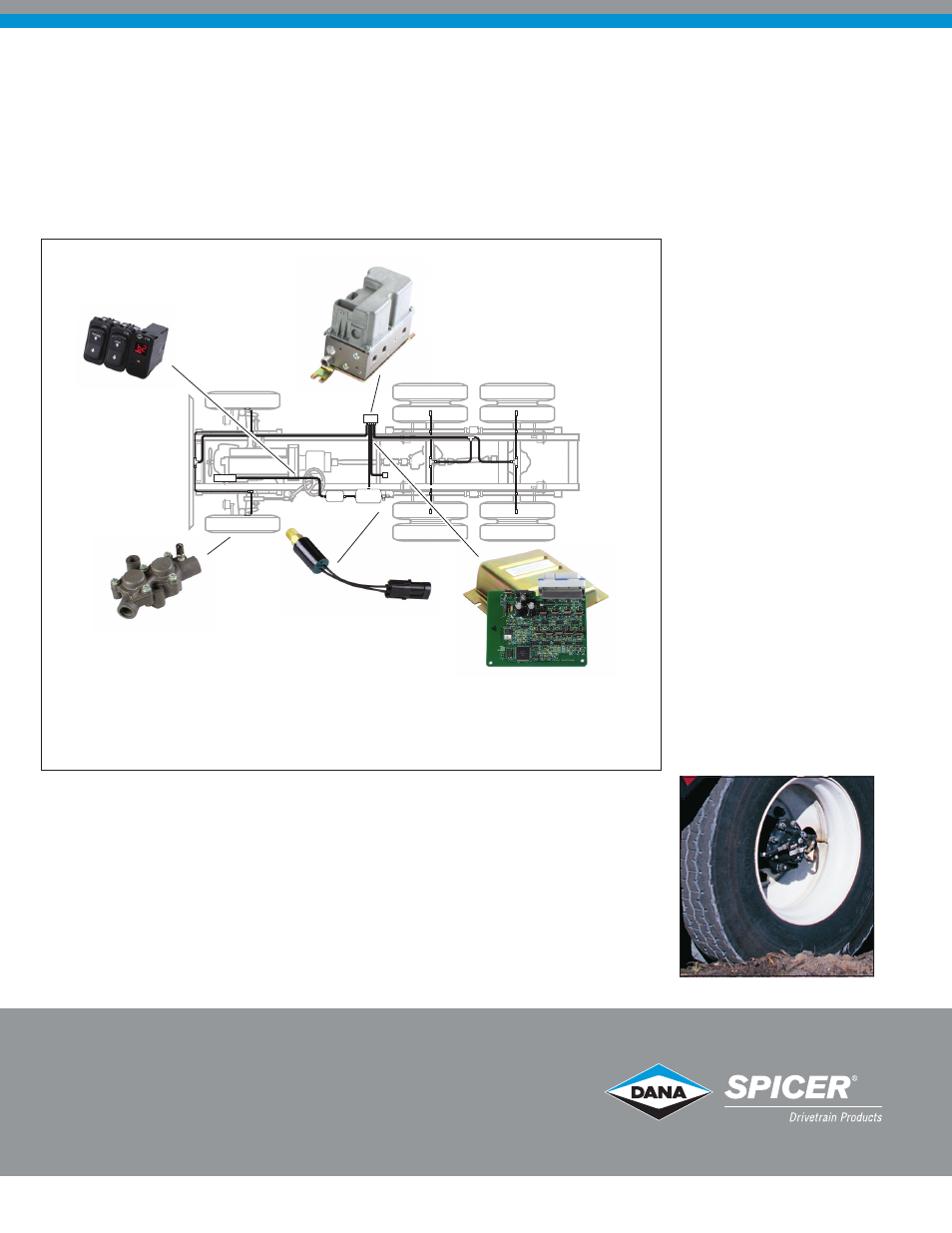

System Components

The Right Tire Pressure. For the Right Surface. Right on Demand.

Flexibility was a key factor in designing the Spicer

®

Tire Pressure Control System. Its two

modes – Loaded and Unloaded – together with its three terrain settings, give you six

pressures to let you operate effectively across a wide variety of terrain. “Highway” mode

allows for high speed travel on paved surfaces, “Off-Highway” permits operation on unpaved

surfaces, and “Emergency” provides extremely low tire pressures to help free a stuck

vehicle, or take on grades and other extreme conditions that previously were impossible

to negotiate without assistance.

Available from all major

truck manufacturers.

Spicer

®

TPCS is the only

factory-installed system

available, and it’savailable on

a wide range of heavy truck

models and configurations.

TPCS takes air from the

same compressor supplying

the brakes and other on-

board systems. TPCS uses a

series of electro-pneumatic

controls, feeding air to the

wheel ends as required to

regulate tire pressures.

Steer, drive, and even trailer

axle pressures can be con-

trolled using the system.

Most tandem drive axles

(40,000 – 52,000 lbs.)

and single drive axles

(21,000 – 26,000 lbs.)

can be configured to work

with TPCS.

Wet

Tank

Air

Dryer

PCU

Wheel Valves

• Normally closed design isolates tires

in the event of tire puncture or hose failure

• Prevents tire pressure leak-down

automatically when parked

• No need for separate shut-off valves

Pressure Switch

• Electronic brake priority ensures air brake

supply pressure is optimized

• Suspends TPCS operation until air brake supply

is fully charged

Electronic Control Unit

• Micro-processor based control center receives

driver input from the DDM

• Option to communicate to the drive train to optimize

vehicle performance

• Supports industry standard diagnostic tools

Operator Input

• Rocker switches and

Driver Display Module (DDM)

provide operator interface

• Supports 3 terrain and 2 load

selections

• Built-in diagnostic messaging

Pneumatic Control Unit

• Solenoid-controlled manifold receives

electrical commands from the ECU

• Controls wheel valves to inflate, deflate or measure

tire pressures by axle group

• Pressurizes the system only during inflate/deflate

cycles, extending air seal life

No external air lines.

All rotating seals are

internally mounted for

reliable operation.

For spec‘ing or service assistance, call 1-877-777-5360 or visit our website at www.dana.com

Dana Commercial Vehicle Products Group

3939 Technology Drive

Maumee, Ohio, USA 43537

www.dana.com