Spicer 2007 Spicer Driveshafts Service Manual User Manual

Page 15

13

Lubrication

Lubrication

Quick Disconnect™ (Half Round) Universal Joints

1.

If any of the bearing assemblies fail to purge removal

of the driveshaft is necessary. See the original-

equipment manufacturer for proper driveshaft

removal procedures.

2.

Place the driveshaft in v-blocks and apply a C-clamp

across the half round bearings. Apply grease gun

pressure. Completely purge both bearings.

3.

If outboard bearings fail to purge, slightly loosen C-

clamp and reapply grease gun pressure until both

half round bearings purge.

4.

After all four bearings purge fresh grease, re-tighten

the C-clamp to squeeze out excess grease and wipe

clean. This will ease installation of universal joint kit

back into yoke. Install universal joint kit in the yoke

using new straps and bolts, and torque bolts to the

required specifications. Reference bolt torque speci-

fications in the above table.

5.

If the bearings still will not purge, complete removal

of the universal joint kit is needed to determine the

cause of blockage. Refer to original-equipment man-

ufacturer's service manual for removal procedures.

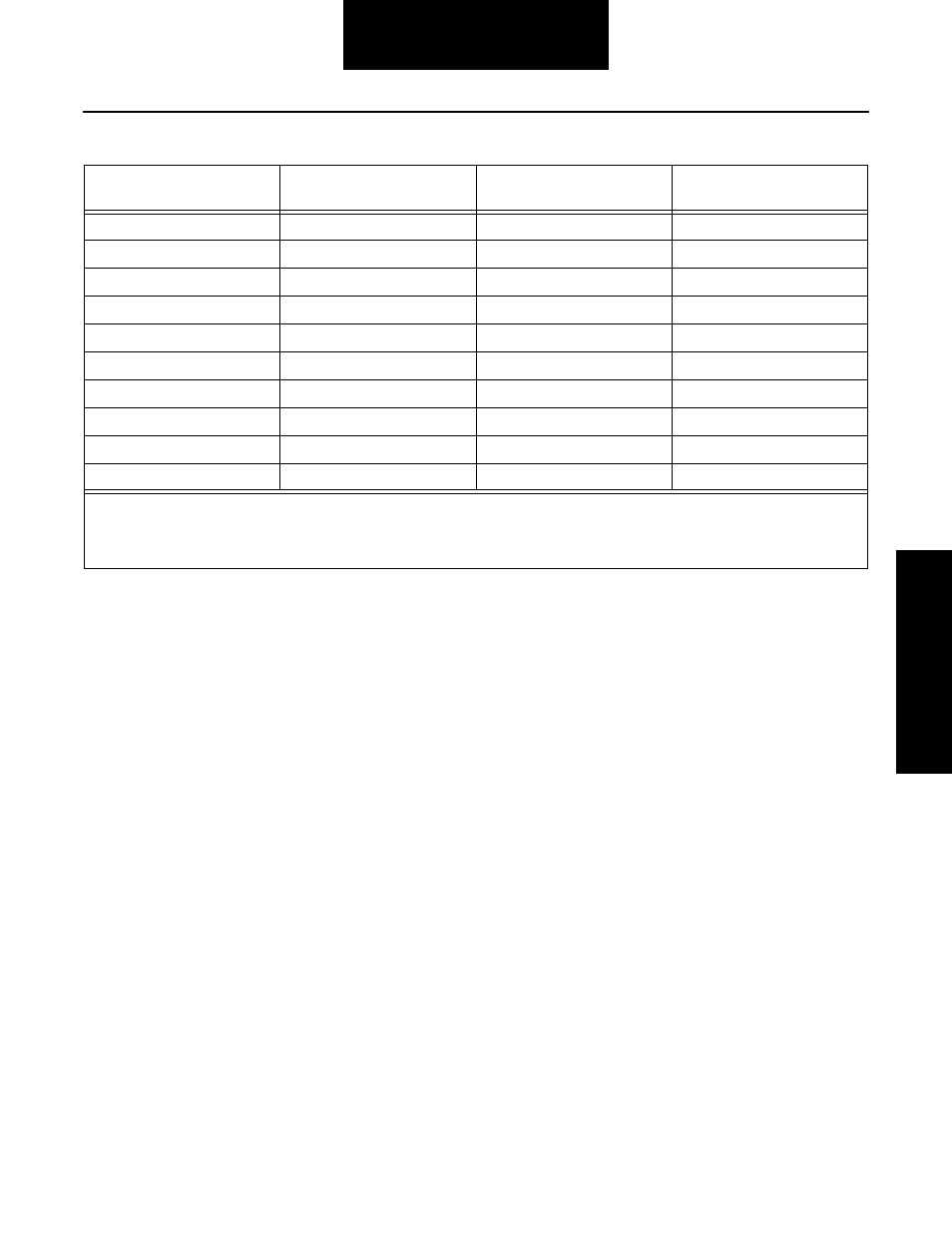

Series

Strap Kit

Assemblies

Recommended

Bolt Torque

N•m

1310

2-70-18X

13-18 lbs. ft.

17.6 - 24.4

1330

2-70-18X

13-18 lbs. ft.

17.6 - 24.4

1350

3-70-18X

30-35 lbs. ft.

40.7 - 46.5

1410

3-70-18X

30-35 lbs. ft.

40.7 - 46.5

1480

3-70-28X

45-60 lbs. ft.

61 - 81.3

1550

3-70-28X

45-60 lbs. ft.

61 - 81.3

1610

5-70-28X

45-60 lbs. ft.

61 - 81.3

1710

6.5-70-18X

115-135 lbs. ft.

162.7 - 183

1760

6.5-70-18X

115-135 lbs. ft.

162.7 - 183

1810

6.5-70-18X

115-135 lbs. ft.

162.7 - 183

The bolt torque specifications refer to Spicer bearing straps and bearing plates only. If using original-equipment bearing straps

and bearing plates, refer to manufacturer’s service manual for proper bolt torque specifications.

Note: Unless otherwise noted all recommended bolt torques are with dry threads.