High Lifter Outlaw Clutch Kit for Polaris 700 Sportsman (02-04) Non-EFI User Manual

Page 2

6. It is a good idea to clean your clutches. Using a clean rag and a contact/brake cleaner that DOES NOT leave an oily

film or residue, clean all areas of the clutch except on the bushings. Cleaning the clutch bushings with a cleaning

solvent can cause premature wear. This applies to both clutches.

7. Install the WHITE colored primary spring. Make sure the spring fits flat into the clutch at both ends. Install the

cover plate making sure the “X” lines up. Tighten the six outside cover bolts evenly so the cover goes on straight to

prevent bushing damage. Install the center clutch bolt and torque to 45-47 ft./lbs. After riding your machine, if

you would like LOWER engagement than where this kit engages, you can install the RED colored spring. This

spring will LOWER your engagement 3-400 rpms. If your kit only has one primary spring you can order this

optional spring through EPI.

8. Remove the secondary (rear) clutch by removing the center clutch bolt and pulling towards you. The clutch should

slide off the splined shaft. If the clutch sticks on the shaft spray some penetrating fluid on the shaft to help free it.

If it still doesn’t come off, you will need to order a secondary clutch puller available through EPI. When the clutch

does come off pay attention to the shims behind the clutch on the shaft. These shims effect the clutch alignment, if

they slide off the shaft be sure to put them back on.

9. Place the clutch face down so the snap ring is facing up. Make sure you remove the back snap ring only, if you can

see the back side of the helix you have the correct side. Push down on the helix to take the pressure off the snap

ring and remove the snap ring. The helix and spring can now be taken out of the clutch. CAUTION the helix will

have spring tension on it and can pop up and out of the clutch when snap ring is removed.

10. Apply a thin layer of grease on the splined hub of the EPI helix. Install the BLACK colored secondary spring.

Align the helix on the splined shaft and compress about halfway down. Make sure that when you push the helix into

the clutch you do not damage the three plastic rollers, if needed you can rotate the clutch either direction to gain

clearance. Push the helix down, place the factory washer on the shaft so it will sit under the snap ring. Install the

snap ring. If you can not compress the helix far enough to install the snap ring it is ok to remove the washer and

run without if needed.

11. If you removed both clutches from the machine it is easiest to install both clutches and the belt at the same time.

To install both clutches and the belt place the belt in the secondary clutch so the numbers on the belt read from left

to right. Squeeze the belt at the opposite end of the clutch to force the belt to open the secondary clutch and slide

the belt down into the clutch OR you can LIGHTLY tap on the belt with a plastic or rubber hammer to force the belt

into the clutch. Place the primary clutch through the belt and slide both clutches onto the machine. If you did not

pull the primary clutch off, you will need to place the belt in the primary clutch and install the secondary clutch onto

machine. Place the belt as much as you can into the secondary clutch, starting at the top of the secondary. If you

can’t get the belt completely on rotate the clutch so the belt rotates on. Torque secondary clutch bolt to 15 ft./lbs.

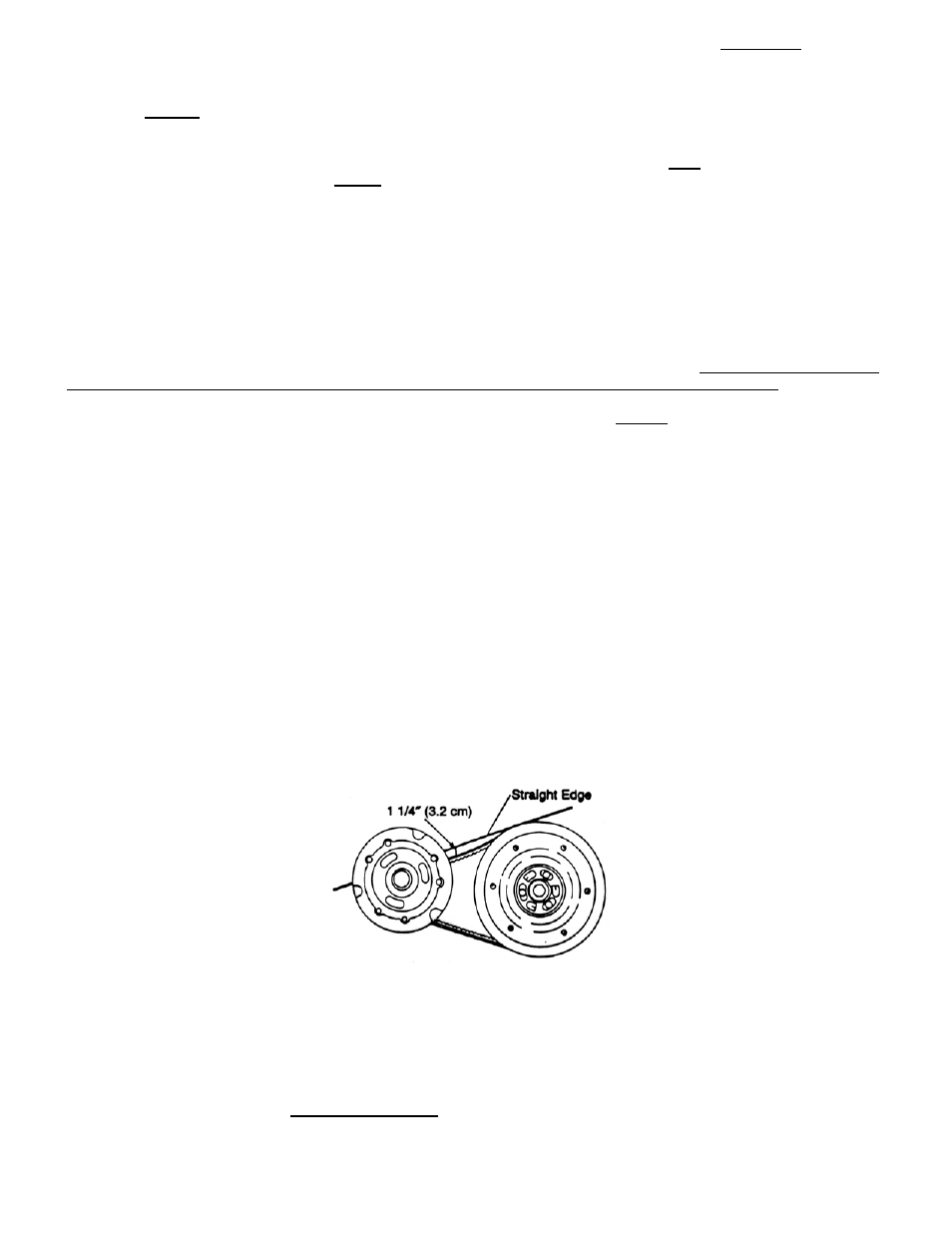

12. Check for proper belt deflection. The belt should ride 1/16” to 1/8” outside of the secondary clutch. Belt deflection

should be 1 1/8” to 1 1/4” between the clutches. Place a straight edge on top of the belt between the clutches.

Push down lightly on the belt to remove slack in the belt. Measure from the bottom of the straight edge to the top

of the belt (see diagram), this measurement is your belt deflection. If you belt is out of specification, you can

change it by adding or removing shims between the secondary clutch sheaves. Add shims to increase belt deflection

or remove shims to decrease belt deflection. One shim must always be between clutch sheaves at all times.

13. Install the plastic clutch cover making sure it seals properly. Install the small metal clip back onto the machine.

Tighten the zip ties or clamps to seal the vent tube on top of the clutch cover. Zip ties are included in the clutch kit

if they are required. Install the side panel and seat. Install the foot rest and prepare to ride.

14. If after riding the machine something doesn’t seem right, double check that the secondary clutch has been

assembled correctly.

NOTICE: Even with this clutch kit, you should be advised that using substantial throttle when the tires are not able to

spin can cause the belt to slip and damage may occur. EPI recommends that the transmission be shifted into low

range when high load, slower speed situations are encountered. EPI is not responsible for any damage to the drive

belt or any other original equipment component.