Operating instructions – RIDGID HC-300 User Manual

Page 13

HC-450/HC-300 Hole Cutting Tools

11

When using an extension cord, the GFCI on the

Hole Cutting Tool does not protect the extension

cord. If the outlet is not GFCI protected, it is ad-

visable to use a plug in type GFCI between the

outlet and the extension cord to reduce the risk

of shock if there is a fault in the extension cord.

Operating Instructions

WARNING

Always wear appropriate eye protection. Cutting

tools can break or shatter. Cutting produces chips

that can be thrown or fall into eyes.

Do not use for hot tapping. When cutting into an

existing system, the pipe must be drained and de-

pressurized prior to cutting. This reduces the risk of

electrical shock and other serious injury.

Do not wear gloves or loose clothing when operat-

ing machine. Keep Sleeves and jackets buttoned. Do

not reach across machine. Clothing can be caught

by the machine resulting in entanglement.

Keep fingers and hands away from rotating chuck

and saw. This reduces the risk of entanglement and

cutting injuries.

Follow operating instructions to reduce the risk of

injury from electrical shock entanglement, crush-

ing and other causes and prevent Hole Cutter dam-

age.

1. Confirm that the Hole Cutting Tool and work area

are properly set up and that the work area is free of

bystanders and other distractions.

2. Assume a proper operating position that will al-

low:

• Control of the Hole Cutting Tool, including the ON/

OFF switch and the feed handle. On the HC-300

you must be on the same side as the switch and

the feed handle. Do not turn the tool ON yet.

• Good balance. Be sure that you do not have to

over reach.

3. Move the ON/OFF switch to the ON position. Ob-

serve the rotation of the hole saw and pilot drill,

making sure it is running straight and true. If they

wobble, or any other issues are noted, move the

switch to OFF and unplug tool, fix any issues prior

to using. Keep fingers, hands and clothes away

from the turning chuck to help reduce the risk of

entanglement.

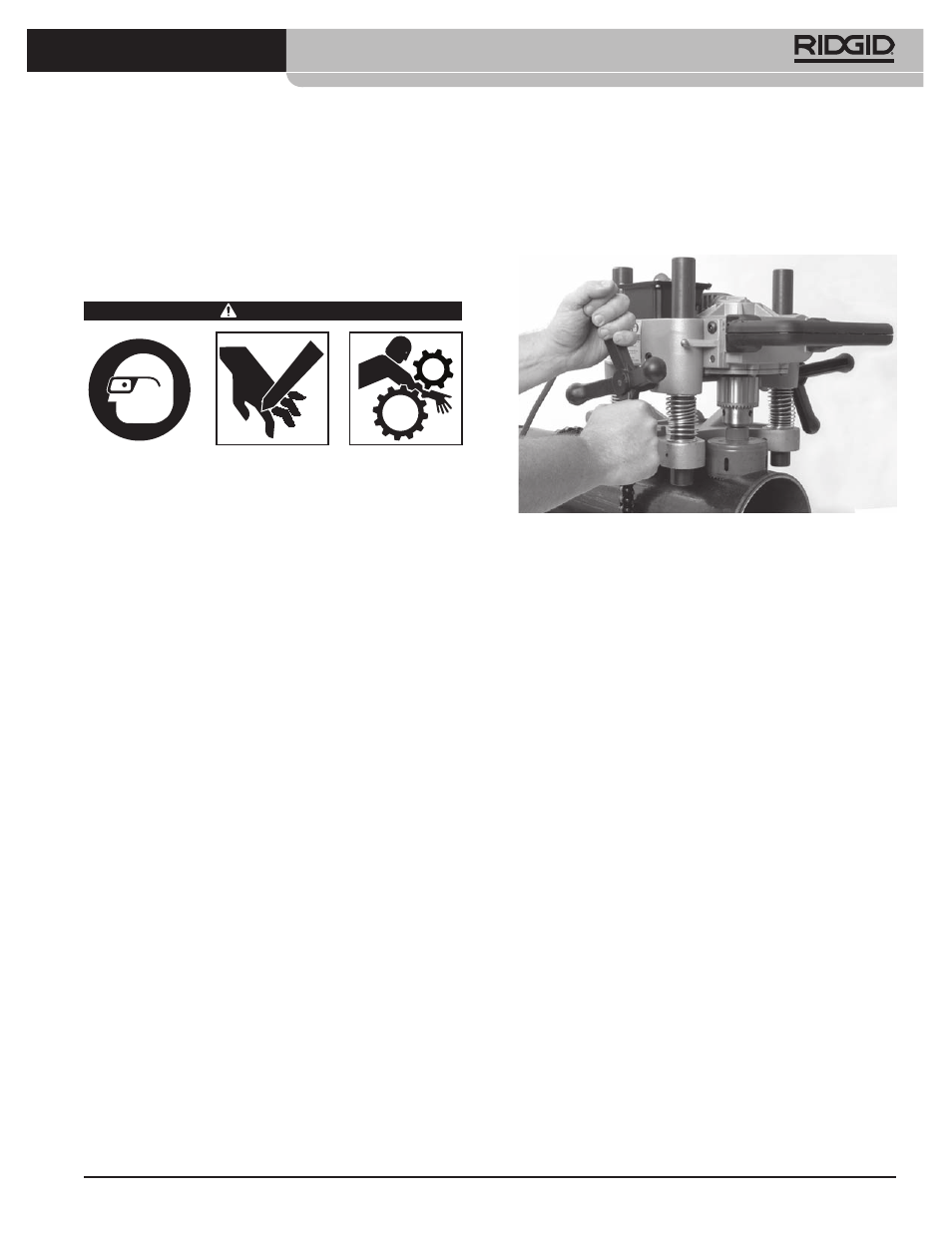

4. Place both hands on the hand wheel and advance

the pilot drill into contact with the pipe. Apply firm

pressure, and start drilling the pilot hole. Do not

force the pilot drill/hole saw. This can overload the

hole saw and the tool motor and cause premature

failure.

Once the hole saw is in contact with the pipe, con-

tinue to apply firm pressure. Depending on the

size and wall thickness of the pipe and the size of

the hole being cut, the hole saw may need to be

retracted slightly at times for chip removal.

If needed, the Hole Cutting Tool can be shut off and

a small amount of appropriate cutting lubricant

applied to the work piece. Do not apply lubricant

while the tool is running, this increases the risk of

entanglement. Take appropriate steps to prevent

the lubricant from dripping or being thrown dur-

ing use.

As the hole saw moves through the pipe and as the

cut is completed, there will be an interrupted cut

at times. Decrease pressure as this occurs to help

prevent jamming of the hole saw.

5. Once the hole is complete, retract the hole saw

from the pipe and turn the ON/OFF switch OFF.

6. Reverse the mounting procedure to remove the

Hole Cutting Tool from the pipe. Make sure you

have secure grip on the Hole Cutting Tool prior to

loosening the chain or pulling the plunger on the

HC-300.

7. If the pipe slug needs to be removed from the hole

saw, always make sure that the ON/OFF switch is in

the OFF position and the Hole Cutting Tool is un-

plugged before removing. Remove the slug with

care, the slug may be hot and edges can be sharp.

Figure 11 – Operating the Hole Cutting Tool