Installation instructions – RIDGID SLIDING LADDER RACK 250 User Manual

Page 3

Tools For The Professional

TM

SLIDING LADDER RACK

Ridge Tool Company

2

To reduce the risk of serious personal injury from the ladder falling or becoming a projectile during hard braking or a vehicle

accident:

• Read and follow all instructions and warnings before installing or using this product.

• The sliding ladder rack should only be used for transporting ladders. Never modify or use the sliding ladder rack for any

other purpose.

• Rack must be installed per instructions.

• Only mount the sliding ladder rack in a van, enclosed trailer, or metal truck cap.

• Maximum ladder weight should not exceed 36Kg

• When using power tools, follow tool manufacturer’s warnings and instructions.

• Protect your eyes. Wear safety goggles.

• Never install the sliding ladder rack system inside passenger compartments.

• Check for electrical wiring in areas where holes are to be drilled. Consult the vehicle’s shop manual for wiring paths.

INSTALLATION INSTRUCTIONS

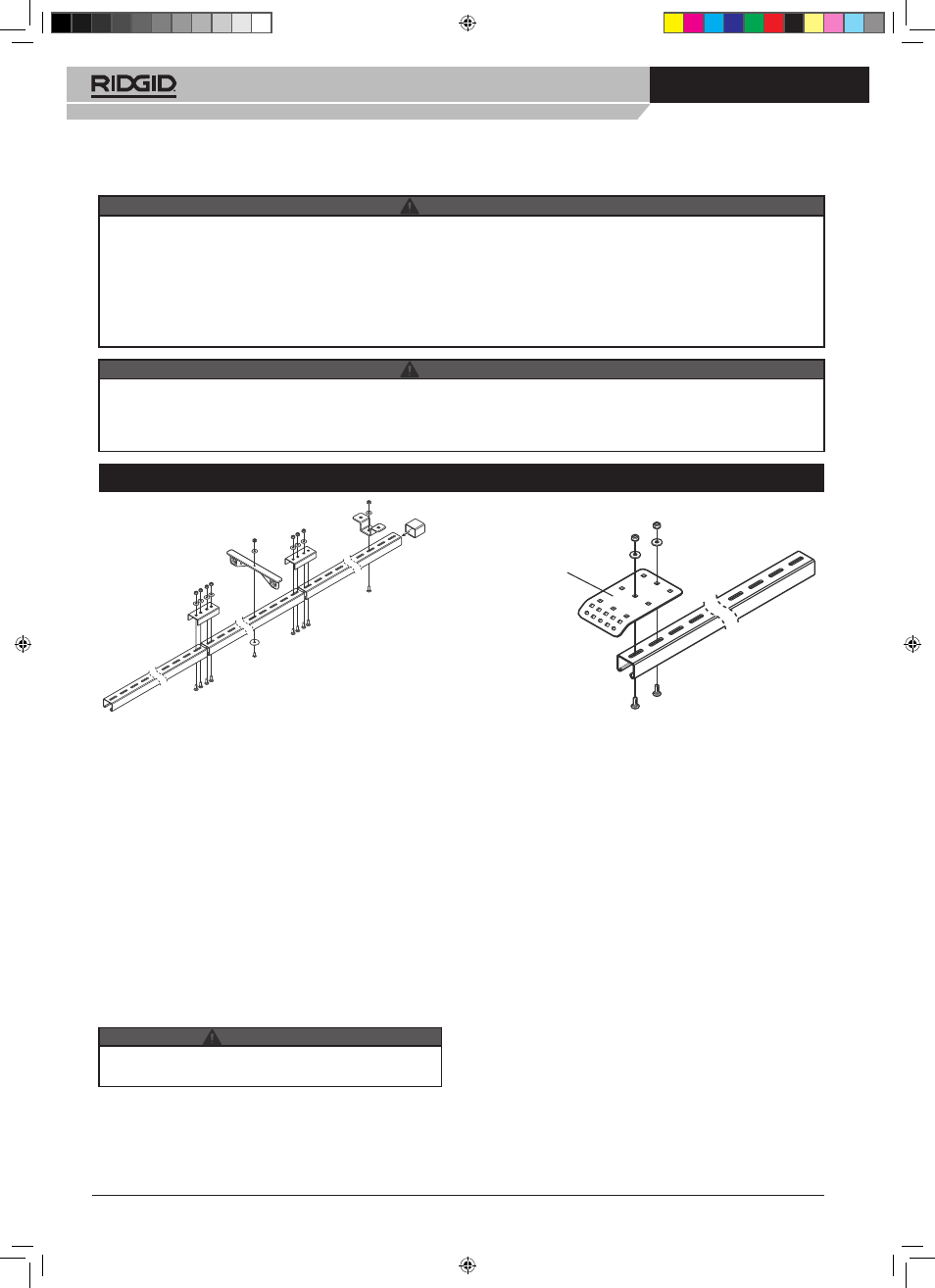

Step 1: RAIL ASSEMBLY INSTALLATION

Using connecting brackets (2), connect rail sections (3) us-

ing eight 1/4-20 x 3/4” carriage bolts, 1/4” flat washers and

1/4-20 nylon lock nuts.

NOTE: The installation instructions below are written for the

installation of this product to the roof ribs of a van or truck

cap. This rack can be mounted to the side wall of a trailer if

desired, using the same steps described below.

NOTE: Depending on the size and type of your vehicle, the

rail assembly may need to be cut to length for proper instal-

lation, Measure the distance inside the van, and cut the

assembled rail to the correct length.

Determine the rail mounting location inside vehicle (center,

offcenter, side). Measure the first three van rib locations

from the rear of the van, starting from the upper inside of

the rear door jamb, and measuring forward. Record those

dimensions.

• Rail assembly must be attached to all three roof ribs for

proper installation.

Fasten the rear mounting bracket to the rear of the rail

assembly(end opposite cut end) using two 1/4-20 x 3/4”

carriage bolts, 1/4” flat washers and 1/4-20 nylon lock nuts.

See Figure 1a.

From the rear of the rear mounting bracket, mark the rail

assembly at the recorded rib locations. Fasten a mounting

bracket just tight enough to be adjusted by hand, centered

at each mark, using one 1/4-20 x 3/4” carriage bolt, 1/4” flat

washer and 1/4-20 nylon lock nut each.

Place the rail assembly in the vehicle in position. Determine

whether the rear mounting bracket needs to be modified.

It may be offset to the rail assembly or have a portion of it

removed or the angle of the flange changed to meet the

door jamb flush, if necessary. Adjust the mounting bracket

locations on the rail assembly if necessary, to insure that

the mounting brackets can be properly fastened to the roof

ribs.

Remove the rail assembly from the roof ribs, and tighten the

mounting brackets securely.

Place the rail assembly back in position, and fasten it to the

roof ribs and rear door jamb with two 1/4-14 x 3/4” self drill-

ing screws and 1/4” flat washers per bracket.

Fasten the cord guide approximately 30” in from the rear of

the rail assembly, using a 1/4-20 x 7/8” pan head machine

screw, 1-1/4” OD washer, 1/4” flat washer and 1/4-20 nylon

lock nut. Adjust the 30” dimension for obstructions if neces-

sary.

Figure 1

Figure 1a

Rear

Mounting

Bracket

WARNING

WARNING

CAUTION

sliding_eng.indd 2

27/04/2009 11:04:03