Ab d, Compact electromagnetic drill press, Symbology – Milwaukee MDE 38 Compact User Manual

Page 4: Assembly

2

For additional safety instructions, read Safety Instruction book No. 58-13-0000.

Sound and Vibration information.

•

Typically the A-weighted sound pressure level of the tool is less than 88 dB (A). The noise level when working can exceed 101 dB (A). Wear ear

protection!

•

The typical weighted acceleration is less than 2,5 m/s

2

.

These declared values were obtained by laboratory type testing in compliance with the stated standards and are not adequate for use in risk

assessments. Values measured in individual work places may be higher than the declared values. The actual exposure values and risk of harm

experienced by an individual user are unique and depend upon the way the user works, the work piece and the workstation design, as well as upon

the exposure time and the physical condition of the user.

We, Milwaukee Electric Tool Corp., cannot be held liable for the consequences of using the declared values, instead of values reflecting the actual

exposure, in an individual risk assessment in a work place situation over which we have no control.

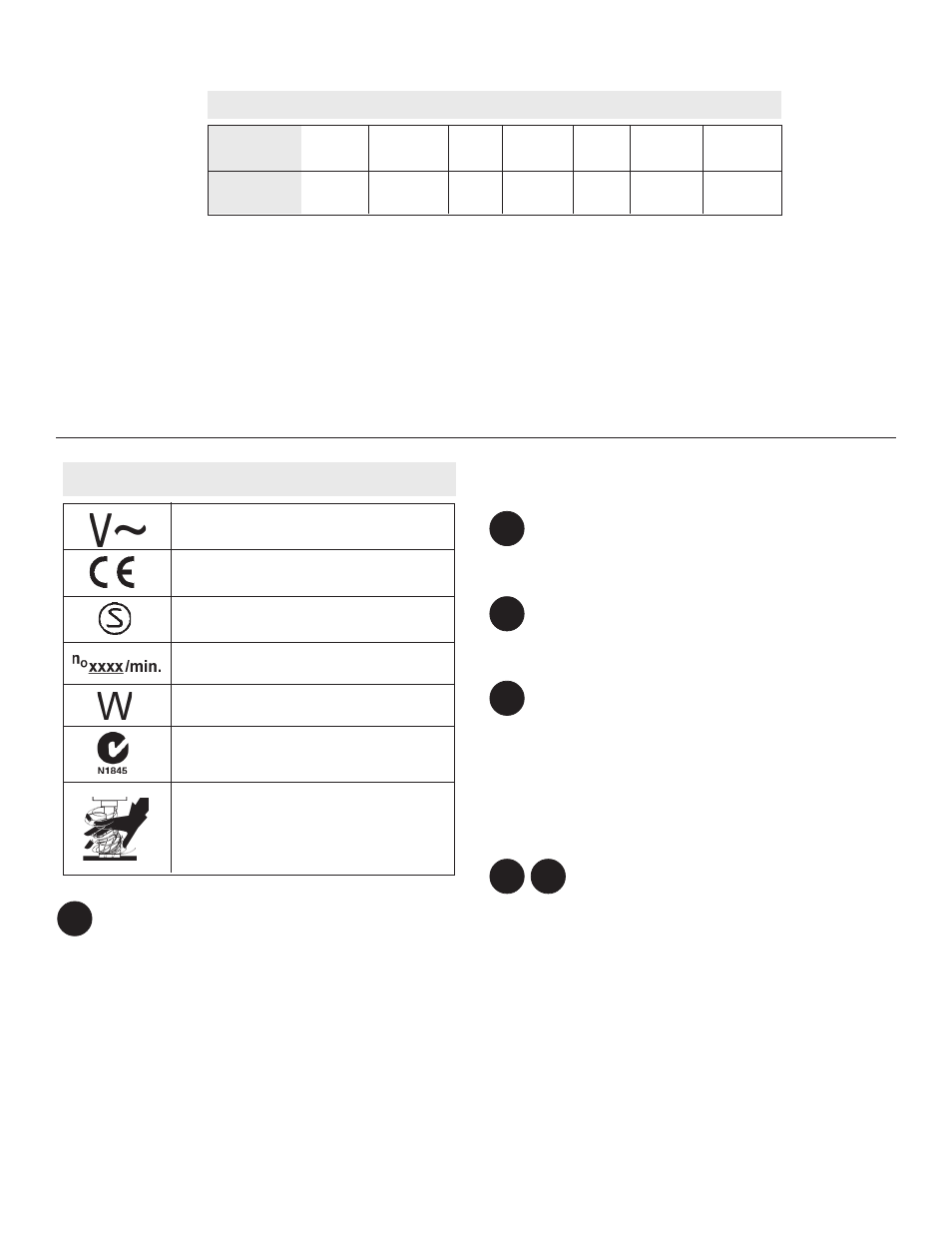

Compact Electromagnetic Drill Press

A

B

D

English

Alternating Current

Symbology

Watts

1050

Specifications

Arbor

Bore

19 mm

Article

No.

4270-50

No Load

RPM

450

Volts

AC

220-240

Catalog

No.

MDE 38

Compact

Assembly

Attaching Feed Handles and Grips

1.

Attach the feed handles and grips to the hub. Tighten securely.

2.

Mount the hub to either side by aligning the two (2) dowel pins on the

hub with the holes in the pinion. Tighten the handle screw.

Stop Knob

23 -

Stop knob

The stop knob stops the slide from moving. To install, screw the stop

knob into the location shown.

Adjusting the Gib Assembly

To adjust the gib, loosen or tighten the gib adjustment set screws on the

side of the housing accordingly with the 3/32" hex key provided.

Tightening the set screws increases friction on the slide. The gib should

be set tight enough to support the weight of the drill in any position. All

adjustment set screws should be set to provide smooth and even travel

over the entire length of slide movement.

The set screws contain a nylon patch that prevents them from moving

freely. Additional adjustment of the gib may be required over time with

extended use of the tool.

Adjusting the Support Bracket and Spacer for

Depth of Cut

24 - Spacer

25 - Support bracket

This unit is shipped from the factory set for 1" (25mm) depth cutters (Fig.

E). When using 2" (50mm) depth cutters, install the support bracket with

the spacer on bottom (Fig. F).

NOTE: Do not use a spacer and support bracket with a chuck adapter.

C

Twist

Drill

13 mm

HSS

Cutter

38 mm

1

-

Drill motor

2

-

Slide

3

-

Wrench storage

4

-

Stop knob

5

-

Pinion

6

-

Hub

7

-

Handle screw

8

-

Feed handle

9

-

Grip

10 -

Housing

11 -

Cord

DANGER! To reduce the risk of injury, always

keep hands, rags, clothing, etc. away from

moving parts and chips. Do not try to remove

chips while the cutter is rotating. Chips are

sharp and can pull objects into moving parts.

12 -

Safety strap

13 -

Magnetic base

14 -

Spacer

15 -

Drill spindle

16 -

Support bracket

17 -

Cutting fluid reservoir

18 -

Control panel

19 -

Magnet indicator light

20 -

Magnet switch

21 -

Drill on/off switch

22 -

Hand pump

E F

CE Conformity Mark

SEMKO Safety Mark

No Load Revolutions per Minute (RPM)

Watts

Australian C-tick Mark