Festool LEX 3 77-2-5 User Manual

Page 15

LEX 3

15

GB

requirements against electrical hazards cannot

be satisfied.

– Take good care of your tools. Keep the tools

sharp and clean to enable better and safer work.

Follow the maintenance regulations and the in-

formation about tool replacement. Keep handles

dry and free of oil and grease.

– Do not leave any tool key inserted. Before

switching on check that key and adjustment tools

are removed.

– Avoid unintended start-up. Do not carry a com-

pressed air tool that is connected to a com-

pressed air supply with your finger on the trigger.

When connecting the compressed air hose to a

compressed air supply, make sure that the switch

is not activated.

– Be alert! Pay attention to what you are doing. Al-

ways work with care.

Do not use the compressed air tool if you are not

able to concentrate properly.

– Have your compressed air tool repaired by a

qualified specialist.This compressed air tool cor-

responds to the relevant safety regulations. Re-

pairs should only be carried out by a qualified

specialist. The operator is otherwise at risk of an

accident.

– Only work with correctly processed compressed

air.

Using the Festool supply unit VE guarantees

this.

5.2

Other risks

In spite of compliance with all relevant design reg-

ulations, dangers may still present themselves

when the machine is operated, e.g.:

– Workpiece parts being thrown off,

– Parts of damaged tools being thrown off,

– Noise emissions,

– Dust emissions.

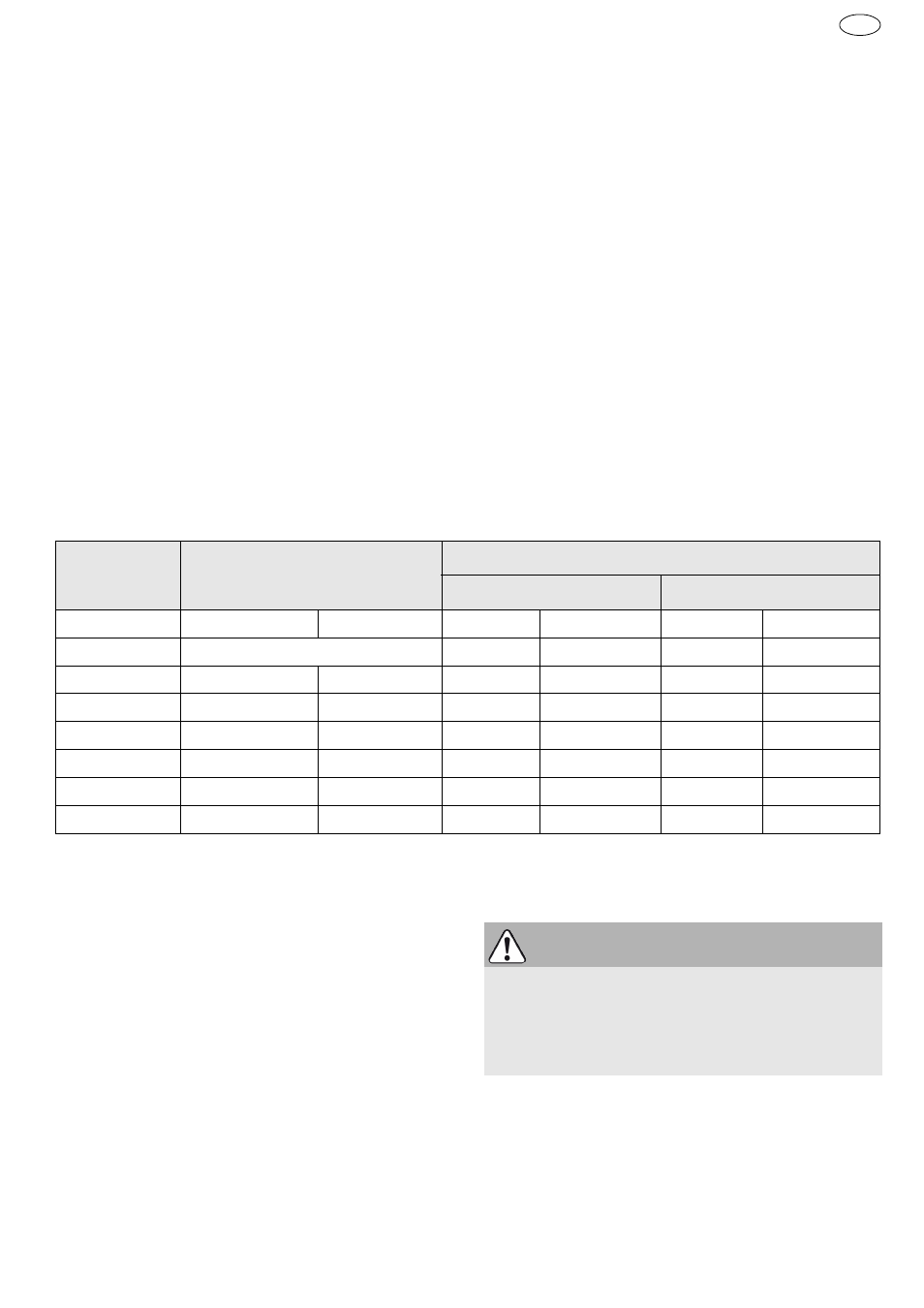

5.3

Emission levels

Levels determined in accordance with EN ISO 15744/ISO 28927 are typically:

The specified emissions values (vibration, noise)

– are used to compare machines.

– They are also used for making preliminary esti-

mates regarding vibration and noise loads during

operation.

– They represent the primary applications of the

power tool.

Increase possible for other applications, with other

insertion tools or if not maintained adequately. Take

note of idling and downtimes of machine!

6

Compressed-air supply and com-

missioning

6.1

Compressed air preparation

The machine is designed for lubricated and non-lu-

bricated operation.

The Festool service unit VE must be used in lubri-

cated operation. Consisting of a filter, control unit,

condensation drain and lubricator, the service unit

Version

Sound pressure level / Sound

power level

Vibration emission level

3 directions

1 direction

1

L

PFA

/ L

WA

Uncertainty

a

h

Uncertainty K

a

h

Uncertainty K

[dB(A)]

[m/s²]

[m/s²]

[m/s²]

[m/s²]

LEX 3 77/2,5

72 / 83

3

< 2,5

1,5

< 2,5

1,5

LEX 3 125/3

70 / 81

3

4,4

2,0

< 2,5

1,5

LEX 3 125/5

72 / 83

3

5,0

2,0

< 2,5

1,5

LEX 3 150/3

72 / 83

3

3,7

2,0

< 2,5

1,5

LEX 3 150/5

72 / 83

3

3,9

2,0

2,7

1,5

LEX 3 150/7

76 / 87

3

5,8

2,0

3,2

1,5

1.

For information: According to the old EN ISO 8662.

CAUTION

Risk of injury

Make sure that the pneumatic tool is switched

off when you connect the compressed-air sup-

ply.