Installation guide ccr3 controller – Danfoss CCR3 Controller User Manual

Page 7

Installation Guide

CCR3 Controller

77

Heating Solutions

VI.D3.A2.02

DEN-SMT/SI

No

LCD Display

BASIC MENu - FuNCtION DESCRIPtION

24

TRet (80)

.....

Required return temperature for measure supply temperature: 80 °C

Factory setting: 54 °C

25

TRet (90)

.....

Required return temperature for measure supply temperature: 90 °C

Factory setting: 58 °C

26

Shift1

..0 °C..

Shift return temperature valid for all setting points. It can be adjusted up and down. The lowest shift setting

is to 10 degrees (anti frost setting value).

Each riser can be adjusted individually, riser by riser (from 1 to 16)

Factory setting: 0 ºC; in range of ±10 °C

27

RiserNr

16

Number of risers used in the system: settings from: 1-16

If more than 16 risers: choose 16 and connect selected risers parallel using one actuator’s output for two risers

(for two actuators) (max additional 16 risers)

Factory setting: 16

28

Int.Time

…….

Integration time of the control signal (depend of actuators type). The shorter time, quicker temperature

changes (no stable regulation). The longer time slower reaction for temperature change (stable regulation).

Factory setting: 6 sec (for dedicated TWA-Z (NO) actuators); setting range 1-100

29

Prop.Fac

……

Control gain of control signal (depend on actuators type). The higher gain control the bigger valves reaction

(no stable regulation). The lower gain control weak reaction for temperature change (stable regulation).

Factory setting: 10 (for dedicated TWA-Z (NO) actuators); setting range 1-100

30

VType

…….

Type of control valves: normal open or normal closed

Option to choose: NO or NC

Factory setting: NO

31

VCharact

…….

Type of valves characteristic

Option to choose: Linear or Hyperbolic

Factory setting: Hyperbolic (setting for 24 VAC actuator)

32

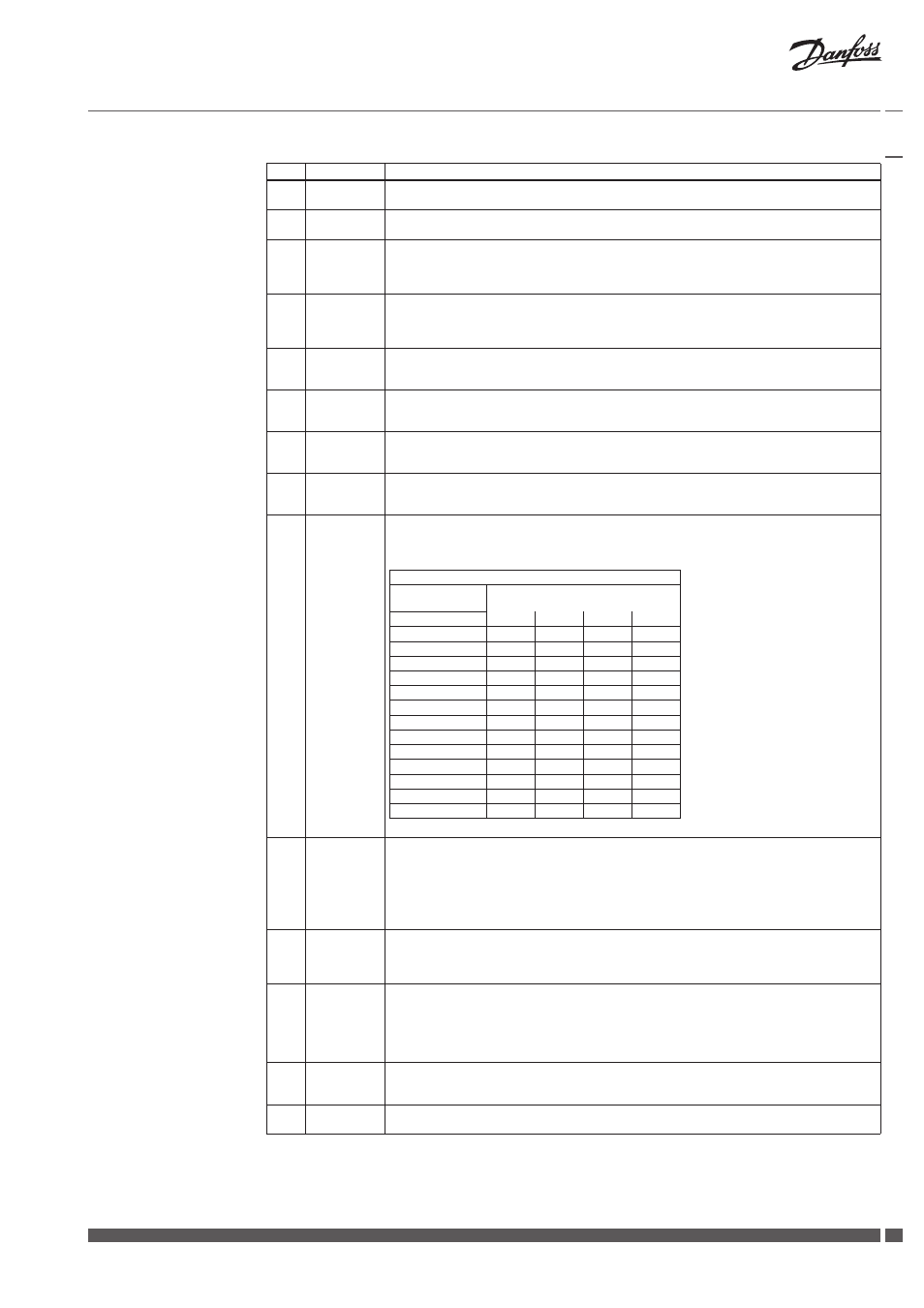

Cor Cal

S0 ….

…. °C

Sensor calibration: S0-S16 in range: ±9,9 °C

Do not make calibration when sensor cables are shorter then:

- for cable 0,75 mm

2

– 10 meters,

- for cable 1,00 mm

2

– 15 meters.

Correction factor

total length

(two - core cable)

cable cross section

(mm

2

)

in meter

0,5

0,75

1,00

1,5

10

- 0,2

- 0,1

- 0,1

- 0,1

15

- 0,5

- 0,3

- 0,2

- 0,1

20

- 0,4

- 0,3

- 0,2

- 0,1

25

- 0,5

- 0,3

- 0,3

- 0,1

30

- 0,6

- 0,4

- 0,3

- 0,2

35

- 0,7

- 0,5

- 0,4

- 0,2

40

- 0,8

- 0,5

- 0,4

- 0,2

45

- 0,9

- 0,6

- 0,5

- 0,2

50

- 1,0

- 0,7

- 0,5

- 0,3

75

- 1,5

- 1,0

- 0,8

- 0,4

100

- 2,0

- 1,4

- 1,0

- 0,5

125

- 2,5

- 1,7

- 1,3

- 0,6

150

- 3,0

- 2,0

- 1,5

- 0,8

Factory setting: 0 °C

33

Rel.Test

……….

Relay test (Triac output)

AUTO – normal working operation

V1-V16 – forced signal for valves output V1-V16

Rel C-NO - not used

T1 Out – not used

T2 Out – forced signal (24 VAC) for alarm T2.

Factory setting: Auto

34

AlertRel

... …

Alarm output (Triac)

StillOn – continuos alarm signal: T2 – 24 VAC

Pulse – pulse alarm signal 24 VAC every second

Factory setting: Pulse

35

Archiver

...

Information about data archiving:

Never – the feature is switched off,

1 File – data is stored in one file on the SD card,

2 Files – data is stored alternatively in two files to improve write reliability. This function decreases term of

date storage (twice).

Factory setting: 1 File

36

ArchFreq

...

Data archiving interval. The time can be set to any value between 10 seconds and 4 hours. The data from

each day saved in different files (with data name).

Factory setting: 1 min

37

BMSAdres

…..

CCR3 address in BMS system

Factory setting: 1