Table 3 – system pressures, Vacuum testing – York Millennium YK M3 M3 G4 THRU YK S6 S4 J2 User Manual

Page 50

50

YORK INTERNATIONAL

VACUUM TESTING

After the pressure test has been completed, the vacuum

test should be conducted as follows:

1. Connect a high capacity vacuum pump, with indi-

cator, to the system charging valve as shown in

Fig. 22 and start the pump. (See “Vacuum Dehydra-

tion”.)

2. Open wide all system valves, including the purge

and gauge valves. Be sure all valves to the atmo-

sphere are closed.

3. Operate the vacuum pump in accordance with

VACUUM DEHYDRATION until a wet bulb tempera-

ture of +32°F or a pressure of 5 mm Hg is reached.

See Table 3 for corresponding values of pressure.

4. To improve evacuation circulate hot water (not to

exceed 125°F) through the cooler and condenser

tubes to thoroughly dehydrate the shells. If a source

of hot water is not readily available, a portable wa-

ter heater should be employed. DO NOT USE

STEAM. A suggested method is to connect a hose

between the source of hot water under pressure

and the cooler head drain connection, out the cooler

vent connection, into the condenser head drain and

out the condenser vent. To avoid the possibility of

causing leaks, the temperature should be brought

up slowly so that the tubes and shell are heated

evenly.

5. Close the system charging valve and the stop valve

between the vacuum indicator and the vacuum

pump. Then disconnect the vacuum pump leaving

the vacuum indicator in place.

6. Hold the vacuum obtained in Step 3 in the system

for 8 hours; the slightest rise in pressure indicates

a leak or the presence of moisture, or both. If, after

8 hours the wet bulb temperature in the vacuum

indicator has not risen above 40°F or a pressure of

6.3 mm Hg, the system may be considered tight.

NOTE: Be sure the vacuum indicator is valved off

while holding the system vacuum and be

sure to open the valve between the vacuum

indicator and the system when checking

the vacuum after the 8 hour period.

7. If the vacuum does not hold for 8 hours within the

limits specified in Step 6 above, the leak must be

found and repaired.

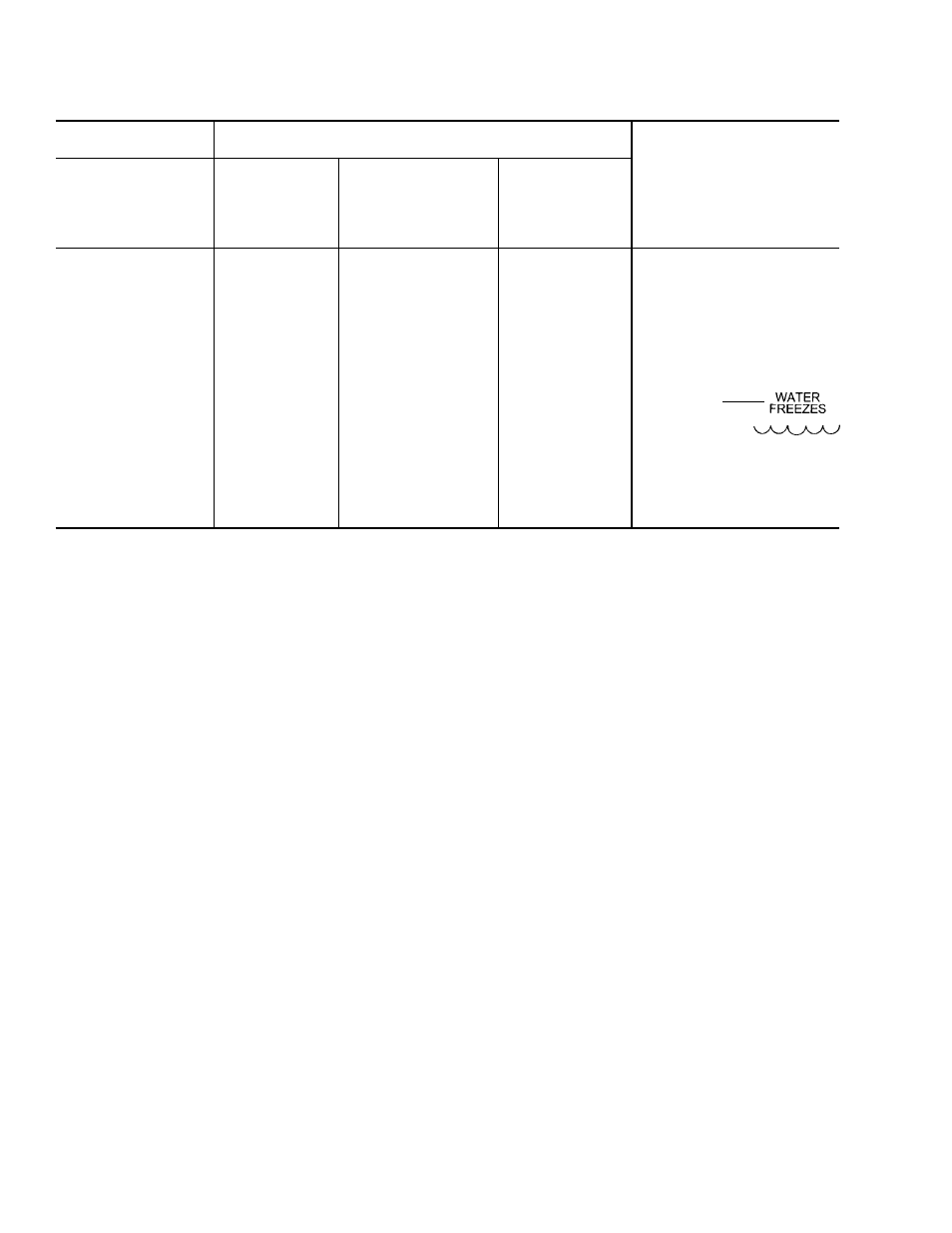

TABLE 3 –

SYSTEM PRESSURES

*GAUGE

ABSOLUTE

BOILING

INCHES OF

TEMPERATURES

MERCURY (HG)

MILLIMETERS

OF

BELOW ONE

PSIA

OF MERCURY

MICRONS

WATER

STANDARD

(HG)

°F

ATMOSPHERE

0

14.696

760.

760,000

212

10.24"

9.629

500.

500,000

192

22.05"

3.865

200.

200,000

151

25.98"

1.935

100.

100,000

124

27.95"

.968

50.

50,000

101

28.94"

.481

25.

25,000

78

29.53"

.192

10.

10,000

52

29.67"

.122

6.3

6,300

40

29.72"

.099

5.

5,000

35

29.842"

.039

2.

2,000

15

29.882"

.019

1.0

1,000

+1

29.901"

.010

.5

500

–11

29.917"

.002

.1

100

–38

29.919"

.001

.05

50

–50

29.9206"

.0002

.01

10

–70

29.921"

0

0

0

*One standard atmosphere

= 14.696 PSIA

= 760 mm Hg. absolute pressure at 32°F

= 29.921 inches Hg. absolute at 32°F

NOTES:

PSIA = Lbs. per sq. in. gauge pressure

= Pressure above atmosphere

PSIA = Lbs. per sq. in. absolute pressure

= Sum of gauge plus atmospheric pressure