Table 11: belt drive blower motor and drive data – York BQ 036 User Manual

Page 23

036-21508-005-A-0305

Unitary Products Group

23

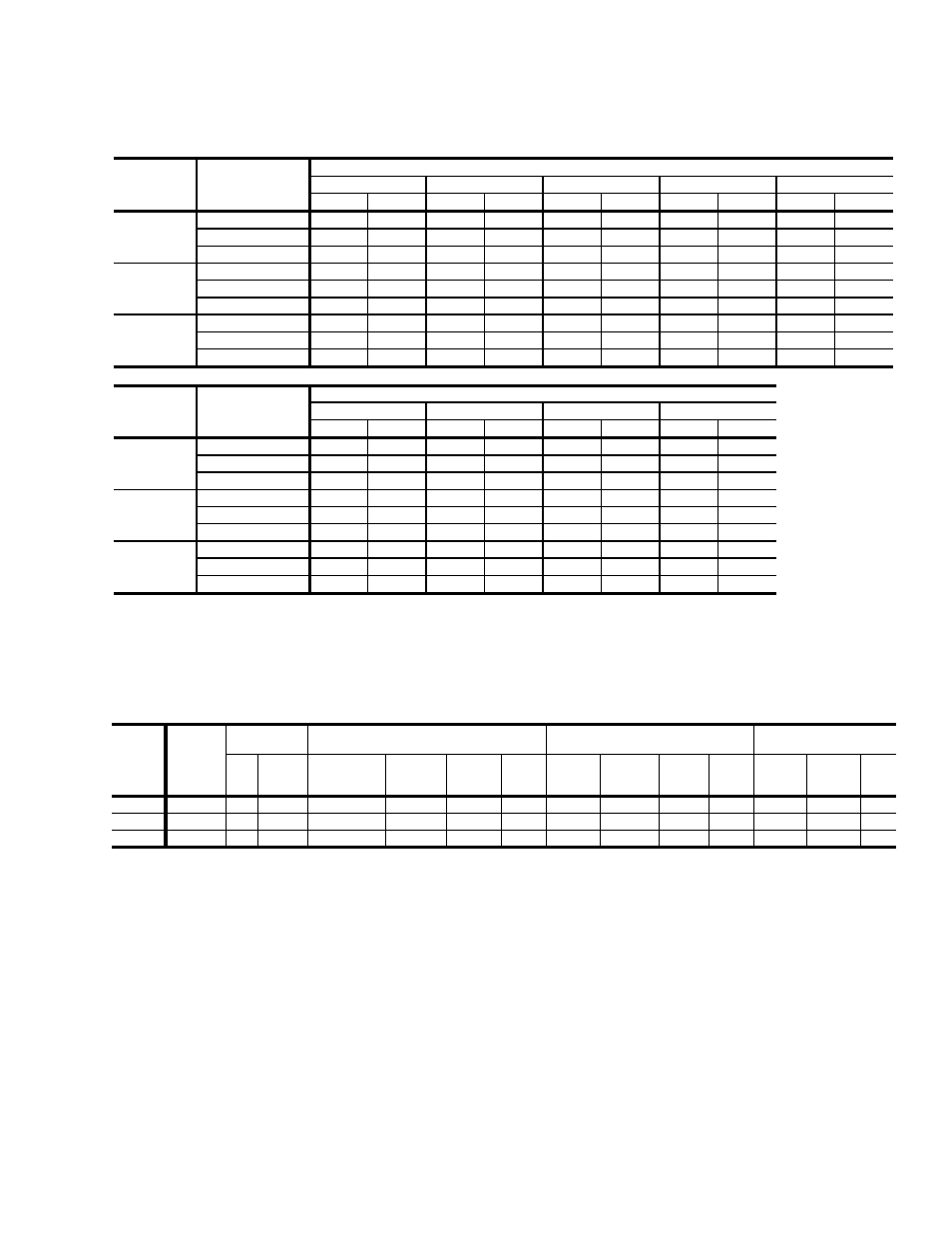

TABLE 10: SUPPLY AIR BLOWER PERFORMANCE (3 - 5 TON DIRECT DRIVE) - SIDE DUCT APPLICATION

CFM

WATTS

CFM

WATTS

CFM

WATTS

CFM

WATTS

CFM

WATTS

HI

-

-

-

-

-

-

1720

825

1665

795

MED

1660

850

1630

820

1590

780

1550

750

1500

720

LOW

1470

750

1440

725

1410

700

1370

675

1330

650

HI

-

-

-

-

2000

1010

1950

975

1905

945

MED

1810

910

1780

880

1740

850

1700

825

1665

800

LOW

1635

810

1610

780

1580

760

1555

740

1540

730

HI

-

-

-

-

2500

1400

2420

1350

2340

1300

MED

2390

1350

2350

1300

2300

1255

2245

1210

2190

1165

LOW

2270

1320

2230

1270

2190

1220

2145

1170

2090

1110

CFM

WATTS

CFM

WATTS

CFM

WATTS

CFM

WATTS

HI

1600

765

1540

735

1490

700

1380

670

MED

1450

690

1400

665

1360

650

1270

610

LOW

1290

625

1250

610

1220

600

1130

560

HI

1840

910

1770

825

1660

825

1530

775

MED

1620

775

1560

740

1480

700

1390

660

LOW

1510

715

1460

690

1400

660

1300

615

HI

2260

1250

2160

1190

2060

1135

1925

1065

MED

2130

1120

2065

1075

1990

1030

1900

970

LOW

2030

1070

1960

1020

1890

970

1810

920

3

1

4

1

0.70

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

2

0.90

0.80

1.00

3

1

4

1

5

1

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

2

5

1

0.60

0.20

0.30

0.40

0.50

UNIT

TONNAGE

MOTOR SPEED

UNIT

TONNAGE

MOTOR SPEED

1. Side Duct application (230/460/575 Volts)

2. Includes allowances for a wet evaporator coil, 1” filters, and the heat exchangers. Refer to STATIC RESISTANCES Table for resistance

values

.

TABLE 11: BELT DRIVE BLOWER MOTOR AND DRIVE DATA

MODEL

SIZE

BLOWER

RANGE

(RPM)

MOTOR

1

ADJUSTABLE MOTOR PULLEY

FIXED BLOWER PULLEY

BELT

(NOTCHED)

HP

FRAME

DESIG-

NATION

OUTSIDE

DIA.

(IN.)

PITCH

DIA.

(IN.)

BORE

(IN.)

DESIG-

NATION

OUTSIDE

DIA.

(IN.)

PITCH

DIA.

(IN.)

BORE

(IN.)

DESIG-

NATION

PITCH

LENGTH

(IN.)

QTY.

3 TON

790/1120

1 1/2

56

1VL40

2.7-3.7

2.4-3.4

5/8

AK61

5.9

5.7

1

A36

37.3

1

4 TON

790/1120

1 1/2

56

1VL40

2.7-3.7

2.4-3.4

5/8

AK61

5.9

5.7

1

A36

37.3

1

5 TON

850/1220

1 1/2

56

1VL40

2.7-3.7

2.4-3.4

5/8

AK56

5.4

5.2

1

A36

37.3

1

1. All motors have solid bases and are inherently protected. these motors can be selected to operate into their service factor because they are located

in the moving air, upstream of any heating device.