York E1FB240 User Manual

Page 8

3.

Turn the stem in (or clockwise) between 1/4 and 1/2 turn to

open the access port.

As soon as some internal pressure is relieved, close the ac-

cess port. DO NOT remove the entire holding charge.

NOTE: The copper disc on the liquid connection will prevent

any internal pressure from being relieved through the

main port of the liquid line stop valve.

If the unit has already lost its holding charge, it should be

leak tested and the necessary repairs should be made. If the

unit has maintained its holding charge, you can assume that

it has no leaks and proceed with the installation.

CAUTION: Dry nitrogen should always be supplied through a

connection while it is being brazed or unbrazed be-

cause the temperature required to make or break a

brazed joint is sufficiently high to cause oxidation

of the copper unless an inert atmosphere is pro-

vided. The flow of nitrogen should be continued

until the joint has cooled.

WARNING The dry nitrogen must always be supplied through

a pressure regulating valve.

Before installing the liquid line between the outdoor and in-

door units, remove the copper disc from the liquid connection

on the outdoor unit per the following procedure:

1.

Make sure the refrigerant in the line has been recovered

and that the liquid service valve on the unit is front-seated

and closed. The valve stem should be turned to its maxi-

mum clockwise position.

2.

Drill a small hole through the disc before unbrazing it to per-

mit a flow of dry nitrogen through the connection while it is

being unbrazed.

WARNING: This hole is also required to prevent the internal

pressure from building up as the disc is being un-

brazed and from blowing the disc off.

This warning applies to any disc being removed

from a service valve, coil connection, etc.

3.

Remove the cap from the 1/4" access port on the liquid line

stop valve.

4.

Connect a supply of dry nitrogen to this access port.

5.

Unbraze the copper disc from the liquid connection while

maintaining a minimum flow of dry nitrogen through the

connection.

After the disc has been removed,

1.

Burnish the external surfaces of the liquid connection on

the outdoor unit and the end of the field-supplied piping be-

ing used for the liquid line.

NOTE: Clean surfaces are essential for a well brazed connec-

tion.

2. Carefully clean the internal surfaces of the above. Any par-

ticles left on these surfaces may lead to a future system

malfunction.

NOTE: Use only copper tubing that has been especially

cleaned and dehydrated for refrigerant use. If the tub-

ing has been open for an extended period of time, it

should be cleaned before being used.

The liquid line connections can now be brazed while maintain-

ing a minimum flow of dry nitrogen through the piping.

NOTE: A filter-drier is factory-mounted in the outdoor unit for

the heating cycle and in the indoor unit for the cooling

cycle.

Do NOT install another filter-drier in the field-supplied

liquid line because refrigerant will flow in both direc-

tions on a heat pump system.

Recover the holding charge of the indoor unit and then remove

the sealing caps or discs from both its liquid and vapor connec-

tions per the following procedure:

1. Make sure the refrigerant in the lines has been recovered,

then drill a small hole through both the liquid disc and the

vapor disc. If the holding charge has already been lost, the

coil should be leak-tested and the necessary repairs

should be made.

2. Move the dry nitrogen supply from the access port on the

liquid line service valve of the outdoor unit to the hole

through the vapor disc on the indoor unit.

3. Unbraze the coil's liquid line disc while maintaining a flow of

dry nitrogen across the connection and through the hole in

the liquid line disc.

8

Unitary Products Group

035-16192-001-A-1001

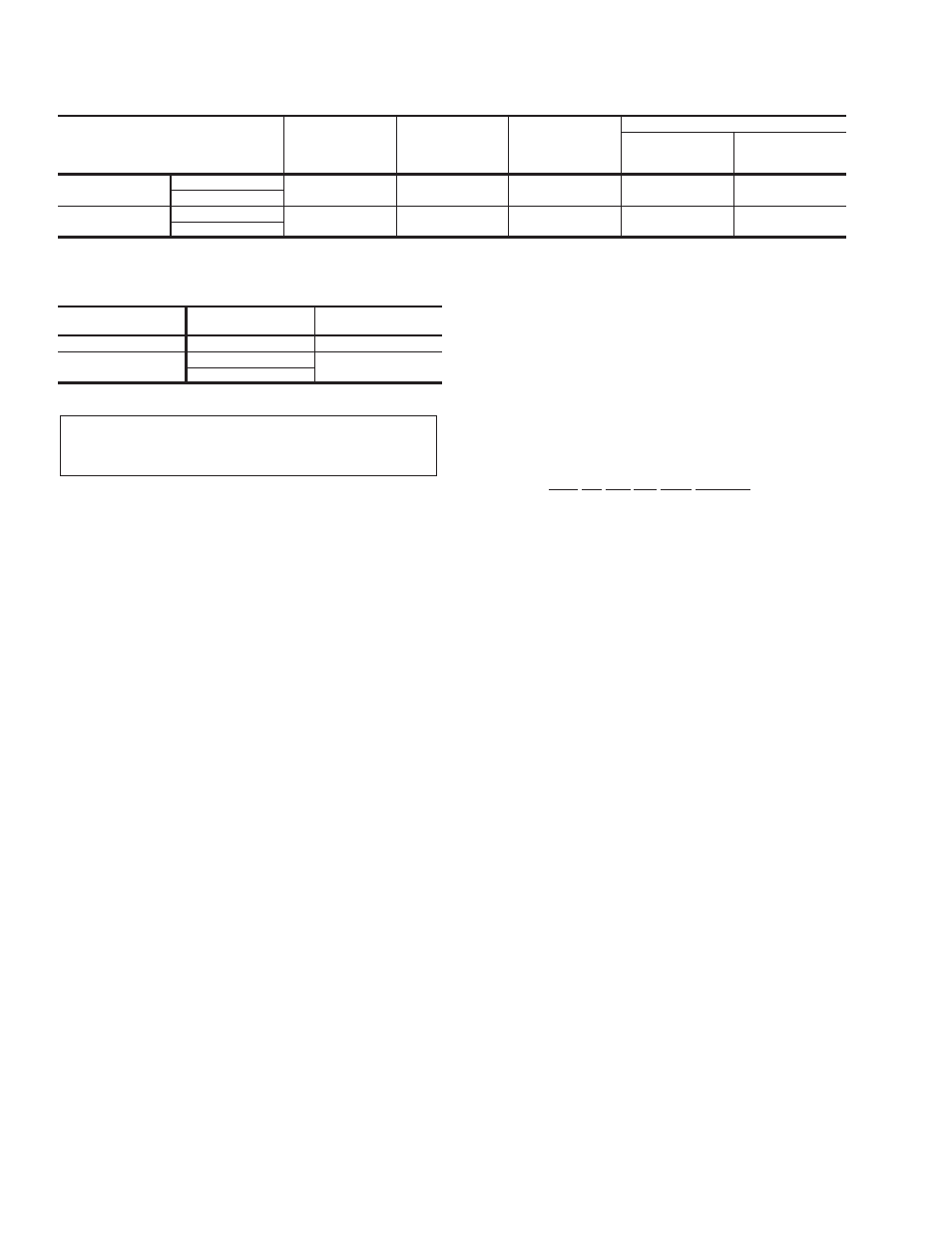

Refrigerant

Line

2

Line Size,

OD (In.)

Refrigerant Charge

(Lb/Ft)

Liquid

5/8

0.113

Vapor

1-1/8

0.013

1-3/8

1

Charges are based on 40

°

F suction temperature and 105

°

F liquid temperature.

2

Type “L” copper tubing.

TABLE 6 - REFRIGERANT LINE CHARGE

1

Use these line charges to adjust the system operating

charge when the refrigerant lines are more or less than the

25 feet listed in Table 2.

Model Designation

Nominal

Capacity

(Tons)

Refrigerant

Flow Rate

1

(Lbs./Min.)

Type L

Copper Tubing

(Inches O.D.)

Pressure Drop

3

Friction

2

(PSI/100 Ft.)

Vertical

Rise

(PSI/Ft.)

180

System 1

7-1/2

22.5

5/8

3.5

0.5

System 2

240

System 1

10

30.0

5/8

5.8

0.5

System 2

1

Based on Refrigerant-22 at the nominal capacity of the condensing unit, a liquid temperature of 105

°

F and a suction temperature of 40

°

F.

2

These friction losses do not include any allowances for a strainer, filter-drier, solenoid valve, isolation valve or fittings.

3

The total pressure drop of the liquid line for both friction and vertical rise must not exceed 40 PSI. If the pressure drop exceeds 40 PSI, the liquid refrigerant could flash before it reaches the

TABLE 5 - LIQUID LINES