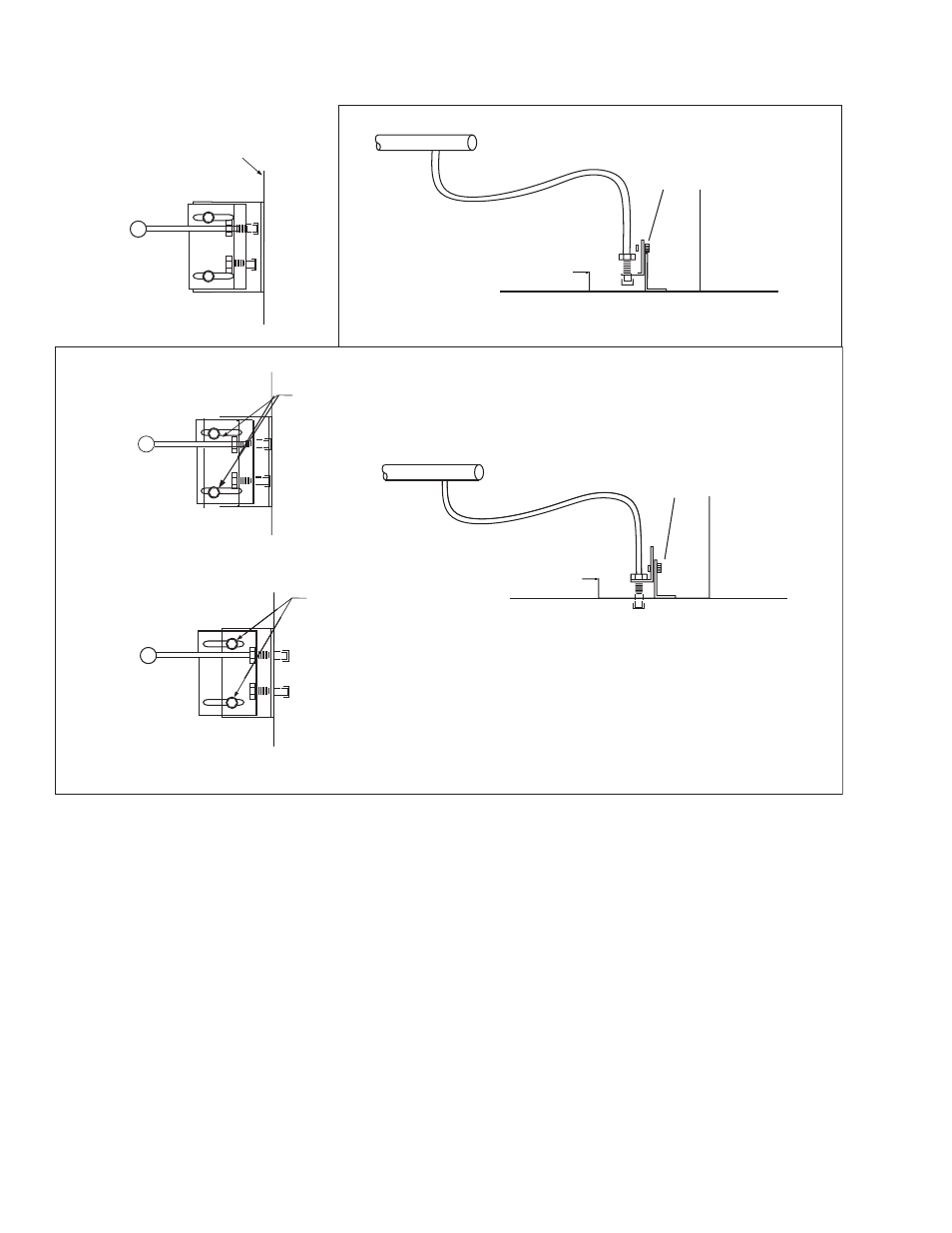

Service ports in shipping position, Service ports in installed position – York E1FB240 User Manual

Page 10

10

Unitary Products Group

035-16192-001-A-1001

COPPER

2 SCREWS

CORNER

POST

SERVICE PORTS IN SHIPPING POSITION

UNIT WALL

SIDE VIEW

COPPER

TUBE

UNIT

WALL

COPPER

2 SCREWS

CORNER

POST

TOP VIEW

UNIT

WALL

LOOSEN

SCREWS

SIDE VIEW

(AS SHIPPED)

PUSH SERVICE

PORTS THROUGH

CORNER POST

TIGHTEN SCREWS

SIDE VIEW

SERVICE PORTS

EXTENDED

(

)

SERVICE PORTS

EXTENDED

(

)

SERVICE PORTS IN INSTALLED POSITION

FIG. 5 - EXTENDING THE SERVICE PORTS

ALTERNATE CHARGING METHODS

If you are starting a unit when the ambient temperature is

higher or lower than those shown in Figures 7 through 15,

either of the following methods may be used.

Method 1: Determine the total weight of the refrigerant for

the total system by adding the required charge

for the outdoor unit, the indoor unit and the refrig-

erant lines using information in Tables 2 (Physi-

cal Data) and 6 (Refrigerant Line Charge).

Using the charging procedures outlined above,

weigh the required amount of refrigerant charge

into the unit.

Method 2: Install a field supplied moisture indicating sight

glass in the liquid line between the filter-drier and

the evaporator coil.

Using the charging procedure outlined above,

charge refrigerant until the moisture indicating

sight glass is clear. Add approximately 2 extra

pounds of refrigerant to assure a liquid refrigerant

seal at the expansion valve under all operating

conditions. Block the flow of the condenser air, if

necessary, to assure a head pressure of 280 psig

during the charging procedure.

Note:

The installer should return to the job to verify the operat-

ing charge when the ambient temperature is within the

conditions shown in Figures 7 through 15.